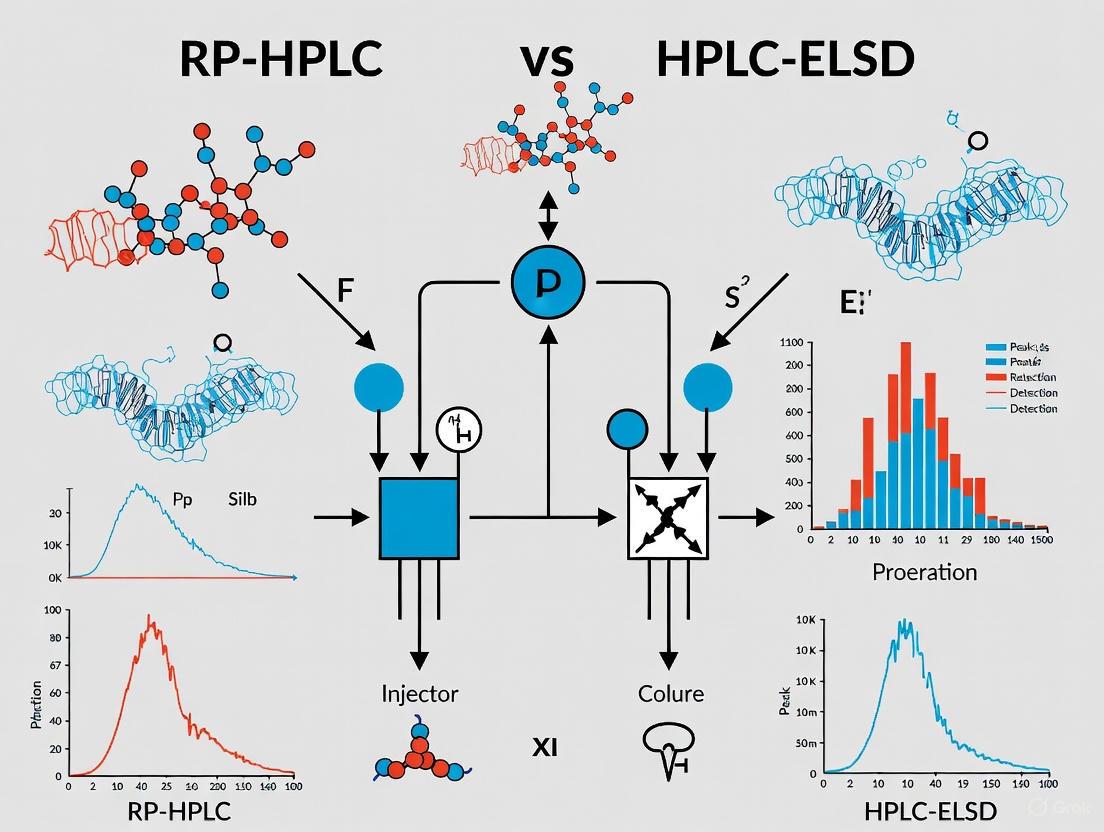

RP-HPLC vs. HPLC-ELSD for Protein Quantification: A Comprehensive Guide for Pharmaceutical Scientists

This article provides a systematic comparison of Reverse-Phase High-Performance Liquid Chromatography (RP-HPLC) and HPLC coupled with Evaporative Light Scattering Detection (HPLC-ELSD) for protein quantification in pharmaceutical formulations.

RP-HPLC vs. HPLC-ELSD for Protein Quantification: A Comprehensive Guide for Pharmaceutical Scientists

Abstract

This article provides a systematic comparison of Reverse-Phase High-Performance Liquid Chromatography (RP-HPLC) and HPLC coupled with Evaporative Light Scattering Detection (HPLC-ELSD) for protein quantification in pharmaceutical formulations. Tailored for researchers and drug development professionals, it explores the foundational principles of each technique, details methodological applications in complex systems like liposomes and lipid nanoparticles, and offers practical troubleshooting guidance. The content further delivers a rigorous validation and comparative analysis, evaluating performance parameters such as sensitivity, linearity, and robustness to empower scientists in selecting and optimizing the most appropriate quantification strategy for their specific protein-based products, from vaccines to novel biologics.

Core Principles: Understanding RP-HPLC and HPLC-ELSD in Protein Analysis

Fundamental Separation Mechanism of RP-HPLC for Proteins and Peptides

Reversed-phase high-performance liquid chromatography (RP-HPLC) is a dominant analytical and preparative technique for separating proteins and peptides, primarily based on their hydrophobicity. The separation mechanism involves the differential distribution of analyte molecules between a polar mobile phase (typically water mixed with organic solvents like acetonitrile or methanol) and a non-polar stationary phase (commonly silica beads bonded with C18, C8, or C4 alkyl chains) [1] [2].

For peptides and proteins, retention is governed by their solvophobic effect and on-off mechanism. In aqueous-rich mobile phases, hydrophobic regions of the molecule are adsorbed onto the stationary phase. Separation occurs as a gradient of increasing organic solvent reduces the polarity of the mobile phase, progressively desorbing analytes in order of increasing hydrophobicity [1]. This technique is exceptionally powerful for resolving structurally similar impurities, including deletion sequences, epimers, and modified peptides, which is critical in pharmaceutical development [3].

Detailed Separation Mechanism

The interaction between a peptide and the RP-HPLC system is a complex process that can be broken down into several key stages, as illustrated in the following workflow and detailed explanations.

Diagram Title: RP-HPLC Peptide Separation Mechanism Workflow

Hydrophobic Interaction and Adsorption

Upon injection in an aqueous-rich mobile phase, hydrophobic regions of the peptide molecule are repelled by the polar solvent (solvophobic effect) and driven toward the hydrophobic ligands of the stationary phase. The peptide is initially adsorbed or "trapped" on the column [1].

Critical Desorption and Elution

As the proportion of organic solvent (e.g., acetonitrile) in the mobile phase increases during a gradient run, the solvent strength increases. When the organic concentration reaches a critical point that disrupts the hydrophobic interactions for a specific peptide, that peptide rapidly desorbs and is carried by the mobile phase toward the detector. This characteristic is often described as an "on-off" or "critical" elution mechanism [1].

Order of Elution

Analytes elute in order of increasing overall hydrophobicity. Small changes in solvent strength can significantly impact retention, making gradient elution essential for resolving complex mixtures of peptides and proteins [4].

Key Experimental Parameters and Method Optimization

Successful RP-HPLC separation hinges on optimizing critical parameters that control selectivity, efficiency, and resolution.

Table 1: Key Experimental Parameters for RP-HPLC of Peptides and Proteins

| Parameter | Typical Options | Impact on Separation | Optimization Guidelines |

|---|---|---|---|

| Stationary Phase | C18, C8, C4, Phenyl, Biphenyl [5] [2] | C18: Highest retention; C8/C4: For large proteins; Aromatic phases: π-π interactions for aromatics [5] | Select based on analyte size: C4 for proteins >10 kDa; C8/C18 for peptides/small proteins [2]. |

| Pore Size | 100 Å, 130 Å, 200 Å, 300 Å [5] | Small pores exclude large molecules. Adequate pore size ensures analyte access to surface [6]. | Use 100-130 Å for peptides <5 kDa; 200-300 Å for larger proteins [6]. |

| Mobile Phase | Water-ACN or Water-MeOH with 0.1% TFA [1] | Organic Modifier: Elution strength; Ion-Pairing Agent (TFA): Improves peak shape by masking silanols & ion-pairing [1] [6]. | ACN generally provides better efficiency than MeOH. TFA is standard; formic acid preferred for MS compatibility [5]. |

| Gradient | 5-95% Organic in 10-120 min [4] | Steep gradients for speed; shallow gradients for complex mixtures or high resolution [4]. | Optimize gradient time and shape based on complexity. Shallow gradients near the elution % improve resolution. |

| Temperature | 30-60°C [4] | Higher temperature reduces viscosity, improves mass transfer, and can alter selectivity [4]. | Increase temperature to improve efficiency and reduce backpressure. |

| Column Hardware | Standard Stainless Steel vs. Bio-inert (PEEK, Titanium) [5] | Inert hardware prevents adsorption and poor recovery of metal-sensitive analytes (e.g., phosphorylated peptides) [5]. | Use bio-inert systems for sensitive analytes like phosphopeptides or for LC-MS applications [5] [7]. |

Essential Protocols

Protocol: Analytical RP-HPLC for Peptide Purity Analysis

This protocol is designed for the purity assessment of a synthetic peptide (e.g., 1-5 kDa).

Research Reagent Solutions & Materials:

- HPLC System: Bio-inert HPLC or UHPLC system with DAD or MS detector [5] [7]

- Analytical Column: e.g., Halo C18, 2.7 µm, 90 Å, 4.6 x 100 mm [5] or equivalent C8/C4 column

- Mobile Phase A: Ultrapure H₂O with 0.1% Trifluoroacetic Acid (TFA)

- Mobile Phase B: Acetonitrile (HPLC grade) with 0.1% TFA [1]

- Sample Solvent: Dilute aqueous TFA or initial mobile phase conditions

Procedure:

- Column Equilibration: Equilibrate the column with 5% Mobile Phase B for at least 10 column volumes at the method flow rate.

- System Setup: Set column temperature to 40-50°C. Set flow rate to 1.0 mL/min for a 4.6 mm ID column. Set detection wavelength to 214 nm (peptide bond) and/or 280 nm (aromatic residues).

- Gradient Elution:

- 0 min: 5% B

- 2 min: 5% B

- 45 min: 60% B (Linear gradient)

- 47 min: 95% B (Column cleaning)

- 50 min: 95% B

- 51 min: 5% B (Re-equilibration)

- 60 min: 5% B

- Injection: Inject 5-20 µL of sample (10-100 µg peptide).

- Data Analysis: Identify the main product peak and integrate impurity peaks. Purity is calculated as (Main peak area / Total peak area) × 100%.

Protocol: Method Development and Selectivity Optimization

This protocol uses column and mobile phase screening to achieve optimal separation of target peptides from closely related impurities [3].

Procedure:

- Initial Scouting: Run a fast, wide gradient (e.g., 5-95% B in 20 min) on a standard C18 column with a TFA/water/acetonitrile system to determine the approximate elution window.

- Column Screening: Test the sample on at least 3 columns with different selectivities (e.g., C18, Polar-embedded C18, Biphenyl) using the same gradient [5] [3].

- pH Screening: If selectivity is insufficient, test at two different pH values (e.g., pH 2 with TFA and pH 6-7 with phosphate or ammonium formate buffers). Note: Ensure column pH stability.

- Fine-Tuning: Optimize the gradient slope around the elution window of the target peptide. A shallower gradient (e.g., 1% B/min) enhances resolution.

- Orthogonality Assessment: For complex samples, employ 2D-LC, where the first dimension is RP-HPLC and the second dimension uses an orthogonal mode like HILIC or IEX [7].

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials and Reagents for RP-HPLC of Proteins/Peptides

| Item | Function/Application | Examples & Notes |

|---|---|---|

| Bio-inert HPLC System | Prevents analyte adsorption and loss for metal-sensitive species; essential for phosphopeptides, acidic proteins, and LC-MS [5] [7]. | Agilent InfinityLab Bio-Inert LC; Systems with PEEK or titanium flow paths [5]. |

| C18 Columns (Various Pores) | Workhorse stationary phase for most peptides and small proteins [2]. | Halo C18 (90 Å, 2.7 µm) [5]; Ascentis Express C18 (SPP, 160 Å). |

| C4/C8 Wide-Pore Columns | Analysis of larger proteins and hydrophobic peptides; reduced surface contact prevents irreversible adsorption [2]. | Vydac C4 (300 Å pore); Raptor C8 (2.7 µm, 90 Å) [5]. |

| Biphenyl Columns | Provides orthogonal selectivity via π-π interactions with aromatic residues; ideal for isomers and aromatics [5]. | Aurashell Biphenyl (SPP); Force Biphenyl. |

| Ion-Pairing Reagents | Modifies analyte charge, improves peak shape, and controls retention. | TFA (0.1%): Standard for preparative HPLC; Formic Acid (0.1%): MS-compatible [5] [6]. |

| MS-Compatible Buffers | Allows direct coupling of RP-HPLC to mass spectrometry for identification and characterization. | Ammonium formate, Ammonium acetate, Formic acid [7]. |

| Guard Columns | Protects expensive analytical columns from particulates and irreversibly bound contaminants. | Raptor Inert Guard Cartridges (matches analytical column chemistry) [5]. |

Application in a Broader Thesis Context: RP-HPLC vs. HPLC-ELSD

Within a thesis comparing RP-HPLC and HPLC-ELSD for protein quantification, understanding the fundamental mechanism of RP-HPLC is crucial because:

Detection Universality vs. Selectivity: RP-HPLC with UV detection (especially at 214 nm) leverages the peptide bond's absorbance, providing a universal and sensitive detection method that is directly influenced by the separation mechanism described above. In contrast, ELSD responds to the mass of non-volatile analyte, independent of chromophores. The "on-off" mechanism of RP-HPLC ensures that separated analytes enter the detector in pure, resolved bands, which is critical for accurate quantification in both detection modes.

Mobile Phase Constraints: The RP-HPLC mechanism requires volatile ion-pairing agents (TFA, formic acid) for desorption and elution. While these are compatible with ELSD, the presence of non-volatile buffers (e.g., phosphate) would disrupt the ELSD signal and is incompatible with the standard RP-HPLC mechanism, limiting method options.

Characterization Power: The RP-HPLC mechanism provides not just quantification but also a purity profile based on hydrophobicity. This is a significant advantage over a stand-alone ELSD measurement, as it can detect and quantify co-eluting impurities that might go unnoticed by ELSD alone. This makes RP-HPLC-UV a more comprehensive technique for quality control in drug development, as highlighted in USP-NF guidelines [8].

The detailed protocols and parameters provided here serve as the foundational methodology for the RP-HPLC arm of such a comparative study, enabling a fair and scientifically rigorous evaluation against the HPLC-ELSD technique.

The Operating Principle of ELSD as a Universal Detector for Non-Chromophoric Analytes

For researchers in drug development, the quantification of analytes lacking a chromophore, such as proteins, lipids, and carbohydrates, presents a significant analytical challenge. Standard UV detectors used in High-Performance Liquid Chromatography (HPLC) fail to detect these non-chromophoric compounds, creating a critical gap in analysis [9] [10]. The Evaporative Light Scattering Detector (ELSD) overcomes this limitation by serving as a near-universal detector for any non-volatile analyte, independent of its optical properties [11] [10]. Within the context of comparing Reversed-Phase HPLC (RP-HPLC) and HPLC-ELSD for protein quantification, understanding the operational principles of ELSD is fundamental. This application note details the core principles, optimized protocols, and key applications of ELSD, providing a structured resource for scientists developing robust quantification methods for biomolecules.

The Operating Principle of ELSD

The ELSD operates on a straightforward three-step principle that converts the column effluent into measurable signal based on the analyte's mass rather than its UV absorbance. The fundamental process and its corresponding logical workflow are illustrated below.

Core Operational Stages

- Step 1: Nebulization: The liquid effluent from the HPLC column is mixed with a controlled stream of inert gas (typically nitrogen) and passed through a narrow-bore needle to form a uniform dispersion of fine droplets [10]. This process ensures the analytes are prepared in a fine mist, which is crucial for the subsequent evaporation step.

- Step 2: Evaporation: The aerosol of droplets is then passed through a heated drift tube. Under controlled temperature, the volatile mobile phase (e.g., water, acetonitrile, methanol) completely evaporates, leaving behind a stream of dry, non-volatile analyte particles [12] [10]. This step effectively removes the solvent, eliminating its interference with detection.

- Step 3: Detection: The cloud of dried analyte particles is directed through a optical cell where it passes through a beam of light. The particles scatter the light, and this scattered light is captured by a photodetector (e.g., a photomultiplier tube) positioned at a specific angle [12] [10]. The intensity of the scattered light is proportional to the mass of the analyte present, enabling quantification.

Key Advantages and Quantitative Performance of ELSD

The principle of operation confers several major advantages over UV detection, particularly for the analysis of complex pharmaceutical formulations.

Universal Detection for Non-Chromophoric Analytes

Unlike UV detectors, ELSD does not rely on the presence of a chromophore. It can detect any non-volatile compound, including proteins, lipids, carbohydrates, and inorganic ions, making it indispensable for modern drug development where such molecules are common as APIs or excipients [9] [10]. For instance, ELSD has been successfully applied for the simultaneous determination of sodium and phosphate ions in aripiprazole injectable suspensions and for the quantification of lipid components in nanoparticle formulations, where UV detection often fails [12] [9].

Consistent Mass-Based Response

The ELSD response depends on the mass of the analyte particles rather than their molecular structure or extinction coefficients. This provides a more consistent response factor across similar quantities of different analytes, offering a more accurate indication of relative quantities in a sample compared to UV, where response factors can vary dramatically [10].

Compatibility with Gradient Elution

Since the mobile phase is evaporated before detection, there is little to no baseline drift during gradient elution [10]. This is a significant advantage over refractive index (RI) detection and allows for the use of a wider range of solvents, including those with high UV cut-offs, to achieve specific polarities and separations [9] [10].

Table 1: Key Advantages of ELSD Over UV Detection for Problematic Analytes

| Feature | ELSD | UV Detector |

|---|---|---|

| Detection Principle | Light scattering by solid particles | Photon absorption by chromophores |

| Applicability | Universal for non-volatile compounds | Limited to UV-absorbing compounds |

| Response Factor | More uniform for similar masses | Highly dependent on extinction coefficient |

| Gradient Elution | Excellent baseline stability | Can cause significant baseline drift |

| Solvent Restrictions | Can use high UV-cut-off solvents | Limited by solvent UV transparency |

Validation studies demonstrate that HPLC-ELSD methods can meet rigorous regulatory standards. One study for lipid nanoparticle analysis reported excellent linearity (R² ≥ 0.997), precision (relative standard deviation < 5%), and accuracy (recoveries between 92.9–108.5%) [9]. Similarly, a method for inorganic ions showed acceptable linearity (R² > 0.99), precision (RSD < 10%), and accuracy (recoveries of 95–105%) in accordance with ICH guidelines [12].

Experimental Protocol: Protein Quantification in Liposomal Formulations

This protocol outlines the use of HPLC-ELSD for determining protein encapsulation efficiency within liposomal formulations, a critical quality attribute in biopharmaceutical development [13].

Research Reagent Solutions

Table 2: Essential Materials and Reagents for HPLC-ELSD Analysis of Proteins and Lipids

| Item | Function/Application | Example Specifications |

|---|---|---|

| HPLC-ELSD System | Integrated system for separation and detection | Shimadzu Prominence-I with ELSD-LTIII or equivalent [12] |

| Analytical Column | Stationary phase for analyte separation | Poroshell C18 (for lipids) [9]; Trimodal columns (e.g., Amaze TH) for ions [12] |

| Nitrogen Gas Supply | Nebulizing and evaporating gas for ELSD | High-purity grade, regulated pressure (e.g., 3.2 bar) [12] |

| Ammonium Formate/Formic Acid | Mobile phase buffers for separation | e.g., 20 mM HCOONH4, pH adjusted to 3.2 with formic acid [12] |

| Acetonitrile/Methanol | Organic mobile phase components | HPLC gradient grade [12] [9] |

| Protein Standards | Calibration and method validation | Relevant protein or lipid standards of known purity [13] |

Detailed Methodology

Sample Preparation

- Liposome Processing: Dilute the liposomal formulation with an appropriate solvent (e.g., ethanol or a buffered solution) to disrupt the vesicles and release the encapsulated protein. Gently mix and centrifuge if necessary to remove any particulates [9].

- Standard Solutions: Prepare a series of standard solutions of the protein of interest by diluting a stock standard solution in the same solvent as the samples. The concentration range should cover the expected levels in the test samples (e.g., 50–150% of the target concentration) [12].

- Filtration: Filter all standards and samples through a 0.45 μm PTFE syringe filter prior to injection to prevent column clogging and particulate contamination of the ELSD [12].

HPLC-ELSD Instrumental Configuration

- Column: A reversed-phase C18 column (e.g., 150 mm x 4.6 mm, 2.7 μm) is suitable for many protein and lipid separations. Column temperature should be maintained at 40-50°C [9].

- Mobile Phase: Utilize a gradient elution. For example:

- Mobile Phase A: 0.1% Trifluoroacetic Acid (TFA) in Water.

- Mobile Phase B: 0.1% TFA in Acetonitrile.

- Gradient: Program from 30% B to 95% B over 10-15 minutes [9].

- ELSD Parameters: Optimize the following settings for maximum signal-to-noise ratio:

Data Analysis and Quantification

- System Suitability: Before analysis, inject a system suitability test solution to ensure the resolution, peak shape, and detector response are within specified limits [12].

- Calibration Curve: Inject the standard solutions in triplicate. Plot the logarithm of the peak area against the logarithm of the analyte concentration. The relationship is often non-linear but can be modeled using a power function or log-log plot [9].

- Quantification: Inject the prepared test samples. Calculate the concentration of the protein in the samples using the established calibration curve. Report the encapsulation efficiency based on the total protein input during liposome preparation.

Application in Pharmaceutical Analysis

The HPLC-ELSD technique has proven its value in diverse, challenging analytical scenarios within pharmaceutical research and quality control.

- Quantification of Inorganic Ions: A trimodal column coupled with ELSD enabled the simultaneous analysis of sodium and phosphate ions in a complex aripiprazole injectable suspension, overcoming the limitations of UV detection for these ions [12].

- Lipid Nanoparticle (LNP) Characterization: HPLC-ELSD is critical for monitoring the composition and quality of LNPs used in mRNA vaccines and drug delivery. It allows for the simultaneous quantification of ionizable lipids, phospholipids, cholesterol, and PEG-lipids, which often have weak or no UV chromophores [9].

- Protein Loading Determination: As directly relevant to the thesis context, HPLC-ELSD has been established as a reliable technique for the rapid determination of protein loading in liposomal formulations, providing a vital tool for optimizing encapsulation processes [13].

The Evaporative Light Scattering Detector is a powerful analytical tool that effectively addresses the critical challenge of detecting and quantifying non-chromophoric analytes. Its universal detection principle, compatibility with gradient elution, and consistent mass-based response make it an indispensable component in the modern pharmaceutical laboratory. For research focused on comparing protein quantification techniques, the detailed operational principles and robust protocols provided here for HPLC-ELSD establish a foundational framework for generating reliable, high-quality data essential for advanced drug development.

Key Advantages and Inherent Limitations of Each Detection System

Reversed-Phase High-Performance Liquid Chromatography (RP-HPLC) coupled with various detection systems is a cornerstone technique for protein quantification in pharmaceutical development. The selection of an appropriate detection system is critical, as it directly impacts the accuracy, sensitivity, and robustness of the analytical method. For protein analytes lacking strong chromophores, Evaporative Light Scattering Detection (ELSD) offers a viable alternative to ubiquitous ultraviolet (UV) detection. This application note provides a detailed comparative analysis of RP-HPLC with UV and ELSD detection, framing their respective advantages and limitations within the context of protein quantification for liposomal and other complex biological formulations. Supported by experimental protocols and analytical data, this document serves as a guide for researchers and drug development professionals in selecting and implementing the optimal detection strategy for their specific protein analysis needs.

Technical Comparison: RP-HPLC-UV vs. HPLC-ELSD

The core distinction between these detection systems lies in their fundamental principles of operation. RP-HPLC-UV detects analytes based on their absorption of ultraviolet light, whereas HPLC-ELSD is an evaporative aerosol detector that measures the light-scattering properties of non-volatile analyte particles after nebulization and evaporation of the mobile phase [14] [15].

Table 1: Comparative Technical Specifications for Protein Quantification

| Feature | RP-HPLC with UV Detection | HPLC with ELSD Detection |

|---|---|---|

| Detection Principle | Absorption of ultraviolet light by chromophores [14] | Light scattering by non-volatile particles post-mobile-phase evaporation [14] [15] |

| Universal Detection | No, requires UV-absorbing moieties [11] | Yes, for any non-volatile analyte [16] |

| Typical LOD/LOQ for Proteins | Generally low (e.g., <10 µg/mL for OVA [14]) | Generally higher than UV (e.g., <10 µg/mL for OVA [14]) |

| Linear Dynamic Range | Wide, typically over several orders of magnitude | Narrower, often sigmoidal, typically 1-2 orders of magnitude [15] |

| Response Uniformity | Dependent on molar absorptivity; varies by protein | More uniform; less dependent on chemical structure [15] |

| Compatibility with Gradients | Excellent | Excellent [11] [17] |

| Key Advantage | High sensitivity for proteins with chromophores; wide linear range | Universal detection for non-volatile analytes without chromophores |

| Key Limitation | Cannot detect proteins lacking chromophores | Lower sensitivity; non-linear response complicates quantification [15] |

| Ideal Use Case | Quantifying proteins with aromatic amino acids (e.g., OVA) | Quantifying proteins, lipids, or carbohydrates without chromophores [14] [17] |

Table 2: Performance in Liposomal Protein Formulation Analysis [14]

| Performance Metric | RP-HPLC | BCA Assay | HPLC-ELSD |

|---|---|---|---|

| Linearity (R²) | >0.99 | >0.99 | >0.99 |

| Limit of Quantification (LOQ) | <10 µg/mL | <10 µg/mL | <10 µg/mL |

| Analysis Type | Direct | Direct | Direct |

| Interference from Lipids | Low | Reported [14] | Low |

Advantages and Limitations in Detail

Key Advantages of RP-HPLC-UV

RP-HPLC-UV is the most prevalent separation and detection technique in analytical laboratories [18]. Its advantages are numerous:

- High Sensitivity and Specificity: For proteins containing UV-absorbing amino acids (tryptophan, tyrosine, phenylalanine), UV detection at 280 nm provides exceptionally high sensitivity and specificity [14] [11].

- Wide Linear Dynamic Range: The detector response is typically linear over a wide concentration range, simplifying calibration and quantification across diverse sample types [15].

- Excellent Precision and Robustness: The technique delivers highly reproducible retention times and peak areas, making it indispensable for quality control (QC) applications in regulated environments like pharmaceutical manufacturing [11].

- Well-Established and Understood: The principles and methodologies are familiar to most practitioners, with a vast body of literature and application notes for support.

Inherent Limitations of RP-HPLC-UV

- Lack of Universality: The most significant limitation is its dependence on the presence of a chromophore. Proteins or peptides lacking sufficient aromatic amino acids will yield a weak or non-detectable signal [11].

- Potential for Interference: Other UV-absorbing compounds in complex sample matrices (e.g., excipients, buffers) can interfere with the analysis, requiring more extensive sample purification [14].

Key Advantages of HPLC-ELSD

HPLC-ELSD addresses the primary shortcoming of UV detection.

- Universal Detection for Non-Volatile Analytes: ELSD can detect any non-volatile or semi-volatile compound, regardless of its optical properties. This makes it ideal for proteins, lipids, carbohydrates, and other molecules without a chromophore [14] [16] [17].

- Compatibility with Gradient Elution: Unlike some universal detectors (e.g., Refractive Index), ELSD performs robustly with gradient elution, which is often essential for separating complex protein mixtures [11] [17].

- Robustness and Simpler Operation: Compared to mass spectrometry (MS), ELSD is a lower-cost, more robust detector with easier maintenance, making it suitable for routine QC activities [17].

Inherent Limitations of HPLC-ELSD

- Lower Sensitivity: ELSD generally has higher limits of detection compared to UV, as the signal depends on the mass of the analyte particle after evaporation [15].

- Non-Linear Response: The detector response is often sigmoidal or exponential, requiring logarithmic transformation or power function fitting for accurate quantification, which adds complexity to data analysis [15].

- Narrower Dynamic Range: The usable linear range is typically limited to one or two orders of magnitude, compared to several for UV detection [15].

- Destructive Technique: The sample is nebulized and evaporated, preventing its recovery for further analysis.

Experimental Protocols

This protocol is adapted from a study comparing methods for quantifying ovalbumin (OVA) loading in liposomal formulations.

4.1.1 Research Reagent Solutions

| Item | Function |

|---|---|

| Jupiter C18 Column (300 Å, 4.60 × 150 mm) | Stationary phase for reversed-phase separation of proteins. |

| Ovalbumin (OVA) | Model antigen for method development and validation. |

| Trifluoroacetic Acid (TFA), HPLC Grade | Ion-pairing agent and mobile phase modifier. |

| HPLC Grade Methanol and Water | Components of the mobile phase for gradient elution. |

| Liposomal Formulations | Neutral, anionic, and cationic liposomes containing OVA. |

4.1.2 Methodology

- Chromatographic Conditions:

- Column: C18 column (e.g., 150 × 4.6 mm).

- Mobile Phase: Solvent A (0.1% TFA in water), Solvent B (100% methanol).

- Gradient: 0-10 min: 100% A; 10.1-15 min: 100% B; 15.1-20 min: 100% A.

- Flow Rate: 1.0 mL/min.

- Detection: UV at 280 nm.

- Injection Volume: 20 µL.

- Temperature: Ambient.

Sample Preparation:

- Liposomal samples are disrupted using a suitable solvent (e.g., methanol) to release encapsulated protein.

- The sample is centrifuged to precipitate lipids and other insoluble components.

- The supernatant is directly injected into the HPLC system.

Validation:

- Linearity: Prepare OVA standards in the concentration range of 1-100 µg/mL. Plot peak area versus concentration to generate a calibration curve with R² > 0.99.

- LOD/LOQ: Calculate using the standard deviation of the response and the slope of the calibration curve (e.g., LOD = 3.3σ/S; LOQ = 10σ/S).

Figure 1: RP-HPLC-UV Workflow for Liposomal Protein Analysis.

This protocol outlines the use of ELSD for quantifying proteins like OVA, which can also be applied to metabolites and other non-chromophoric compounds.

4.2.1 Research Reagent Solutions

| Item | Function |

|---|---|

| Poroshell 120 SB-C18 (75 × 4.6 mm, 2.7 µm) | Stationary phase for fast, efficient separations. |

| Ovalbumin (OVA) or Target Metabolites | Analytic of interest. |

| Formic Acid (FA), HPLC Grade | Mobile phase modifier for improved separation. |

| HPLC Grade Acetonitrile, Methanol, Water | Mobile phase components. |

| Nitrogen Gas Source | High-purity gas for ELSD nebulizer and evaporator. |

4.2.2 Methodology

- Chromatographic Conditions:

- Column: C18 column (e.g., 75 × 4.6 mm, 2.7 µm).

- Mobile Phase: Solvent A (0.1% Formic acid in water), Solvent B (Acetonitrile).

- Gradient: Optimized for 8-minute run time.

- Flow Rate: 0.5 - 1.0 mL/min.

- Injection Volume: 5 µL.

ELSD Parameters:

- Evaporator Temperature: Optimized for mobile phase composition (e.g., 40-60°C).

- Nebulizer Temperature: Set appropriately for consistent aerosol formation.

- Gas Flow Rate: Nitrogen, typically 1.0-1.5 SLM (Standard Liters per Minute).

- Gain: Set for optimal signal-to-noise (e.g., 8 [14]).

Sample Preparation:

- For urine or biological fluids: Deproteinize sample with perchloric acid (PCA), vortex, centrifuge, and inject supernatant [16].

- For liposomal formulations: Similar disruption and centrifugation as in Protocol 4.1.2.

Validation:

- Linearity: Prepare standards and plot log(peak area) vs. log(concentration) or use a power function fit due to the non-linear response.

- Assess precision, accuracy, and determine LOD/LOQ with low-level standards.

Figure 2: HPLC-ELSD Detection Process Flow.

Defining Ideal Use-Case Scenarios for UV vs. Light Scattering Detection

The accurate quantification of proteins is a cornerstone of biopharmaceutical development, yet selecting the optimal analytical technique presents a significant challenge for researchers. Within the context of high-performance liquid chromatography (HPLC), the choice between ultraviolet (UV) detection and evaporative light scattering detection (ELSD) requires careful consideration of the specific analytical problem. This application note provides a structured framework for this decision-making process, offering detailed experimental protocols and a clear comparison of performance characteristics to guide scientists in method selection for protein quantification.

Table 1: Core Principles of UV and Light Scattering Detection Techniques

| Feature | UV Detection | Evaporative Light Scattering Detection (ELSD) |

|---|---|---|

| Fundamental Principle | Measures absorbance of light by chromophores in the analyte [19] | Measures light scattered by non-volatile analyte particles after nebulization and evaporation of the mobile phase [20] [21] |

| Detection Dependency | Dependent on the presence of UV-absorbing chromophores (tryptophan, tyrosine) [19] | Mass-dependent; independent of chromophores [20] |

| Linearity | Directly proportional to concentration (Beer-Lambert Law) [19] | Non-linear; requires log-log transformation for calibration [21] |

| Impact on Sample | Non-destructive [19] | Destructive |

Comparative Detector Performance

The choice between UV and ELSD significantly impacts key performance parameters. A comparison of these techniques for analyzing anti-diabetic drugs revealed that ELSD and its advanced counterpart, charged aerosol detection (CAD), can offer superior performance in certain metrics. CAD was found to provide the best accuracy and limit of detection (LOD) among the detectors studied, with its LOD being up to two times higher than that of ELSD [22]. In protein quantification for liposomal formulations, both RP-HPLC (typically with UV) and HPLC-ELSD demonstrated strong linear responses with correlation coefficients of 0.99, and limits of quantification (LOQ) below 10 µg/mL for both methods [23] [24].

Table 2: Quantitative Performance Comparison for Protein and Related Analyses

| Performance Parameter | UV Detection | HPLC-ELSD | Notes and Context |

|---|---|---|---|

| Linearity | R² > 0.99 [22] | R² > 0.99 [23] [17] | ELSD requires log-log plot [21]. |

| Limit of Detection (LOD) | Compound-dependent | Can be higher than UV for some compounds [22] | CAD, a similar aerosol-based detector, showed a LOD up to 2x higher than ELSD [22]. |

| Precision | Good precision, especially at higher concentrations [22] | Good precision; RSD < 5% reported for lipids [17] | |

| Key Advantage | High sensitivity for chromophores, broad linear range [20] | Universal detection for non-volatile analytes [20] [16] | Does not require derivatization. |

Ideal Use-Case Scenarios

Recommended Scenarios for UV Detection

- Proteins with Strong Chromophores: The ideal application for UV detection is the quantification of proteins and peptides containing sufficient aromatic amino acids (tryptophan and tyrosine) in a purified solution [19]. This method is rapid, cost-effective, and non-destructive, allowing for sample recovery.

- Routine Quality Control with Defined Standards: For well-characterized proteins where the presence of chromophores is certain and the method has been validated, UV detection offers high throughput and ease of use [19].

- Detection of Impurities with Chromophores: When monitoring for known impurities or degradation products that also contain UV-absorbing groups, UV detection is highly effective.

Recommended Scenarios for Light Scattering Detection (ELSD)

- Analytes Lacking Chromophores: ELSD is the superior choice for molecules without a useful chromophore. This includes lipids [17], carbohydrates [21], and synthetic polymers used in drug delivery systems [20].

- Universal Detection in Complex Formulations: When analyzing complex formulations like lipid nanoparticles (LNPs) or liposomes, ELSD can simultaneously quantify multiple excipients regardless of their optical properties—such as ionizable lipids, phospholipids, cholesterol, and PEGylated lipids—within a single run [17].

- Gradient Elution with Non-UV Absorbing Solvents: ELSD is compatible with gradient elution, and its response is unaffected by the optical transparency of the mobile phase, unlike UV detection which can be limited by solvent UV cut-offs [20] [21].

Experimental Protocols

Protocol for Protein Quantification in Liposomes using HPLC-ELSD

This protocol, adapted from research on liposomal protein delivery, describes a direct method for quantifying protein encapsulation [23] [24].

4.1.1 Research Reagent Solutions

Table 3: Essential Reagents and Materials

| Item | Function/Description | Example |

|---|---|---|

| HPLC-ELSD System | Instrumentation for separation and detection. | System equipped with binary pump, autosampler, and ELSD. |

| C18 Column | Stationary phase for reversed-phase separation. | Phenomenex Jupiter C18 (150 × 4.6 mm, 5 µm) [23]. |

| Mobile Phase Solvents | Elution of analytes from the column. | Solvent A: 0.1% Trifluoroacetic Acid (TFA) in water. Solvent B: Methanol or Acetonitrile. |

| Protein Standard | For calibration curve generation. | Ovalbumin (OVA) [23]. |

| Lipid Solvents | For dissolving lipid films or as organic phase in microfluidics. | Methanol, Ethanol. |

| Purification Device | For removing unencapsulated protein. | Dialysis tubing or centrifugal filters. |

4.1.2 Step-by-Step Procedure

- Liposome Preparation and Purification: Prepare protein-loaded liposomes using your method of choice (e.g., microfluidics, lipid film hydration). Purify the formed liposomes via dialysis or size-exclusion chromatography to remove unencapsulated protein.

- Liposome Solubilization: Solubilize the purified liposomal formulation using an appropriate solvent (e.g., methanol) to release the encapsulated protein into solution. Gently vortex and centrifuge if necessary.

- Chromatographic Separation:

- Column: C18 column (e.g., 150 × 4.6 mm, 5 µm).

- Mobile Phase: Utilize a gradient. Example: Start at 100% A (0.1% TFA in water), transition to 100% B (methanol) over 10 minutes, hold, and re-equilibrate.

- Flow Rate: 1 mL/min.

- Column Temperature: Ambient or controlled (e.g., 50°C).

- Injection Volume: 20 µL of the solubilized sample.

- ELSD Detection:

- Drift Tube Temperature: Set according to mobile phase volatility (e.g., 40-60°C).

- Nebulizer Gas Pressure (N₂): Optimize for stable signal (e.g., 3.5 bar).

- Gain: Set appropriately (e.g., 8-9).

- Data Analysis: Generate a calibration curve by injecting a series of known concentrations of the standard protein (e.g., OVA). Plot the logarithm of the peak area against the logarithm of the concentration. Use this curve to determine the protein concentration in the solubilized liposome samples.

Protocol for Rapid Sugar Profiling in Foods using HPLC-ELSD

This protocol highlights the application of ELSD for analytes completely lacking chromophores [21].

4.2.1 Research Reagent Solutions

Table 4: Essential Reagents and Materials for Sugar Analysis

| Item | Function/Description | Example |

|---|---|---|

| HPLC-ELSD System | As in Protocol 4.1. | |

| HILIC or NH₂ Column | Stationary phase for polar compound separation. | Suitable for carbohydrate separation. |

| Sugar Standards | For calibration. | Fructose, Glucose, Sucrose. |

| Mobile Phase | Elution of sugars. | Acetonitrile and Water mixtures. |

4.2.2 Step-by-Step Procedure

- Sample Preparation: Extract and dilute food samples (e.g., fruit, honey) in an appropriate solvent (e.g., water, acetonitrile/water mixture). Centrifuge and filter (0.2 µm PVDF filter) before injection.

- Chromatographic Separation:

- Column: A column suitable for carbohydrate separation (e.g., HILIC or amino-silica).

- Mobile Phase: Isocratic or gradient of acetonitrile and water.

- Flow Rate: 0.5 - 1.0 mL/min.

- ELSD Detection:

- Drift Tube Temperature: Optimize for acetonitrile/water evaporation (e.g., 50°C).

- Gas Pressure: Typically 3.5 bar for N₂.

- Data Analysis: As described in Section 4.1.2, Step 5, using a log-log calibration curve for each sugar.

UV and light scattering detection techniques are complementary tools in the analytical scientist's arsenal. UV detection remains the method of choice for its simplicity, linearity, and non-destructive nature when analyzing proteins with intrinsic chromophores in relatively pure solutions. In contrast, ELSD provides a powerful, universal detection alternative for challenging analyses involving proteins lacking chromophores, complex drug delivery formulations containing lipids and polymers, or small molecules like carbohydrates. By applying the decision workflow and validated protocols outlined in this application note, researchers can make informed, rational choices between these techniques to ensure accurate and reliable protein quantification in their specific use-case scenario.

From Theory to Practice: Implementing Methods in Complex Formulations

Direct vs. Indirect Quantification of Protein Encapsulation in Liposomes

The accurate determination of protein encapsulation efficiency (EE) is a critical step in the development of liposomal drug delivery systems. Traditional indirect quantification methods, which calculate entrapped protein by measuring the non-incorporated drug and subtracting from the initial amount, often yield inaccurate and misrepresentative results due to the mass balance assumption. This application note provides a comparative analysis of direct quantification techniques, including RP-HPLC and HPLC-ELSD, highlighting their advantages over indirect approaches. We present optimized protocols for these methods and demonstrate their application in the rapid, robust determination of protein loading within liposomal formulations, supporting accelerated development of protein-based therapeutics.

Liposomes are well-recognized for their efficacy in drug delivery, with growing interest in their application for vaccine development and protein therapeutic delivery [23]. The successful development of these formulations depends heavily on accurate determination of encapsulation efficiency (EE), which indicates the percentage of successfully incorporated protein relative to the initial amount used in preparation.

The quantification challenge arises from the need to distinguish between encapsulated protein and free protein in suspension. Indirect quantification methods, which remain commonplace, measure protein encapsulation by quantifying the amount of non-incorporated drug following separation techniques (e.g., centrifugation, dialysis, or chromatography), then subtracting this value from the initial protein amount [23]. This approach presents significant limitations as it assumes mass balance is achieved and that all protein not measured in the free fraction is associated with the delivery vesicles—assumptions that frequently lead to inaccurate results [23] [25].

Direct quantification methods overcome these limitations by directly measuring the protein entrapped within the liposomal structure after removing the unencapsulated fraction, providing more reliable and accurate encapsulation data [23]. This note details protocols for both approaches, with emphasis on establishing robust direct quantification using RP-HPLC and HPLC-ELSD methodologies.

Methodological Comparison: Direct vs. Indirect Quantification

Core Principles and Limitations

Table 1: Comparison of Indirect and Direct Quantification Approaches

| Feature | Indirect Quantification | Direct Quantification |

|---|---|---|

| Basic Principle | Measures free unencapsulated protein after separation; encapsulation calculated by subtraction from initial amount [23] | Directly measures protein entrapped within liposomes after separation and disruption of vesicles [23] |

| Key Assumptions | Assumes mass balance is achieved; all protein not measured is encapsulated [23] | Makes no mass balance assumptions; measures actual encapsulated content |

| Accuracy Concerns | Potential for inaccurate results due to protein adsorption to surfaces, incomplete separation, or mass balance failures [23] | More accurate representation of actual encapsulation, minimal systematic error |

| Experimental Complexity | Technically simpler but requires careful validation of separation efficiency | Additional steps for liposome disruption but more reliable results |

| Suitable Methods | BCA assay, RP-HPLC of free fraction [23] | BCA assay with solubilisation, RP-HPLC with solubilisation, HPLC-ELSD [23] |

Quantitative Comparison of Protein Quantification Methods

Table 2: Performance Characteristics of Direct Quantification Methods for Protein-Loaded Liposomes

| Quantification Method | Detection Mechanism | Linear Range & Correlation | Limit of Quantification (LOQ) | Key Advantages | Key Limitations |

|---|---|---|---|---|---|

| BCA Assay (with solubilisation) | Reduction of Cu²⁺ to Cu⁺ by peptide bonds under alkaline conditions; colorimetric detection at 562 nm [23] [26] | Linear response with R² > 0.99 [23] | <10 µg/mL [23] | High throughput capability, established protocol, sensitive [23] [26] | Potential interference from lipids and reducing agents [23] [26] |

| RP-HPLC (with solubilisation) | Separation by hydrophobic interactions with C18 column; UV detection at 280 nm [23] [27] | Linear response with R² > 0.99 [23] | <10 µg/mL [23] | High specificity, separates protein from potential contaminants [23] | Requires chromophore for detection; method development needed for different proteins [27] |

| HPLC-ELSD | Evaporative light scattering detection after chromatographic separation [23] | Linear response with R² > 0.99 [23] | <10 µg/mL [23] | Universal detection independent of chromophores, suitable for impurity analysis [23] | Destructive method; requires volatile mobile phases [23] |

Experimental Protocols for Direct Quantification

Liposome Preparation and Sample Processing

Microfluidic Manufacturing of Protein-Loaded Liposomes

- Lipid Composition: Prepare lipid mixtures dissolved in methanol at concentrations ranging from 0.1-4 mg/mL total lipid. For anionic liposomes optimized for protein encapsulation, use formulations containing 50 mol% anionic lipids (e.g., DMPG) with helper lipids [28].

- Aqueous Phase: Prepare protein solution in appropriate buffer (PBS, pH 7.3 ± 0.2 or TRIS, pH 7.4). For enhanced encapsulation with anionic lipids, use acidic buffers (e.g., pH 5.5 acetate buffer) to increase protein cationic character [28].

- Microfluidic Assembly: Utilize a microfluidic herringbone mixer (e.g., Nanoassemblr Benchtop system). Inject lipid phase through one inlet and aqueous protein phase through the second inlet. Use flow rate ratio (FRR) of 3:1 for neutral and anionic formulations, 1:1 for cationic formulations. Total flow rates (TFR) between 10-15 mL/min are typically effective [23].

- Purification: Remove unencapsulated protein using dialysis, size exclusion chromatography, or centrifugation [23] [29].

- Sample Preparation for Direct Quantification: Solubilize purified liposomes using appropriate detergents or solvents to release encapsulated protein. Validate solubilization efficiency to ensure complete protein release [23].

Alternative Method: Lipid Film Hydration with Freeze-Thaw

- Lipid Film Formation: Dissolve lipids in organic solvent (e.g., chloroform), dry under vacuum to form thin lipid film [29].

- Hydration: Hydrate with protein solution in buffer (e.g., 25 mM MOPS, pH 7) [29].

- Freeze-Thaw Cycles: Subject to multiple freeze-thaw cycles (typically 10 cycles) to enhance encapsulation efficiency [29].

- Extrusion: Extrude through polycarbonate filters (e.g., 200 nm) to achieve uniform size distribution [29].

Direct Quantification Protocols

RP-HPLC Method for Direct Protein Quantification

- Equipment: HPLC system with UV detection (e.g., Hewlitt Packard 1100 Series) [23].

- Column: C18 column (150 × 4.6 mm, 300 Å pore size) [23].

- Mobile Phase: Solvent A: 0.1% TFA in water; Solvent B: 100% methanol [23].

- Gradient Program:

- 0-10 min: 100:0 (A:B)

- 10.1 min: 0:100 (A:B)

- 15.1-20 min: 100:0 (A:B) [23]

- Flow Rate: 1 mL/min [23].

- Detection: UV at 280 nm [23].

- Injection Volume: 20 µL [23].

- Calibration: Prepare standard curve with known concentrations of the target protein (e.g., ovalbumin) in the range of 0-500 µg/mL [27].

HPLC-ELSD Method for Direct Protein Quantification

- Equipment: HPLC system coupled with evaporative light scattering detector (e.g., SEDEX 90LT) [23].

- Column: Jupiter A100 column or similar [23].

- Mobile Phase: Use volatile buffers appropriate for the protein of interest.

- Flow Rate: 1 mL/min [23].

- ELSD Settings: Gain of 8; optimal drift tube temperature and gas flow rate established for specific protein [23].

- Calibration: Prepare standard curve with known protein concentrations; typical retention time for ovalbumin is 11.8 min [23].

Micro BCA Assay for Direct Quantification

- Reagents: Commercial Micro BCA protein assay kit [23].

- Procedure:

- Calibration: Prepare standard curve with BSA or target protein in the range of 0-500 µg/mL [27].

Diagram 1: Workflow comparison of indirect versus direct quantification methods for protein encapsulation in liposomes.

Factors Influencing Encapsulation Efficiency and Quantification Accuracy

Formulation Parameters Affecting Encapsulation

- Lipid Composition and Charge: Anionic lipids (e.g., DMPG, phosphatidylserine) can enhance encapsulation efficiency of proteins (up to 70-90% EE) by interacting with cationic surface residues on proteins at acidic pH [28]. Cationic lipids (e.g., DOTAP) also facilitate encapsulation through electrostatic interactions [23].

- Lipid Concentration: Increasing lipid concentration generally increases encapsulation efficiency, with linear relationships observed between lipid concentration and encapsulation for some systems [29].

- Buffer Composition: Ionic strength significantly impacts encapsulation; increasing salt concentration reduces encapsulation efficiency by screening electrostatic interactions between proteins and lipid surfaces [29]. Buffer pH affects protein charge state and interaction with lipids [28].

- Manufacturing Method: Microfluidic mixing typically provides higher encapsulation efficiency and reproducibility compared to traditional methods like thin film hydration [23] [28]. Freeze-thaw cycles during lipid film hydration can increase encapsulation (up to 40% EE reported) [29].

Analytical Considerations for Accurate Quantification

- Separation Efficiency: Complete separation of free from encapsulated protein is critical for both indirect and direct methods. Incomplete separation leads to significant quantification errors [23].

- Solubilization Efficiency: For direct methods, complete disruption of liposomes without protein degradation is essential. Validate solubilization using appropriate detergents or solvents [23].

- Assay Interferences: Lipid components can interfere with colorimetric assays like BCA [23]. HPLC methods with appropriate separation can overcome these interferences [23] [27].

- Protein-to-Protein Variability: Different proteins exhibit varying responses in quantification assays due to differences in amino acid composition [26] [30]. Bradford assay is particularly sensitive to arginine content [26].

The Scientist's Toolkit: Essential Research Reagents and Materials

Table 3: Key Research Reagent Solutions for Liposomal Protein Encapsulation Studies

| Reagent/Material | Function/Application | Examples/Specifications |

|---|---|---|

| Phospholipids | Structural components of liposome bilayers | DSPC (neutral), DMPG (anionic), DOTAP (cationic), Brain PS (anionic) [23] [28] |

| Microfluidic Device | Controlled manufacturing of liposomes | Herringbone micromixer chip (e.g., Nanoassemblr system) [23] |

| Chromatography Columns | Separation for HPLC-based quantification | C18 column (150 × 4.6 mm, 300 Å pore size) [23] |

| Protein Assay Kits | Colorimetric protein quantification | Micro BCA Protein Assay Kit [23] |

| Separation Materials | Purification of liposomes from free protein | Dialysis membranes, size exclusion columns, centrifugal filters [23] [29] |

| Model Proteins | Standard proteins for method development | Ovalbumin (OVA), Bovine Serum Albumin (BSA) [23] [29] |

Direct quantification methods for protein encapsulation in liposomes provide more reliable and accurate results compared to traditional indirect approaches. Based on comparative analysis:

- For routine analysis: The BCA assay with prior liposome solubilization offers a balance of throughput, sensitivity, and accessibility, though potential lipid interference should be validated.

- For highest accuracy: RP-HPLC provides excellent specificity and sensitivity, particularly when method conditions are optimized for the target protein.

- For proteins lacking chromophores: HPLC-ELSD serves as a valuable alternative with universal detection capabilities.

Microfluidic manufacturing combined with anionic lipid formulations represents a promising approach for achieving high encapsulation efficiencies (70-90%) for therapeutic proteins. The protocols detailed herein provide robust methodologies for accurately quantifying these encapsulation efficiencies, supporting the development of advanced liposomal protein delivery systems.

Diagram 2: Decision framework for selecting appropriate protein quantification methods in liposome research.

The quantification of proteins and their encapsulation within delivery systems, such as liposomes, is a critical analytical challenge in pharmaceutical and biopharmaceutical research. This application note details the systematic development and optimization of a Reversed-Phase High-Performance Liquid Chromatography (RP-HPLC) method, contextualized within a broader thesis comparing RP-HPLC and HPLC coupled with an Evaporative Light Scattering Detector (HPLC-ELSD) for protein quantification. The guidelines presented herein are designed to aid researchers and drug development professionals in establishing robust, reliable, and efficient analytical methods.

Theoretical Background and Key Considerations

Reversed-Phase HPLC separates analytes based on their hydrophobicity. The core principle involves the partitioning of analytes between a polar, aqueous mobile phase and a non-polar stationary phase. In protein analysis, gradients are almost universally employed to elute proteins and peptides, which are typically retained strongly on reversed-phase columns. The organic modifier progressively disrupts the hydrophobic interactions between the analyte and the stationary phase, enabling separation based on subtle differences in hydrophobicity.

The choice of detector is paramount, especially for analytes like proteins and lipids that may lack strong chromophores. While UV detection is common, the Evaporative Light Scattering Detector (ELSD) is a valuable tool for detecting non-volatile analytes irrespective of their optical properties [23]. It operates by nebulizing the column effluent, evaporating the volatile mobile phase, and detecting the remaining non-volatile analyte particles via light scattering [15]. This makes it particularly suitable for direct quantification in applications where UV detection is suboptimal.

Method Development Workflow

A systematic approach to method development ensures robustness and efficiency. The workflow can be conceptualized as a series of interdependent decisions, as outlined below.

Diagram 1: Method development workflow for RP-HPLC.

Stationary Phase and Column Selection

The selection of an appropriate column is the foundational step in method development. Key parameters include the base particle, pore size, ligand chemistry, and column dimensions.

- Pore Size: For proteins and large peptides, a wide pore size (300 Å) is recommended to allow full access to the porous structure and sufficient surface area for interaction [31]. For smaller peptides, a 100 Å pore size is typically adequate [9] [23].

- Ligand Chemistry: C18 phases are the workhorse for most small molecules and many peptides [32] [31]. For larger proteins, C8, C4, or wide-pore C18 columns are preferred to prevent overly strong retention and potential denaturation [32].

- Particle Size and Column Dimensions: Smaller particles (e.g., 1.8–3.5 µm) offer higher efficiency and resolution but require systems capable of withstanding higher backpressures. For faster analysis, shorter columns (e.g., 50–150 mm) are employed, while longer columns (e.g., 150–250 mm) provide higher resolution for complex mixtures [31].

Table 1: Guide to HPLC column selection based on analyte properties.

| Analyte Characteristic | Recommended Column Type | Examples |

|---|---|---|

| Small Molecules & Peptides (< 1,000 Da) | Reversed-phase (e.g., C18), 100 Å pores [31] | Pharmaceuticals, small peptides [9] |

| Large Proteins (> 1,000 Da) | Reversed-phase with wide pores (e.g., 300 Å), C4 or C8 ligands [31] | Ovalbumin, Albumin [23] |

| Polar Compounds | HILIC (Hydrophilic Interaction Chromatography) [31] | Carbohydrates, amino acids |

Mobile Phase and Gradient Optimization

The mobile phase composition and gradient profile are critical for achieving optimal separation.

- Mobile Phase Components: The typical mobile phase system consists of water (aqueous component) and a water-miscible organic solvent (organic modifier). Acetonitrile and methanol are the most common modifiers [9] [23]. The choice influences selectivity, viscosity, and UV background.

- Acid Modifiers: Ionizable compounds, such as proteins and peptides, require control of the mobile phase pH to suppress ionization and improve peak shape. Trifluoroacetic acid (TFA) at concentrations of 0.05–0.1% (v/v) is widely used as it provides excellent ion-pairing capabilities and low UV cut-off [9] [23]. Alternative volatile buffers like ammonium acetate or ammonium formate are preferred for mass spectrometry compatibility [33].

- Gradient Elution: A linear or multi-segment gradient is standard for separating mixtures with a wide range of hydrophobicities, such as protein digests or lipid mixtures. The gradient slope (rate of change of organic solvent per unit time) can be optimized to balance resolution and analysis time. For instance, a fast separation of 7 lipids was achieved in 8 minutes using a step gradient [9], while a protein analysis used a 20-minute linear gradient [23].

Detector Selection and Configuration

- UV/Diode Array Detector (DAD): The most common detector, suitable for proteins and peptides containing chromophoric amino acids (e.g., detection of Ovalbumin at 280 nm [23]).

- Evaporative Light Scattering Detector (ELSD): An excellent alternative for analytes lacking a chromophore. The ELSD nebulizes the column effluent into a gas stream, evaporates the volatile mobile phase, and detects the remaining non-volatile analyte particles by light scattering [9] [23]. It is compatible with gradient elution. When using ELSD, mobile phases must be volatile (e.g., TFA, ammonium acetate/formate) and the gas flow and evaporation temperature require optimization for maximum signal-to-noise [9] [15].

Experimental Protocols

Protocol 1: RP-HPLC-UV for Protein Quantification in Liposomes

This protocol is adapted from methods used for the direct quantification of ovalbumin in liposomal formulations [23].

Research Reagent Solutions

| Item | Function/Description |

|---|---|

| C18 Column (e.g., 150 x 4.6 mm, 5 µm, 300 Å) | Stationary phase for separation based on hydrophobicity. |

| Trifluoroacetic Acid (TFA) | Ion-pairing reagent to improve peak shape of proteins/peptides. |

| HPLC-grade Methanol | Organic modifier for the mobile phase. |

| HPLC-grade Water | Aqueous component of the mobile phase. |

| Ovalbumin Standard | Model protein for calibration and quantification. |

Procedure:

- Mobile Phase Preparation: Prepare solvent A: 0.1% (v/v) TFA in water. Prepare solvent B: 0.1% (v/v) TFA in methanol. Filter and degas all solvents.

- Column Equilibration: Install a suitable C18 column (e.g., 150 x 4.6 mm, 5 µm) and equilibrate with 100% solvent A at a flow rate of 1.0 mL/min for at least 10-15 column volumes.

- Chromatographic Conditions:

- Flow Rate: 1.0 mL/min

- Column Temperature: Ambient (or 30°C if controlled)

- Detection: UV at 280 nm

- Injection Volume: 20 µL

- Gradient Program:

- 0-10 min: 100% A → 0% A (linear gradient)

- 10.1-15 min: Hold at 100% B

- 15.1-20 min: Re-equilibrate at 100% A [23]

- Sample Preparation: Dissolve or dilute liposomal formulations in a compatible solvent (e.g., ethanol or the initial mobile phase) to disrupt the vesicles and release the protein for analysis [9] [23].

- System Suitability and Calibration: Inject a series of standard solutions of the target protein (e.g., ovalbumin) to establish a calibration curve before analyzing unknown samples.

Protocol 2: RP-HPLC-ELSD for Lipid Analysis in Nanoparticles

This protocol summarizes a validated method for the simultaneous quantification of multiple lipid components in nanoparticle formulations [9].

Procedure:

- Mobile Phase Preparation: Prepare water and methanol, both containing 0.1% (v/v) TFA. Filter and degas.

- Column Equilibration: Install a Poroshell C18 column (or equivalent) and equilibrate at 50°C.

- Chromatographic Conditions:

- Column Temperature: 50°C

- Mobile Phase: Water (+0.1% TFA) and Methanol (+0.1% TFA)

- Elution: Step gradient (specific proportions optimized for the 7 lipids)

- Analysis Time: 8 minutes

- Detection: ELSD [9]

- ELSD Configuration: Optimize the ELSD parameters according to the manufacturer's guidelines. Typical critical parameters include the nebulizer gas flow rate (e.g., nitrogen) and the evaporator tube temperature.

- Sample Preparation: Dilute the lipid nanoparticle formulation in ethanol to a concentration within the linear range of the detector and calibration curve [9].

The experimental workflow for these protocols is summarized in the diagram below.

Diagram 2: Experimental workflow for RP-HPLC analysis of proteins/lipids.

Application Data and Results

The developed methods have been successfully applied to real-world analyses, demonstrating their robustness.

Table 2: Representative validation data for RP-HPLC methods from literature.

| Validation Parameter | Reported Performance (Lipid Analysis by HPLC-ELSD) [9] | Reported Performance (Protein Analysis Context) [23] |

|---|---|---|

| Linearity (R²) | ≥ 0.997 | 0.99 |

| Precision (RSD) | < 5% (Intermediate Repeatability) | Not specified |

| Accuracy (Recovery) | 92.9% - 108.5% | Not specified |

| Limit of Quantification (LOQ) | 0.04 - 0.10 µg | < 10 µg/mL |

| Analysis Time | 8 minutes for 7 lipids | 20 minutes for protein |

Discussion

The data underscores the capability of well-optimized RP-HPLC methods, whether with UV or ELSD detection, to provide rapid, precise, and accurate quantification of biomolecules in complex formulations. The choice between detectors is application-dependent: UV is straightforward for chromophoric proteins, while ELSD is indispensable for lipids and other molecules without a UV chromophore [9] [23].

When compared to indirect quantification methods (e.g., measuring unencapsulated drug), the direct analysis protocol described here provides a more accurate representation of encapsulation efficiency, as it avoids assumptions of mass balance [23]. The use of AQbD principles and risk assessment in method development, as highlighted in modern literature, further enhances method robustness and ensures compliance with regulatory guidelines [34] [33].

Sample Preparation Techniques for Liposomal and Lipid Nanoparticle (LNP) Formulations

Liposomal and Lipid Nanoparticle (LNP) formulations represent a cornerstone of modern drug delivery systems, enabling the targeted and efficient transport of therapeutic agents from small molecules to large nucleic acids [35] [36]. Their significance in nanomedicine stems from their high biocompatibility, biodegradability, and ability to encapsulate both hydrophilic and hydrophobic compounds [37]. For researchers engaged in comparative studies of analytical techniques like RP-HPLC versus HPLC-ELSD for protein quantification, consistent and reproducible preparation of these lipid-based nanocarriers is paramount. The analytical data's reliability is intrinsically linked to the quality and uniformity of the underlying formulations. This document provides detailed application notes and standardized protocols for preparing liposomes and LNPs, with a specific focus on supporting robust quantitative analysis.

Structural Classification of Lipid-Based Nanocarriers

Lipid-based nanocarriers are primarily classified by their size and lamellarity, which directly influence their drug delivery performance and analytical characteristics [38] [37]. The following diagram illustrates the structural relationships and common preparation methods for different types of vesicles.

Diagram 1: Structural classification of lipid-based nanocarriers, highlighting key differences between liposome types and LNPs.

The structural properties of these nanocarriers are controlled by several critical factors. Size is a primary determinant of biological behavior, with particles between 50-100 nm exhibiting longer circulation times, while those in the 100-150 nm range favor cellular uptake [37]. Lamellarity—whether the vesicle has one (unilamellar) or multiple (multilamellar) bilayer membranes—affects the encapsulated volume and drug release kinetics [38] [37]. Furthermore, the fluidity or rigidity of the lipid bilayer, governed by the lipid composition and phase transition temperature (Tm), directly influences drug permeation and release rates [37].

Critical Preparation Techniques

Common Liposome Preparation Methods

The choice of preparation method significantly impacts key attributes such as size, lamellarity, and encapsulation efficiency, all of which are critical for generating reproducible samples for analytical comparison.

Table 1: Comparison of Common Liposome Preparation Methods

| Method | Key Principle | Vesicle Type | Advantages | Limitations | Suitability for Analysis |

|---|---|---|---|---|---|

| Thin-Film Hydration [38] [37] | Lipid dissolution in organic solvent, evaporation to form thin film, hydration with aqueous buffer | MLVs (can be processed into SUVs/LUVs) | High reproducibility; suitable for small quantities of lipids; relatively simple setup | Low encapsulation efficiency for hydrophilic compounds; requires post-formation processing for uniform size | Excellent for basic membrane interaction studies; requires extrusion/sonication for size-homogeneity sensitive techniques |

| Proliposome Method [38] | Creation of a dry, free-flowing powder mixture of lipids and water-soluble carrier | MLVs, LUVs | Simplicity; good stability of proliposome precursor | Poor reproducibility for small-scale preparations; carrier may interfere with some analyses | Useful for rapid preparation where absolute size control is not critical |

| Extrusion [38] | Forcing MLV dispersions through defined polycarbonate membranes under pressure | SUVs, LUVs | Produces vesicles of well-defined, uniform size; simple and rapid process | Potential lipid loss on membranes; high pressure may degrade sensitive cargo | Highly suitable for preparing samples for HPLC analysis where uniform particle size is critical |

| Sonication [38] | Application of sound energy (via bath or tip) to disrupt and resize MLVs | SUVs | Rapid reduction in particle size; no specialized equipment needed for bath sonication | Potential metal contamination (tip sonication); lipid degradation due to heating; heterogeneous size distribution | Can be used for quick size reduction; requires careful optimization and post-sonication purification for reliable analytics |

Detailed Protocol: Thin-Film Hydration Method for Basic Liposomes

This is one of the most widely used and reproducible methods for preparing multilamellar vesicles (MLVs) [38].

Research Reagent Solutions:

- Lipids: 1,2-dipalmitoyl-sn-glycero-3-phosphocholine (DPPC) or 1-palmitoyl-2-oleoyl-sn-glycero-3-phosphocholine (POPC).

- Solvent: Chloroform/Methanol mixture (3:7, v/v).

- Hydration Buffer: Aqueous buffer (e.g., Phosphate Buffered Saline, PBS, pH 7.4) or purified water.

Procedure:

- Lipid Dissolution: Weigh 2–20 mg of total lipid into a pre-weighed round-bottom flask. Dissolve the lipids in 2–4 mL of the chloroform/methanol mixture.

- Thin Film Formation: Attach the flask to a rotary evaporator. Evaporate the organic solvent at a reduced pressure (200–300 mbar) in a water bath heated to 35–45°C. Rotate the flask to ensure a uniform thin lipid film forms on the inner wall.

- Drying: Further dry the film under high vacuum (5–10 mbar) for at least 4 hours or overnight to remove all traces of organic solvent.

- Hydration: Pre-heat the hydration buffer and the flask containing the thin film above the phase transition temperature (Tm) of the lipids (e.g., 50°C for DPPC, which has a Tm of ~41°C). Add the buffer to the flask to achieve a final lipid concentration of 0.5–10 mg/mL. Hydrate for 45 minutes with occasional vigorous shaking and brief sonication (≈30 s) in a water bath sonicator. The film will peel off and form multilamellar vesicles (MLVs).

- Post-Processing (Optional): To form Small or Large Unilamellar Vesicles (SUVs/LUVs), subject the MLV suspension to extrusion through polycarbonate membranes of defined pore size (e.g., 50 nm, 100 nm) using a liposome extruder, or to sonication as described in Table 1.

- Storage: Store the final liposome dispersion in sealed vials under an inert atmosphere (e.g., nitrogen) at 4°C. For long-term storage, freeze in liquid nitrogen and store at -80°C [38].

Detailed Protocol: Preparation of MC3-LNPs for RNA Delivery

This protocol details the formation of ionizable lipid nanoparticles (LNPs) specifically designed for encapsulating nucleic acids, such as mRNA or siRNA, using the scalable pipette mixing method [39].

Research Reagent Solutions:

- Lipid Mix: DLin-MC3-DMA (ionizable lipid), DSPC (phospholipid), Cholesterol, DMG-PEG 2000 (PEGylated lipid) at a molar ratio of 50:10:38.5:1.5.

- Solvent: Absolute ethanol.

- Aqueous Buffer: 10 mM Citrate Buffer, pH 4.

- Payload: RNA stock solution (1 mg/mL in citrate buffer).

- Dialysis Buffer: 1x PBS, pH 7.4.

Procedure:

- Lipid Solution Preparation: Dissolve the individual lipid components in ethanol to make stock solutions. Combine them in a glass vial to form the "lipid mix" at the specified molar ratio. The final concentration should be approximately 19 μg of total lipid per μL of ethanol.

- Aqueous RNA Solution Preparation: In a separate RNase-free tube, dilute the RNA stock solution in 10 mM citrate buffer (pH 4).

- Pipette Mixing:

- Add 16.8 μL of the lipid mix to a tube and add 1.2 μL of ethanol. Mix well.

- Quickly pipette 54 μL of the RNA buffer solution and add it to the lipid solution.

- Pipette the combined mixture up and down rapidly for 20–30 seconds. The LNPs form instantaneously.

- Incubation: Allow the LNP solution to stand at room temperature for 15 minutes.

- Buffer Exchange and Purification: Transfer the LNP solution to a dialysis device (MWCO 3.5 kDa) and dialyze against a large volume of 1x PBS (pH 7.4) for at least 1 hour to remove ethanol, adjust the pH to physiological conditions, and remove unencapsulated RNA.

- Final Formulation: After dialysis, recover the LNP suspension and adjust the final volume to 800 μL with 1x PBS [39].

The following workflow summarizes the key decision points and steps in LNP preparation.

Diagram 2: A generalized workflow for the preparation and quality control of liposomes and LNPs, culminating in analytical quantification.

The Scientist's Toolkit: Essential Materials

Successful formulation and analysis require a set of core reagents and analytical tools.

Table 2: Essential Research Reagent Solutions for LNP Formulation and Analysis

| Category | Component | Typical Function | Example in Protocol |

|---|---|---|---|

| Structural Lipids | Phosphatidylcholines (e.g., DPPC, DSPC, POPC) | Forms the primary bilayer structure; provides mechanical integrity [37]. | DPPC in thin-film hydration [38]. |

| Ionizable/Cationic Lipids | DLin-MC3-DMA, DODMA | Enables nucleic acid complexation and endosomal escape in LNPs [39] [9]. | DLin-MC3-DMA in MC3-LNP protocol [39]. |

| Stability Modifiers | Cholesterol | Modulates membrane fluidity and stability; enhances in vivo performance [35] [39]. | Component in MC3-LNP and clinical formulations [39]. |

| Stealth/Steric Stabilizers | DMG-PEG 2000, DSPE-PEG2000 | Prevents nanoparticle aggregation and opsonization; prolongs circulation time [35] [39]. | DMG-PEG 2000 in MC3-LNP protocol [39]. |

| Analytical Standards | Individual lipid standards | Essential for calibrating analytical instruments like HPLC-ELSD for accurate quantification [9]. | DSPC, Cholesterol, DOPE standards for HPLC [9]. |

| Critical Solvents & Buffers | Chloroform/Methanol, Ethanol, Citrate Buffer, PBS | Solubilizes lipids during formulation; provides controlled pH environment for self-assembly and stability [38] [39]. | Ethanol for lipid dissolve, Citrate pH 4 for RNA-LNP formation [39]. |

Analytical Considerations for HPLC-ELSD Analysis

The preparation protocols directly impact the subsequent analysis using techniques like Reversed-Phase High-Performance Liquid Chromatography with Evaporative Light Scattering Detection (HPLC-ELSD). HPLC-ELSD is particularly valuable for quantifying lipids that lack chromophores, making it ideal for monitoring lipid composition in nanoparticle formulations [9] [40].

For reliable HPLC-ELSD results, sample preparation is key. Liposome or LNP formulations can be simply diluted in a compatible solvent like ethanol to dissolve the particles and release the lipid components for analysis [9]. This direct quantification is crucial for determining critical quality attributes such as lipid encapsulation efficiency, final formulation composition, and batch-to-batch consistency [24] [9]. The robustness of ELSD, with its compatibility with gradient elution and relative insensitivity to the mobile phase, makes it a suitable detector for the quality control of these complex nanomedicines [9].

Simultaneous Analysis of Proteins and Excipients in a Single Run

In the development of complex biopharmaceuticals, such as protein-loaded liposomes and peptide therapeutics, a significant analytical challenge exists: the need for separate methods to quantify the active pharmaceutical ingredient (API) and formulation excipients. Traditional reversed-phase high-performance liquid chromatography (RP-HPLC) with UV detection is often insufficient for this task, as many critical excipients lack chromophores [9] [7]. This application note details a robust analytical strategy based on hydrophilic interaction liquid chromatography (HILIC) coupled with diode array and evaporative light scattering detectors (HPLC-DAD/ELSD) to simultaneously analyze proteins and excipients within a single chromatographic run. This approach is framed within broader research comparing RP-HPLC and HPLC-ELSD for protein quantification, highlighting the advantages of the latter for comprehensive formulation characterization.

The Analytical Challenge

Limitations of Conventional Techniques

Traditional analytical workflows for complex formulations typically require multiple, separate methods:

- RP-HPLC-UV effectively detects proteins and peptides with chromophores but fails to detect non-chromophoric excipients like phosphate ions, sugars, and many lipids [7].

- Indirect quantification of protein encapsulation in delivery systems (e.g., by measuring free, unencapsulated protein) is common but can be inaccurate, as it assumes perfect mass balance [23].

- Standalone techniques for excipient analysis (e.g., ion chromatography, ICP-MS) increase analysis time, cost, and sample volume requirements [12].

The Need for a Unified Approach

Simultaneous analysis provides a more complete picture of the final pharmaceutical product. It allows for:

- Direct quantification of protein encapsulation efficiency [23].

- Comprehensive profiling of impurities stemming from both the API and the formulation process [7].

- Real-time monitoring of critical quality attributes during formulation development and quality control.

Solution: HILIC-DAD-ELSD for Simultaneous Analysis

Orthogonal Detection: DAD and ELSD

The combination of DAD and ELSD detectors overcomes the limitation of detecting only chromophoric compounds.

- DAD (Diode Array Detector): Ideal for detecting proteins, peptides, and other compounds with UV-active functional groups [7].

- ELSD (Evaporative Light Scattering Detector): A universal detector for non-volatile and semi-volatile analytes, regardless of their optical properties. It operates by nebulizing the column effluent, evaporating the mobile phase, and detecting the remaining analyte particles via light scattering [9] [12] [7]. This makes it perfectly suited for detecting lipids, sugars, and inorganic ions that are common as excipients.

Chromatographic Mode: Hydrophilic Interaction Liquid Chromatography (HILIC)

For simultaneous analysis of hydrophilic excipients and hydrophobic proteins, HILIC offers significant advantages over RP-HPLC.

- Retention of Polar Compounds: HILIC provides enhanced retention for polar compounds that are poorly retained in RP-HPLC, such as ionic excipients [41] [7].

- Orthogonal Separation Mechanism: The HILIC separation mechanism, which involves partitioning into a water-enriched layer on a hydrophilic stationary phase, is orthogonal to RP-HPLC, offering different selectivity [41].