Optimizing Protein Concentration Measurement: A Guide to Enhanced Accuracy for Reliable Research and Development

Accurate protein quantification is a foundational pillar of research and drug development, yet it is challenged by the lack of a universal gold standard and numerous potential interferences.

Optimizing Protein Concentration Measurement: A Guide to Enhanced Accuracy for Reliable Research and Development

Abstract

Accurate protein quantification is a foundational pillar of research and drug development, yet it is challenged by the lack of a universal gold standard and numerous potential interferences. This article provides a comprehensive guide for researchers and scientists to navigate these challenges. It covers the core principles of protein assays, the strategic selection of methodologies for different applications, advanced troubleshooting and optimization techniques to overcome common pitfalls, and the rigorous validation required for regulatory compliance. By synthesizing current technologies and best practices, this resource aims to empower professionals to generate more precise, reproducible, and reliable protein data, thereby strengthening downstream analyses and conclusions.

The Foundation of Protein Quantification: Principles, Challenges, and the Quest for a Gold Standard

Why There Is No Universal Gold Standard for Protein Quantification

Protein quantification is a fundamental requirement in biological research and biopharmaceutical development, crucial for everything from drug discovery to release testing of final drug products [1]. Despite its importance, a single, universal "gold standard" method for accurately quantifying all proteins in every situation does not exist. This article explores the technical reasons behind this challenge and provides a structured guide to help researchers select and validate the most appropriate method for their specific needs.

FAQ: Understanding the Core Challenge

Why is there no single method that works for all proteins?

The immense structural diversity of proteins is the primary reason no single quantification method works universally. This variety leads to significant differences in physicochemical properties and microheterogeneity, which hinders universal quantification [1]. Proteins can differ in:

- Amino Acid Composition: Colorimetric assays (e.g., BCA, Bradford) rely on reactions with specific amino acids. Proteins with low proportions of these amino acids will yield inaccurate concentration estimates [2] [3].

- Size and Complexity: Large transmembrane proteins, for example, pose unique challenges as they are embedded in lipid membranes, making them less accessible to dyes and reagents [3].

- Post-Translational Modifications: Modifications like phosphorylation or glycosylation can alter a protein's structure and affect how it interacts with assay reagents or antibodies [4].

- Sample Matrix: Buffer components, detergents, reducing agents, and other molecules in the sample can interfere with many assay chemistries, leading to over- or under-estimation of concentration [1] [2].

What are the main limitations of common protein quantification methods?

The table below summarizes the pros and cons of widely used techniques, highlighting why their utility is context-dependent.

Table 1: Comparison of Common Protein Quantification Assays

| Assay Method | Principle | Pros | Cons | Best For |

|---|---|---|---|---|

| BCA Assay [2] | Colorimetric; reduction of Cu²⁺ by protein in an alkaline environment. | Compatible with many detergents; wide dynamic range; reasonably high throughput. | Susceptible to interference from reducing agents and metal chelators; relies on specific amino acids (Tyr, Trp, Cys). | General lab use with compatible buffers; determining total protein content in partially purified samples. |

| Bradford Assay [2] | Colorimetric; shift in absorbance of Coomassie dye upon binding to protein. | Rapid, one-step protocol; not affected by reducing agents. | Highly susceptible to interference from detergents (SDS, Triton) and buffer components (Tris, EDTA); relies on specific amino acids (Arg, Lys, Tyr). | Quick estimates of total protein in simple, detergent-free solutions. |

| UV Absorbance (A280) [2] | Measures absorbance of ultraviolet light by aromatic amino acids. | Quick and easy; no reagents or incubation; requires very low sample volume. | High interference from nucleic acids and common buffer components; low sensitivity; relies on aromatic amino acids. | Purified protein samples where the extinction coefficient is known and contaminants are absent. |

| ELISA [5] [2] | Immunoassay using antibody-antigen binding for specific detection. | High sensitivity and specificity; high throughput; works in complex samples. | Time-consuming optimization; longer assay time; higher cost; requires specific antibodies; provides semi-quantitative data unless carefully validated. | Quantifying a specific target protein in a complex mixture like serum or cell lysate. |

| Western Blot [5] [6] | Immunodetection after protein separation by electrophoresis. | High specificity; provides information on protein size and modifications; confirms identity. | Semi-quantitative; low throughput; time-consuming; technically complex; less sensitive than ELISA. | Confirming a protein's identity, checking for modifications, and semi-quantitative analysis when sample is limited. |

Troubleshooting Guides

How do I choose the right protein quantification assay?

Selecting the correct assay requires a systematic consideration of your specific protein, sample, and experimental context. The following decision workflow can guide your choice.

My assay results are inconsistent. What could be the cause?

Inconsistent results often stem from sample preparation issues or interference.

Problem: Interfering Substances in Buffer.

- Solution: Review your buffer composition against the assay's known interferents (see Table 1). Dilute the sample if possible, or use a cleanup method like precipitation. Consider switching to a more compatible assay (e.g., from Bradford to BCA if detergents are present) [2].

Problem: Protein Composition Affects Signal.

- Solution: Be aware that colorimetric assays are sensitive to amino acid composition. If your protein is rich or poor in certain amino acids, the concentration will be skewed. Use a standard protein that closely matches your target protein's composition for the calibration curve, or transition to an antibody-based method like ELISA for specific quantification [2] [3].

Problem: Protein Degradation or Instability.

- Solution: Labile proteins and proteases can cause degradation during sample handling. Keep samples on ice, use protease inhibitor cocktails, and minimize freeze-thaw cycles. For problematic samples, deactivate proteases by denaturation (e.g., with urea) if the assay can tolerate it [1].

Detailed Experimental Protocol: Indirect ELISA for Transmembrane Protein Quantification

This protocol is adapted from a study comparing quantification methods for Na, K-ATPase (NKA), a transmembrane protein, where conventional assays overestimated concentration compared to a targeted ELISA [3]. It demonstrates a method to overcome challenges with complex proteins.

Materials and Reagents

Table 2: Research Reagent Solutions for Indirect ELISA

| Item | Function / Description |

|---|---|

| 96-Well Microplate | Solid substrate for binding proteins and antibodies [5]. |

| Coating Buffer | (e.g., Carbonate-Bicarbonate buffer, pH 9.6) Optimizes adsorption of the antigen to the plate. |

| Blocking Buffer | (e.g., 1-5% BSA in PBS-T) Covers uncovered plastic surface to prevent non-specific antibody binding [5]. |

| Target Protein & Standard | The protein to be quantified. A purified standard of known concentration is required for the calibration curve. |

| Primary Antibody | An antibody with high specificity for the target protein [3]. |

| Enzyme-Linked Secondary Antibody | (e.g., HRP-conjugated) Binds to the primary antibody. The enzyme catalyzes the color-producing reaction. |

| Wash Buffer | (e.g., PBS with Tween 20 - PBS-T) Removes unbound antibodies and reagents to reduce background. |

| Enzyme Substrate | (e.g., TMB for HRP) A chromogenic compound that produces a measurable color change when cleaved by the enzyme [5]. |

| Stop Solution | (e.g., Acid) Halts the enzyme-substrate reaction at a defined time. |

| Microplate Reader | Instrument to measure the absorbance of the colored product in each well. |

Step-by-Step Methodology

- Coating: Dilute your protein samples and standards in a suitable coating buffer. Add a known volume (e.g., 100 µL) to each well of a 96-well microplate. Incubate the plate overnight at 4°C or for 1-2 hours at 37°C to allow the protein to adsorb to the well surface.

- Washing: Empty the plate and wash each well 2-3 times with wash buffer (e.g., PBS-Tween) to remove any unbound protein.

- Blocking: Add a blocking buffer (e.g., 1-5% BSA) to each well to cover all uncovered binding sites on the plastic. Incubate for 1-2 hours at room temperature. Wash the plate again as in step 2.

- Primary Antibody Incubation: Add the primary antibody, diluted in blocking buffer, to each well. Incubate for 1-2 hours at room temperature. Wash thoroughly to remove any unbound primary antibody.

- Secondary Antibody Incubation: Add the enzyme-conjugated secondary antibody, diluted in blocking buffer, to each well. Incubate for 1-2 hours at room temperature. Wash thoroughly again.

- Detection: Add the appropriate enzyme substrate to each well. Incubate in the dark for a defined period (typically 15-30 minutes) to allow color development.

- Stop Reaction and Read: Add the stop solution to each well to halt the reaction. Immediately measure the absorbance of the solution in each well using a microplate reader at the appropriate wavelength (e.g., 450 nm for TMB).

- Data Analysis: Generate a standard curve by plotting the absorbance of the standards against their known concentrations. Use the curve to interpolate the concentration of your unknown samples [5] [3].

Validating Your Protein Quantification Assay

For critical applications like drug development, assay validation is essential. Regulatory guidelines (e.g., ICH) require validation of parameters such as [1]:

- Accuracy: How close the measured value is to the true value.

- Precision: The closeness of agreement between a series of measurements (repeatability and intermediate precision).

- Specificity: The ability to assess the analyte unequivocally in the presence of other components.

- Linearity and Range: The interval over which the method provides results with direct proportionality to analyte concentration.

- Detection/Quantification Limit: The lowest amount of analyte that can be detected or quantified with acceptable accuracy and precision.

A risk-based strategy, such as Failure Mode and Effects Analysis (FMEA), can be an efficient approach to identify and control critical parameters in your quantification method [1].

Accurate protein quantification is a cornerstone of research in biochemistry, molecular biology, and drug development. The choice of assay directly impacts the reliability and reproducibility of experimental results, from Western blotting to enzyme kinetics studies. This guide details the core principles, methodologies, and troubleshooting for the four major protein quantification techniques—Bradford, BCA, Lowry, and UV Absorbance—to help optimize measurement accuracy in your research.

Core Principles and Mechanisms

Bradford Assay

The Bradford assay is a rapid, colorimetric method based on the binding of Coomassie Brilliant Blue G-250 dye to proteins. In an acidic environment, the dye shifts from a red-brown form (absorbance maximum at 465 nm) to a blue form (absorbance maximum at 610 nm) upon binding primarily to basic (arginine, lysine, and histidine) and aromatic amino acid residues in proteins [7] [8]. The absorbance of the resulting protein-dye complex is measured at 595 nm, and its intensity is proportional to the protein concentration [9]. The assay is sensitive for proteins larger than 3,000-5,000 Daltons [7] [10].

BCA (Bicinchoninic Acid) Assay

The BCA assay is a two-step reaction involving the reduction of Cu²⁺ to Cu¹⁺ by peptide bonds in an alkaline environment (the biuret reaction). The Cu¹⁺ ions then chelate with two molecules of bicinchoninic acid (BCA) to form a purple-colored complex [11]. The absorbance of this complex is measured at 562 nm and is proportional to the protein concentration. The reduction is also enhanced by the side chains of cysteine, cystine, tyrosine, and tryptophan residues [12].

Lowry Assay

The Lowry assay combines the biuret reaction (where peptide bonds reduce Cu²⁺ to Cu¹⁺ under alkaline conditions) with the subsequent reduction of the Folin-Ciocalteu reagent (phosphomolybdate/phosphotungstic acid) by the copper-treated protein [13] [14]. This second reduction step, primarily catalyzed by tyrosine, tryptophan, and cysteine residues, produces a deep blue-green color, measured at 650-750 nm [13]. This combination makes it more sensitive than the biuret reaction alone.

UV Absorbance at 280 nm

This direct method leverages the innate ultraviolet absorbance of aromatic amino acids, primarily tryptophan and tyrosine, in the protein backbone. The absorbance at 280 nm is measured and related to concentration using the Beer-Lambert law, with the protein's specific extinction coefficient [15]. Note that light scattering from particulates or aggregates can lead to inaccuracies [15].

Comparative Analysis of Protein Assays

The table below provides a quantitative comparison of the four major protein assays to guide method selection.

| Feature | Bradford Assay | BCA Assay | Lowry Assay | UV Absorbance |

|---|---|---|---|---|

| Principle | Dye-binding (Coomassie Blue) | Copper reduction & BCA chelation | Copper reduction & Folin-Ciocalteu | Aromatic amino acid absorbance |

| Detection Wavelength | 595 nm [7] [8] | 562 nm [11] | 650–750 nm [13] [14] | 280 nm [15] |

| Typical Sensitivity Range | 1–1,500 µg/mL [7] | 20–2,000 µg/mL [11] | 5–100 µg/mL [13] | Varies by protein |

| Key Compatible Substances | Buffers, metal ions, reducing agents, chelators [7] | Detergents, reducing agents (low conc.) [11] | - | N/A (sample-dependent) |

| Key Interfering Substances | Detergents [7] [8] | High conc. reducing agents & chelators [12] [11] | Detergents, reducing agents, carbohydrates, EDTA [13] | Nucleic acids, turbidity, buffers with UV absorbance |

| Assay Time | ~10 minutes [7] | 30 min (37°C) – 2 hr (RT) [11] | ~40 minutes [13] [14] | Immediate |

| Protein-to-Protein Variability | High (binds basic/aromatic aa) [7] | Moderate (enhanced by Cys, Tyr, Trp) [11] | Moderate (dependent on Tyr, Trp) [13] | High (dependent on Trp/Tyr content) |

| Cost & Complexity | Low, simple [8] | Moderate [14] | Moderate [14] | Low, no reagents |

Troubleshooting Guides and FAQs

Bradford Assay

Q: My Bradford assay samples show low or no absorbance. What could be wrong?

- Cause: The protein sample may be too dilute, or its molecular weight may be below the 3,000-5,000 Dalton detection limit [10].

- Solution: Concentrate the sample or switch to a more sensitive assay like the BCA for small proteins/peptides [10].

- Cause: The Bradford reagent may be old, improperly stored, or used while too cold [10].

- Solution: Use fresh reagent that has been brought to room temperature before use [10].

Q: A precipitate formed upon adding the Bradford reagent. How can I fix this?

- Cause: Detergents in the protein buffer (e.g., Triton X-100) are a common cause of precipitation [7] [10].

- Solution: Dialyze the sample or dilute it to a point where the detergent no longer interferes. Consider using a detergent-compatible Bradford assay kit [7] [10].

BCA Assay

Q: The color development in my BCA assay is inconsistent.

- Cause: Fluctuations in incubation temperature can directly impact the rate of color development [11].

- Solution: Ensure a consistent and accurate incubation temperature (e.g., 37°C) and protect the plate from temperature gradients [11].

- Cause: Inaccurate pipetting of the working reagent or samples [12].

- Solution: Use calibrated pipettes and reverse pipetting for viscous reagents to improve accuracy.

Q: My BCA standard curve is poor, or I get a "Standards Incorrect" error on my instrument.

- Cause: The kit may have expired, been stored incorrectly, or the BSA standard may be degraded [12].

- Solution: Always prepare fresh calibration standards and replace the kit if components are expired or contaminated [12].

Lowry Assay

Q: The Lowry assay gives inaccurate readings for my protein sample.

- Cause: The sample buffer contains interfering substances like reducing agents (DTT, β-mercaptoethanol), detergents (SDS), or strong alkaline buffers [13] [14].

- Solution: Dialyze or desalt the sample into a compatible buffer. Alternatively, precipitate the protein to remove interfering substances and re-dissolve it [12] [14].

Q: Why do different proteins give different responses in the Lowry assay?

- Cause: The Folin-Ciocalteu reaction depends on the content of tyrosine, tryptophan, and cysteine residues, which varies between proteins [13].

- Solution: For maximum accuracy, use a purified sample of the target protein itself to prepare the standard curve, rather than BSA [12].

UV Absorbance

Q: My protein concentration measured by A280 seems artificially high.

- Cause: Significant interference from nucleic acids, which have a strong absorbance peak at 260 nm [15].

- Solution: Use a correction formula (e.g.,

Protein Concentration (mg/mL) = 1.55*A280 - 0.76*A260) or purify the protein further. - Cause: Light scattering from particulates or protein aggregates in the solution [15].

- Solution: Clarify the sample by centrifugation or filtration before measurement.

Q: The spectrophotometer gives unstable or drifting baseline readings.

- Cause: Aging lamp, insufficient warm-up time, or debris in the light path or cuvette [16].

- Solution: Allow the instrument to warm up for 15-30 minutes, calibrate it regularly, and use clean, scratch-free cuvettes [16].

Detailed Experimental Protocols

Protocol 1: Bradford Assay (Microplate Format)

This protocol is adapted for high-throughput analysis using a microplate reader [7] [8].

Research Reagent Solutions:

| Item | Function |

|---|---|

| Coomassie Dye Reagent | Binds to protein, causing a color shift for detection [8]. |

| Bovine Serum Albumin (BSA) Standard | Provides known protein concentrations to generate a standard curve [8]. |

| Compatible Buffer (e.g., PBS) | Used to dilute the protein standard and unknown samples [8]. |

Procedure:

- Prepare Standard Curve: Serially dilute BSA standard in PBS to create a range of concentrations (e.g., 0, 0.1, 0.2, 0.5, 1.0 mg/mL) [8].

- Prepare Samples: Dilute unknown protein samples in the same buffer as the standards.

- Add Reagents: Pipette 20-150 µL of each standard and unknown sample into a microplate well. Add 1 mL of Bradford reagent to each well and mix thoroughly [8].

- Incubate: Incubate the plate at room temperature for 5-10 minutes [7] [8].

- Measure Absorbance: Read the absorbance at 595 nm using a microplate reader.

- Analyze Data: Plot the standard curve (Absorbance vs. BSA concentration) and use the linear regression equation to calculate the concentration of the unknown samples [8].

Protocol 2: Lowry Assay (Test Tube Format)

This is the classic two-step protocol for the Lowry assay [13] [14].

Research Reagent Solutions:

| Item | Function |

|---|---|

| Lowry Reagent A (Alkaline Copper) | Creates alkaline conditions for the Biuret reaction (Cu²⁺ reduction) [14]. |

| Lowry Reagent B (Folin-Ciocalteu) | Is reduced by the copper-treated protein to produce the final blue color [13]. |

| BSA Standard | Provides known protein concentrations for the standard curve [14]. |

Procedure:

- Prepare Standard Curve: Prepare BSA standards in the range of 0-100 µg/mL [14].

- Add Reagent A: To 1 mL of each standard and unknown sample, add 1 mL of Lowry Reagent A. Mix and incubate for 10 minutes at room temperature [13] [14].

- Add Reagent B: Add 0.1 mL of Lowry Reagent B, mix rapidly and thoroughly immediately after addition. Incubate for 30 minutes in the dark [13] [14].

- Measure Absorbance: Read the absorbance at 750 nm [14].

- Analyze Data: Generate a standard curve and interpolate the unknown sample concentrations.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Reagent / Kit | Primary Function | Key Considerations for Selection |

|---|---|---|

| Bradford Plus Kit with Pre-diluted Standards | Fast, convenient protein quantification with reduced pipetting steps [7]. | Ideal for high-throughput labs; reduces standard preparation errors [7]. |

| Detergent-Compatible Bradford Assay | Quantifies protein in samples containing up to 1% detergents (Triton X-100, NP-40) [7]. | Essential for protein extracts from membrane preparations [7]. |

| BCA Protein Assay Kit | Sensitive, detergent-tolerant quantification via copper reduction [11]. | Preferred over Bradford for samples with detergents or when using plastic cuvettes [11]. |

| Pierce 660 nm Protein Assay | Protein quantification using a dye-metal complex; compatible with most detergents and reducers [7]. | Excellent alternative to Bradford with better linearity and wider detergent compatibility [7]. |

| Folin-Ciocalteu Reagent | Key component for the colorimetric detection step in the Lowry assay [13]. | Light-sensitive and has a limited shelf life once diluted [13]. |

| Ultra-Pure BSA Standard | Provides a highly accurate and consistent protein standard for calibration curves. | Critical for assay accuracy; ensures standard curve reliability across experiments [8]. |

Understanding Key Interfering Substances for Each Assay Type

FAQs: Navigating Common Interference Issues

1. My immunoassay is showing a falsely elevated (or depressed) result for a patient sample, but I suspect this doesn't match the clinical picture. What could be the cause?

This is a classic sign of interference in immunoassays. The issue often stems from endogenous substances in the patient's sample, such as:

- Heterophile antibodies or human anti-animal antibodies that can bind to assay antibodies, interfering with the reaction [17].

- Cross-reacting substances, including structurally similar drugs or their metabolites, which the assay antibody mistakenly recognizes [17].

- Rheumatoid factors (autoantibodies) that can cause similar interference [17].

- Endogenous binding proteins (e.g., hormone binding globulins) that may alter the measurable concentration of the analyte [17].

2. My Bradford assay shows unexpectedly high background or low absorbance. What are the usual suspects?

The Bradford assay is highly sensitive to the composition of your sample buffer. Common interfering substances and their effects are detailed in the table below. Frequently, the culprits are:

- Detergents in your protein buffer, which often cause precipitates or high background [10].

- High alkaline concentrations, which can raise the pH beyond the assay's limits, turning the sample dark blue [10].

- The sample containing a low molecular weight protein below the assay's detection limit (~3,000-5,000 Daltons) [10].

3. I am setting up a digital PCR assay and see positive signals in my No Template Control (NTC). Is this always contamination?

Not necessarily. To determine the cause, examine the mean relative fluorescence unit (RFU) of the positive control samples.

- If the positives in your NTCs have the same fluorescence as your true samples, it is likely contamination [18].

- If the positives are of much lower amplitude, more random, or diffused, it is likely an assay artifact [18]. Proper threshold setting, informed by the NTC's negative population, is crucial to avoid this issue [18].

4. For my Immunoprecipitation (IP) experiment, I get a low or no signal. What should I investigate first?

Begin by troubleshooting your experimental conditions:

- Check your lysis buffer: Stringent lysis conditions (e.g., using RIPA buffer containing ionic detergents like sodium deoxycholate) can disrupt protein-protein interactions in co-IP experiments. Use a milder cell lysis buffer instead [19].

- Confirm protein expression: Verify that your target protein is expressed at detectable levels in your cell line or tissue [19].

- Include essential controls: Always run an input lysate control to confirm the presence of your target protein and the functionality of your antibody [19].

Troubleshooting Guides: Key Interfering Substances by Assay

Protein Quantification Assays

Table 1: Common Interfering Substances in Protein Quantification Assays

| Assay Type | Key Interfering Substances | Maximum Tolerable Concentration (Approx.) | Observed Effect | Recommended Solution |

|---|---|---|---|---|

| Bradford Assay | Detergents (SDS, Triton X-100) [10] | Varies by detergent (e.g., 0.01% SDS) [10] | Precipitation, high background [10] | Dilute sample, dialyze, or use alternative assay [10] |

| Alkaline Buffers [10] | - | Sample turns dark blue [10] | Dilute or dialyze sample [10] | |

| BCA Assay | Reducing Agents (e.g., DTT, β-Mercaptoethanol) [12] | ≤1 mM DTT [1] | Reduction of Cu²⁺, falsely high absorbance [12] | Use BCA Reducing Agent Compatible Assay or dialyze sample [12] |

| Chelators (e.g., EDTA) [12] | ≤10 mM EDTA [1] | Chelation of Cu²⁺, falsely low absorbance [12] | Dilute sample to lower EDTA concentration [12] | |

| Micro BCA Assay | Reducing Agents & Chelators [12] | Similar to BCA | Same as BCA assay | Dilute, dialyze, or precipitate protein [12] |

| 660 nm Assay | Ionic Detergents [12] | - | Altered color response, inaccurate readings [12] | Use a compatible assay (e.g., BCA) or remove detergent [12] |

| Modified Lowry Assay | Detergents, Reducing Agents, Chelators [12] | - | Altered color development | Remove interfering substances via dialysis or precipitation [12] |

Immunoassays (e.g., ELISA, AlphaLISA)

Table 2: Common Interfering Substances in Immunoassays

| Interfering Substance | Assay Type Impacted | Observed Effect | Recommended Solution |

|---|---|---|---|

| Heterophile Antibodies [17] | Sandwich Immunoassays | Falsely elevated or falsely low results [17] | Use blocking agents, alternate assay, or sample pre-treatment [17] |

| Human Anti-Animal Antibodies [17] | Immunoassays using animal antibodies | Falsely elevated or depressed values [17] | Use species-specific blocking reagents or employ alternative methods [17] |

| Cross-reacting Molecules (e.g., metabolites, drugs) [17] | Drug, Hormone, and Tumor Marker assays | Over- or underestimation of analyte [17] | Use a more specific assay (e.g., LC-MS/MS) [17] |

| Lysis Buffer Incompatibility | AlphaLISA SureFire | Reduced or abolished signal [20] | Use kit-specific lysis buffer; RIPA buffer is often incompatible unless diluted [20] |

| High Biotin Levels (in media/serum) [20] | Assays using streptavidin-bead chemistry | High background or suppressed signal [20] | Use biotin-free assay kits or dilute sample [20] |

| High DMSO Concentration [20] | Cell-based assays (e.g., AlphaLISA) | Can affect cell health and signaling | Keep concentrations ≤2% where possible [20] |

Experimental Protocols for Identifying and Overcoming Interference

Protocol 1: Systematic Approach to Detect Immunoassay Interference

When a laboratory result is clinically discordant, follow these steps to investigate potential interference [17]:

- Clinical Flagging: The physician communicates the clinical suspicion to the laboratory. This partnership is essential for identifying problematic results [17].

- Re-testing: Repeat the analysis on the same platform.

- Alternate Method Analysis: Re-measure the analyte using a different immunoassay platform or, ideally, a method based on a different principle (e.g., chromatography).

- Linearity and Dilution Test: Perform serial dilutions of the patient sample with a non-immune serum or assay buffer. A non-linear dilution profile is a strong indicator of interference.

- Blocking Experiments: Pre-incubate the sample with a blocking reagent designed to neutralize heterophile or human anti-animal antibodies (e.g., heterophile blocking tubes). Recovery of the result post-blocking confirms this type of interference [17].

- Ultrafiltration or Precipitation: For small analyte interference, these physical separation techniques can be useful.

Protocol 2: Testing for Substance Interference in Colorimetric Protein Assays

If you suspect your sample buffer is interfering with a Bradford, BCA, or similar assay, use this method to confirm [10]:

- Prepare Two Standard Curves:

- Curve A: Prepare your protein standard (e.g., BSA) dilutions in ultrapure water or a compatible buffer.

- Curve B: Prepare identical protein standard dilutions in your sample's buffer.

- Perform the Assay: Run both standard curves according to your standard protocol.

- Analyze the Data: Plot protein concentration versus absorbance for both curves.

- Interpretation: If the slopes of the two curves are significantly different, the sample buffer is interfering with the assay. If the slopes match, the buffer is not causing interference [10].

- Mitigation: If interference is confirmed, you can:

- Dilute the Sample: If the protein concentration is high enough, dilute the sample to reduce the interferent below its threshold.

- Dialyze or Desalt: Transfer the protein into a compatible buffer.

- Precipitate and Re-dissolve: Use TCA/acetone precipitation to pellet the protein, then dissolve the pellet in a compatible buffer [12].

Visual Guide: Mechanisms of Immunoassay Interference

The following diagram illustrates the primary mechanisms through which substances can interfere with sandwich immunoassays, a common format for protein detection.

The Scientist's Toolkit: Key Reagents for Interference Management

Table 3: Essential Reagents and Materials for Troubleshooting Interference

| Reagent / Material | Function in Troubleshooting | Example Use Case |

|---|---|---|

| Heterophile Blocking Reagents [17] | Neutralizes interfering heterophile and human anti-animal antibodies in patient samples. | Added to serum samples prior to immunoassay analysis to confirm and eliminate antibody-mediated interference. |

| Protein A / G Beads [19] | Binds antibodies for immunoprecipitation; choice depends on antibody host species for optimal binding. | Protein A for rabbit IgG, Protein G for mouse IgG in IP and co-IP experiments to ensure efficient pull-down. |

| Compatibile Lysis Buffers [19] [20] | Effectively extracts target protein without disrupting protein complexes or assay chemistry. | Using a mild cell lysis buffer (#9803) for co-IP instead of a denaturing RIPA buffer to preserve protein interactions. |

| Protease/Phosphatase Inhibitor Cocktails [19] | Prevents degradation and post-translational modification changes of the target protein during sample preparation. | Added to cell lysis buffers to maintain protein phosphorylation states for phospho-specific assays. |

| Biotin-Free Assay Kits [20] | Eliminates interference from endogenous biotin present in samples like serum or cell culture media. | Used in bead-based assays (e.g., AlphaLISA) when high biotin media (e.g., FBS) causes high background. |

| Reference Standards [1] | Calibrates the assay; should closely match the sample protein in composition and matrix. | Using a well-characterized, stable reference standard that is quantified by a primary method for accurate relative quantification. |

The Critical Role of Protein Quantification in Drug Development Pipelines

Protein quantification is a foundational step in the biopharmaceutical pipeline, from early drug discovery to final product release. Accurate measurement is critical for ensuring drug efficacy, safety, and consistent dosing. This technical support center addresses common challenges and provides solutions to optimize the accuracy of your protein concentration measurements.

Protein Quantification Method Selection Guide

Choosing the appropriate quantification method is the first critical step in ensuring data accuracy. The table below compares the most commonly used techniques to help you select the right assay for your application [1].

| Method | Principle | Detection Range | Key Advantages | Key Limitations | Best for Drug Development Stage |

|---|---|---|---|---|---|

| Bradford Assay | Coomassie dye binding to basic/aromatic residues [10] | ~1-1500 μg/mL [1] | Rapid, simple, compatible with many buffers [10] | Interference from detergents; variable response to different proteins [1] | Discovery (high-speed screening) [1] |

| BCA Assay | Cu²⁺ reduction in alkaline solution (biuret reaction) and BCA chelation [12] | ~0.0005-2000 μg/mL [1] | Good tolerance to many buffer substances; more uniform protein response [1] | Interference from reducing agents and chelators [12] | Discovery & Development (good balance of speed and accuracy) [1] |

| UV Absorbance | Absorption of light at 280 nm by aromatic amino acids | Varies by protein | Non-destructive; direct measurement without standards | Interference from nucleic acids, turbidity, and other UV-absorbing compounds [1] | All stages (quick estimate, requires pure sample) |

| Amino Acid Analysis | Acid hydrolysis and derivatization of amino acids [1] | N/A | Highly accurate and reproducible; considered an absolute method [1] | Complex, slow, requires specialized equipment [1] | Late-stage Development & QC (reference method) |

| ELISA | Antigen-antibody binding with enzymatic detection [5] | High sensitivity (e.g., sub-pg/mL for nELISA) [21] | High specificity and sensitivity; excellent for complex mixtures [5] [22] | Mainly for specific proteins, not total protein; can have false positives/negatives [5] | Development & QC (specific protein/impurity quantification) [1] |

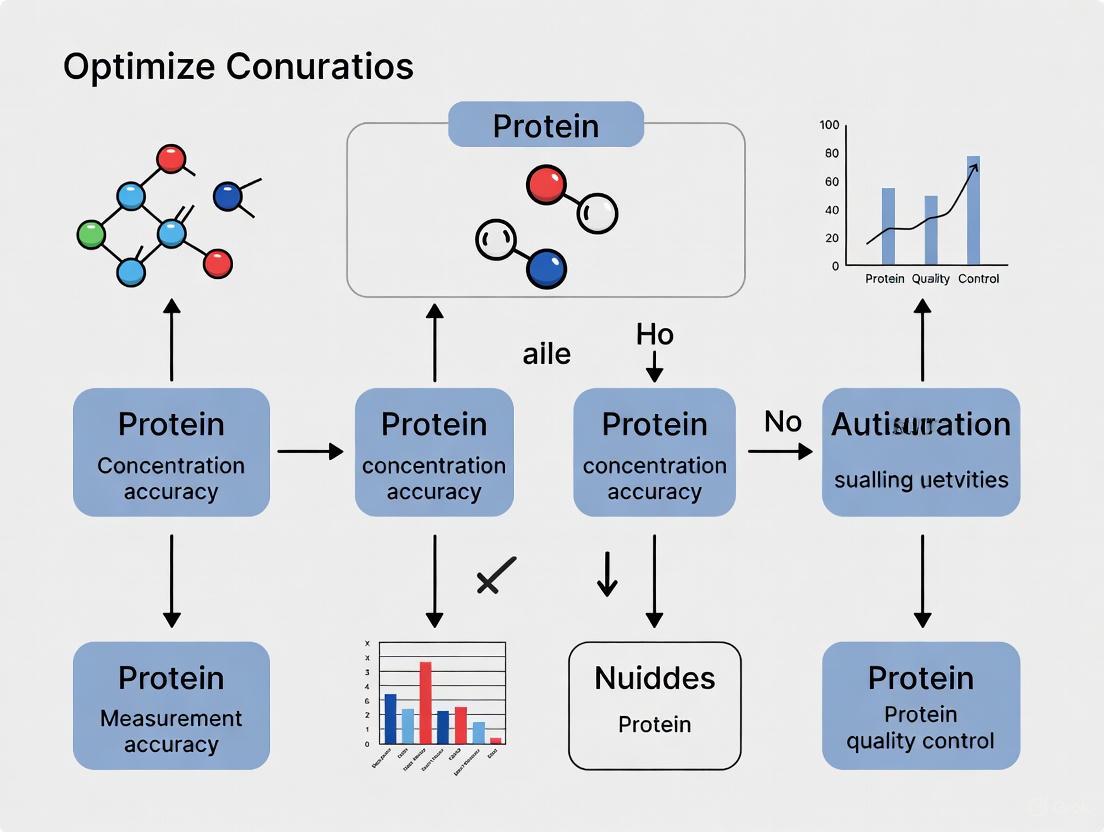

Method Selection Workflow

The following diagram outlines a logical workflow for selecting the most appropriate protein quantification method based on your experimental goals and sample type.

Troubleshooting Common Protein Assay Problems

Even with the correct method chosen, various issues can arise during experimentation. Here are solutions to frequently encountered problems.

| Problem | Possible Cause | Solution |

|---|---|---|

| Low Absorbance | Protein MW < 3-5 kDa | Use an alternative assay (e.g., BCA) for smaller proteins or peptides. |

| Interfering substances | Dilute the sample. Ensure standards are prepared in the same buffer. Dialyze if necessary. | |

| Absorbance Too High | Protein concentration too high | Dilute the sample and repeat the assay. |

| Precipitates Formed | Detergents in protein buffer | Dialyze or dilute the sample to reduce detergent concentration. |

| Dark Blue Color | High alkaline concentration | Dilute or dialyze the sample to bring pH within a compatible range. |

| Inconsistent Standards | Old or improperly stored dye | Replace outdated Bradford reagent (typical shelf life ~12 months). |

| Incorrect wavelength | Ensure absorbance is measured at 595 nm. |

| Problem | Possible Cause | Solution |

|---|---|---|

| Inconsistent Results | Varying incubation temperature | Ensure a consistent incubation temperature (typically 37°C) across all samples/standards. |

| Delays in reading plates | Read all samples at the same time post-incubation; use a timer. | |

| Over-/Under-estimation | Interfering substances (reducing agents, chelators) | Remove substances via dialysis, precipitation, or use a compatible assay kit. |

| Poor standard preparation | Use a fresh standard that resembles your sample protein, prepared in the same buffer. | |

| High Background | Contamination in buffer | Replace the kit or buffer. Use clean cuvettes/microplates. |

Frequently Asked Questions (FAQs)

| Factor | ELISA | Western Blot |

|---|---|---|

| Primary Use | Quantifying specific proteins (e.g., cytokines, biomarkers) in a sample [5]. | Confirming the presence, size, and identity of a specific protein in a complex mixture [5] [6]. |

| Throughput | High. Ideal for screening many samples quickly in a 96-well plate format [5] [22]. | Low. Typically analyzes 10-15 samples per gel, making it slower for large studies [22]. |

| Data Output | Quantitative. Provides precise concentration values [5]. | Semi-Quantitative. Provides relative abundance and molecular weight information [22]. |

| Specificity | High, but can be prone to false positives/negatives if not optimized [5]. | Very high, as it confirms protein identity by molecular weight, and is often used to confirm ELISA results [5] [6]. |

| Information Gained | Presence and concentration of a target. | Presence, size, protein modifications (e.g., phosphorylation), and cleavage events [6] [22]. |

Buffer incompatibility is a common issue. Here is a strategic approach to solve it:

- Dilution: The simplest method. Dilute your sample several-fold in a compatible buffer to reduce the concentration of the interfering substance to a non-inhibitory level. This is only feasible if your starting protein concentration is high enough [12] [10].

- Dialysis or Desalting: Physically remove the interfering substances by transferring the sample into a compatible buffer using dialysis, desalting columns, or buffer exchange kits [12].

- Protein Precipitation: Precipitate your protein using acetone or trichloroacetic acid (TCA). The pellet, once washed, can be re-dissolved in an assay-compatible buffer [12].

- Assay Selection: Choose a more compatible assay. For example, the BCA assay is generally more tolerant of reducing agents than the Bradford assay, which is highly sensitive to detergents [12] [10] [1].

- Pipetting Errors: This is a frequent culprit, especially with small or viscous volumes. Verify your pipetting technique and calibrate your pipettes regularly.

- Sample Homogeneity: Ensure your samples are thoroughly mixed before aliquoting. Protein can adhere to tube walls, leading to uneven concentration.

- Temperature Fluctuations: The color development in assays like BCA is temperature-sensitive. Ensure consistent incubation temperature across all runs [23].

- Instrument Calibration: Regularly calibrate your spectrophotometer or microplate reader to ensure accurate absorbance measurements [23].

The field is moving towards higher multiplexing and sensitivity. A key innovation is the nELISA platform [21]. It combines a DNA-mediated, bead-based sandwich immunoassay with advanced multicolor bead barcoding. This design pre-assembles antibody pairs on target-specific barcoded beads, which spatially separates different assays and prevents reagent cross-reactivity—the main barrier to high-level multiplexing. This technology allows for profiling hundreds of proteins (e.g., a 191-plex inflammation panel) across thousands of samples with high sensitivity and specificity, making it a powerful tool for large-scale phenotypic screening in drug discovery [21].

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function | Key Considerations |

|---|---|---|

| BSA (Bovine Serum Albumin) | The most common protein standard for generating calibration curves in colorimetric assays [10]. | If your target protein's amino acid composition differs greatly from BSA, consider using a different standard (e.g., IgG) for improved accuracy [12] [1]. |

| Compatible Assay Kits | Kits designed to tolerate specific interfering substances (e.g., BCA Reducing Agent Compatible Assay) [12]. | Select based on your sample buffer composition. Always check the manufacturer's compatibility table. |

| Microplates & Cuvettes | Vessels for holding samples during absorbance measurement. | Use glass or plastic cuvettes for Bradford assay, as the dye can react with quartz. Ensure all vessels are clean and scratch-free [10] [23]. |

| High-Quality Antibodies | Critical for immunoassays like ELISA and Western blot (capture and detection) [22]. | For Sandwich ELISA, ensure antibody pairs are raised in different species and bind to non-overlapping epitopes [22]. |

| Blocking Agents (e.g., BSA) | Used to coat unused binding sites on plates or membranes to prevent non-specific antibody binding [22]. | A 1% BSA solution is commonly used. Prepare fresh or store appropriately to prevent contamination. |

Experimental Workflow for Validated Protein Quantification

Adhering to a standardized workflow is crucial for generating reliable and reproducible data, especially in a regulated drug development environment. The following diagram outlines a generalized protocol for protein quantification and assay validation.

Navigating Regulatory Requirements and Pharmacopoeial Methods

In pharmaceutical development and clinical diagnostics, the accuracy of protein concentration measurements is paramount. Regulatory agencies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) mandate strict validation of bioanalytical methods to ensure the safety and efficacy of drugs and biological products [24]. Adherence to these guidelines and pharmacopoeial standards is not optional; it is a fundamental requirement for generating data that is accepted in regulatory submissions worldwide. This guide addresses common challenges and provides troubleshooting advice for maintaining compliance while optimizing the accuracy of protein quantification methods such as ELISA, BCA, and Bradford assays.

Frequently Asked Questions (FAQs) on Regulatory Compliance

Q1: What are the core validation parameters required for a regulatory-compliant protein assay?

According to FDA and EMA guidelines, validating a bioanalytical method like ELISA requires characterizing several key parameters [24]:

- Accuracy and Precision: Closeness of individual measurements to the true value (accuracy) and the reproducibility of the measurement (precision), both within (intra-assay) and between (inter-assay) runs.

- Specificity and Selectivity: The ability of the assay to unequivocally assess the target analyte in the presence of other components, such as impurities or matrix components.

- Linearity and Range: The ability of the assay to obtain results directly proportional to the analyte concentration within a given range.

- Sensitivity: The lowest amount of analyte that can be reliably detected, often defined as the Lower Limit of Detection (LLOD).

- Robustness: A measure of the assay's capacity to remain unaffected by small, deliberate variations in method parameters.

Q2: What are the consequences of using a poorly validated assay?

A poorly validated assay can lead to several critical errors, including the generation of false positive and false negative results [24]. Common issues like insufficient plate washing, excessive detection reagent, or cross-reactivity can yield a high background signal, compromising data accuracy. Furthermore, a lack of lot-to-lot consistency in reagents can also lead to erroneous results, potentially jeopardizing drug safety assessments and leading to costly delays in product development.

Q3: How do I choose between BCA and Bradford methods for my regulatory submission?

The choice depends on the specific sample composition and potential interferents. The table below compares the two methods:

| Parameter | BCA Assay [25] | Bradford Assay [25] [26] |

|---|---|---|

| Principle | Reduction of Cu²⁺ to Cu⁺ in alkaline medium, detected by BCA dye. | Shift in absorbance of Coomassie G-250 dye upon binding protein. |

| Compatible with Detergents | High (Tolerates up to 5% SDS, Triton X-100, Tween) | Low (SDS must be <1%; Triton X-100 <0.1%) |

| Compatible with Reducing Agents | Low (Interfered by DTT, β-mercaptoanol, TCEP, EDTA) | High (Tolerates DTT, β-mercaptoanol, TCEP, EDTA) |

| Protein-to-Protein Variation | Moderate (Influenced by cysteine, tyrosine, tryptophan) | High (Influenced by arginine and lysine content) |

| Key Advantage | Robust in the presence of detergents. | Fast, simple, and tolerant of reducing agents. |

Troubleshooting Guides for Common Experimental Issues

Issue 1: High Background or Non-Specific Signal in Immunoassays

A high background signal can mask true results and lead to inaccurate quantification.

| Possible Cause | Recommended Solution |

|---|---|

| Insufficient Blocking | Optimize the type, concentration, and incubation time of the blocking buffer (e.g., 5% BSA or non-fat dry milk) [24] [27]. |

| Antibody Concentration Too High | Titrate both primary and secondary antibodies to find the optimal dilution that maximizes signal-to-noise ratio [27]. |

| Incomplete Washing | Ensure thorough washing throughout the protocol to remove unbound reagents. Increase wash times or the number of wash cycles [24] [27]. |

| Cross-reactivity of Antibodies | Check antibody specification sheets for validated applications. Pre-absorbed antibodies may be necessary for complex samples [24]. |

Issue 2: No Signal or Weak Signal

The absence or weakness of an expected signal is a common frustration that can stem from multiple sources.

| Possible Cause | Recommended Solution |

|---|---|

| Antibody Incorrect or Inactive | Use a positive control to verify antibody activity. Ensure antibodies are stored correctly and not used beyond their expiration date [27]. |

| Insufficient Antigen/Protein | Increase the amount of protein loaded. Check for protein degradation by using fresh protease inhibitors during sample preparation [27]. |

| Inefficient Transfer (Western Blot) | Use Ponceau S staining or Coomassie staining of the gel post-transfer to confirm protein has moved to the membrane [27]. |

| Incompatible Buffer Components | For BCA, avoid chelators like EDTA and reducing agents. For Bradford, avoid high concentrations of detergents [25]. |

Issue 3: Poor Standard Curve Linearity

A non-linear or poorly fitting standard curve prevents accurate quantification of unknown samples.

| Possible Cause | Recommended Solution |

|---|---|

| Inaccurate Pipetting or Standard Preparation | Use calibrated pipettes and prepare fresh serial dilutions of the standard carefully [25]. |

| Assay Range Exceeded | Ensure the absorbance values of unknown samples fall within the range of the standard curve. Dilute samples as needed [24]. |

| Matrix Effects | Match the standard diluent to the sample matrix as closely as possible to ensure similar behavior [24]. |

Essential Experimental Protocols

This method is ideal for samples containing detergents.

- Prepare Standard Dilutions: Create a series of Bovine Serum Albumin (BSA) standards in a buffer matching your sample matrix, covering a range from 0 to 1000 µg/mL.

- Prepare BCA Working Reagent: Mix reagents A and B in a 50:1 ratio. This working reagent is stable at room temperature for 24 hours.

- Add Samples and Reagent: Pipette 20 µL of each standard and unknown sample into a microplate or test tube. Add 200 µL of BCA working reagent to each.

- Incubate and Measure: Incubate the plate or tubes at 37°C for 30 minutes. Cool to room temperature.

- Read Absorbance: Measure the absorbance at 562 nm using a plate reader or spectrophotometer.

- Calculate Concentrations: Subtract the average blank absorbance from all standards and samples. Plot the standard curve (Absorbance vs. Concentration) and use the linear equation to calculate the concentration of your unknowns.

This method is fast and tolerant of reducing agents.

- Prepare Standard Dilutions: Prepare BSA or γ-globulin standards as described for the BCA assay.

- Add Samples and Reagent: Pipette standards and unknowns into a microplate. Add Bradford reagent to each well.

- Incubate and Measure: Incubate at room temperature for 5-10 minutes. The color is stable for up to one hour.

- Read Absorbance: Measure the absorbance at 595 nm.

- Calculate Concentrations: Generate a standard curve and calculate unknown concentrations as described in the BCA protocol.

Workflow Visualization: Bioanalytical Method Validation

The following diagram outlines the logical workflow for establishing a compliant and robust protein quantification method.

The Scientist's Toolkit: Key Research Reagent Solutions

The table below lists essential materials and their functions for setting up protein quantification assays.

| Item | Function | Key Considerations |

|---|---|---|

| BCA Assay Kit [25] | Colorimetric quantification of total protein based on the reduction of Cu²⁺. | Choose based on compatibility with detergents; avoid with reducing agents. |

| Bradford Assay Kit [25] [26] | Colorimetric quantification based on dye binding to arginine/lysine residues. | Ideal for quick results and samples with reducing agents; avoid with detergents. |

| Microplate Reader | Measures absorbance in 96-well or 384-well plates for high-throughput analysis. | Must have filters for appropriate wavelengths (e.g., 562nm for BCA, 595nm for Bradford). |

| BSA (Bovine Serum Albumin) | Serves as the standard reference protein for generating calibration curves. | Ensure high purity and prepare fresh dilutions for accurate standard curves. |

| Coated ELISA Plates [24] | Solid phase pre-coated with capture antibody for specific antigen detection. | Check lot-to-lot consistency to prevent variability and ensure assay reproducibility. |

| High-Affinity Antibodies [24] | Primary and secondary antibodies for specific target detection in immunoassays. | Must be validated for the specific application (e.g., Western blot, ELISA). Titrate for optimal signal. |

| Blocking Buffer (e.g., BSA, Non-fat Milk) [24] [27] | Prevents non-specific binding of antibodies to the plate or membrane, reducing background. | Type must be optimized; some antibodies may cross-react with proteins in milk. |

Strategic Method Selection and Application Across the Research Pipeline

Accurate protein quantification is a foundational step in biomedical research and drug development, directly impacting the validity of downstream analyses and experimental conclusions. The accuracy of these measurements is highly dependent on the specific combination of your protein sample and the buffer components it is in. This guide provides a structured framework to navigate the complex landscape of protein assays, helping you select the optimal method to ensure reliable and reproducible results for your specific experimental conditions.

Selecting the right quantification method is the first critical step. The table below summarizes the most common colorimetric and fluorescent protein assays, their principles, advantages, and key limitations [28].

| Assay Method | Fundamental Principle | Key Advantages | Major Disadvantages |

|---|---|---|---|

| UV Absorption | Measures absorbance of aromatic amino acids (Tyr, Trp) at 280 nm [28]. | Simple and quick; no reagents required [28]. | High error with protein mixtures; interfered by any UV-absorbing substances (e.g., nucleic acids) [28]. |

| Bradford (Dye-Binding) | Coomassie dye binds proteins under acidic conditions, causing a spectral shift [28] [29]. | Fast, easy, and compatible with reducing agents and metal chelators [28]. | Incompatible with detergents; high protein-to-protein variation [28] [29]. |

| BCA (Bicinchoninic Acid) | Copper ions (Cu²⁺) reduced by proteins in an alkaline medium (Biuret reaction); BCA chelates the reduced Cu⁺ [28]. | Compatible with most detergents; less protein-to-protein variation than Bradford [28]. | Incompatible with reducing agents (e.g., DTT) and copper-chelating agents [28] [30]. |

| Lowry | Copper-protein complex (Biuret) enhanced by the Folin-Ciocalteu reagent [28]. | Linear response curve; less protein-to-protein variation than dye-based assays [28]. | Incompatible with detergents, reducing agents, and chelators [30]. |

| Fluorescent Assays | Protein-binding fluorescent dyes (e.g., NanoOrange, Qubit assays) [28]. | Excellent sensitivity; timing is not critical; suitable for high-throughput automation [28]. | Requires a specialized instrument (fluorometer) [28]. |

The Decision Matrix: Matching Your Sample to the Assay

The presence of interfering substances in your sample buffer is the single greatest factor affecting accuracy. Use the following flowchart and compatibility table to guide your selection.

Figure 1: A workflow to guide the initial selection of a protein assay based on the presence of common interfering substances [28] [30].

Matrix of Common Interfering Substances [28] [30] [1]

| Interfering Substance | Bradford Assay | BCA Assay | Lowry Assay | Fluorescent Assays |

|---|---|---|---|---|

| Detergents (e.g., Triton X-100, SDS) | Not Compatible | Compatible | Not Compatible | Varies by assay; generally low tolerance for additional detergents [30] |

| Reducing Agents (e.g., DTT, β-mercaptoethanol) | Compatible | Not Compatible | Not Compatible | Generally Compatible [30] |

| Chelators (e.g., EDTA) | Compatible | Not Compatible | Not Compatible | Information Not Available |

| Salts, Solvents, Buffers | Mostly Compatible [28] | Mostly Compatible | Mostly Compatible | Mostly Compatible [30] |

FAQs and Troubleshooting Guides

Q1: My protein assay results are inconsistent. What are the most common causes?

- Incompatible Buffer Components: This is the most frequent issue. Cross-reference your buffer recipe with the compatibility table above [28] [30].

- Inaccurate Standard Curve: The standard curve must be prepared fresh each time the assay is performed, especially for non-linear assays like Bradford. Using expired or improperly stored standards will also lead to errors [28] [30].

- Protein-to-Protein Variation: Different proteins can yield different color responses. Bovine Serum Albumin (BSA) is a common standard, but if high accuracy is required, a purified version of your target protein is ideal [28] [29].

- Improper Pipetting: Small volumetric errors are magnified in microplate-scale assays. Use calibrated pipettes and good technique [30].

Q2: How can I overcome buffer incompatibility without changing my assay?

- Sample Dilution: Diluting your sample several-fold in a compatible buffer can reduce the concentration of the interfering substance below its threshold of interference. This is only feasible if your protein concentration is high enough to remain within the working range after dilution [30].

- Dialysis or Desalting: These techniques physically separate your protein from small interfering molecules (e.g., DTT, salts) by exchanging the buffer for one that is compatible with your chosen assay [28] [30].

- Protein Precipitation: Precipitate your protein using acetone or trichloroacetic acid (TCA), remove the supernatant containing the interferent, and then re-dissolve the protein pellet in a compatible buffer [30].

Q3: When should I use BSA versus IgG as my protein standard?

- Bovine Serum Albumin (BSA): This is the most widely used general-purpose standard. It is inexpensive, highly pure, and produces a consistent color response [28].

- Immunoglobulin G (IgG): Use IgG (or Bovine Gamma Globulin, BGG) as your standard when you are quantifying antibodies. IgG produces a color response curve more similar to other immunoglobulins, providing greater accuracy for these specific samples [28].

Q4: My sample volume is very small and the protein is dilute. What are my options?

For dilute samples, sensitivity becomes paramount. Micro BCA and fluorescent assays (e.g., NanoOrange, Qubit) offer excellent sensitivity and are well-suited for quantifying total protein in dilute samples, often requiring less sample volume [28].

Detailed Experimental Protocols

Protocol 1: BCA Assay (Microplate Procedure)

This copper-based assay is ideal for samples containing detergents but lacking reducing agents [28].

Research Reagent Solutions:

- BSA Standard: Prepare a series of BSA dilutions in the same buffer as your unknown samples.

- BCA Working Reagent (WR): Mix Reagent A (sodium carbonate, BCA) with Reagent B (copper sulfate) at a 50:1 ratio.

Methodology:

- Prepare Standard Curve: Pipette 0, 2.5, 5, 10, 15, and 20 µL of BSA standards in duplicate into a microplate. Bring the volume in each well to 20 µL with buffer.

- Add Unknown Samples: Pipette 20 µL of each unknown sample into wells.

- Add BCA Reagent: Add 200 µL of the BCA WR to each well. Seal the plate and mix thoroughly.

- Incubate: Incubate the plate at 37°C for 30 minutes or at room temperature for 2 hours. The higher temperature increases sensitivity.

- Measure Absorbance: Cool the plate to room temperature. Measure the absorbance at 562 nm on a plate reader.

- Calculate Concentration: Generate a standard curve from the blank-corrected averages of the standard replicates and use the linear equation to determine the concentration of your unknowns.

Protocol 2: Overcoming Interference via Protein Precipitation

This protocol is effective for removing small interfering molecules like DTT [30].

Research Reagent Solutions:

- Precipitation Reagent: 100% w/v Trichloroacetic Acid (TCA).

- Wash Solvent: Acetone, chilled to -20°C.

- Compatible Solubilization Buffer: A buffer known to be compatible with your chosen assay (e.g., PBS).

Methodology:

- Precipitate: Add 100% TCA to your protein sample to a final concentration of 10-20% TCA. Incubate on ice for 10-30 minutes. A protein pellet should form.

- Centrifuge: Centrifuge at >10,000 × g for 10 minutes to pellet the protein.

- Wash: Carefully decant the supernatant. Wash the pellet with ice-cold acetone to remove residual TCA and interferents. Centrifuge again and decant.

- Dry: Air-dry the pellet briefly to evaporate residual acetone.

- Re-dissolve: Solubilize the protein pellet in a compatible buffer using vortexing and gentle heating if necessary.

- Assay: Proceed with your chosen protein assay.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in Protein Quantification |

|---|---|

| Bovine Serum Albumin (BSA) | The most common protein standard for generating calibration curves [28]. |

| Bovine Gamma Globulin (BGG) | A more appropriate standard when quantifying antibody samples [28]. |

| Compatible Lysis Buffers | Buffers formulated without detergents or reducing agents for universal compatibility, or specific buffers matched to your assay choice. |

| Dialysis Cassettes/Desalting Columns | For buffer exchange to remove small interfering substances from protein samples [28] [30]. |

| Trichloroacetic Acid (TCA) / Acetone | For precipitating proteins to separate them from interfering substances in the solution [30]. |

| Microplates and Cuvettes | The vessel for performing the assay and measuring absorbance/fluorescence. |

| Spectrophotometer / Plate Reader | Instrument required to measure the colorimetric (absorbance) or fluorescent signal produced by the assay [28]. |

Advanced Considerations: Buffer Composition and Protein Stability

The buffer itself can profoundly influence your protein's state and thus the quantification result. When choosing a buffer, consider:

- Optimal pH: Work at a pH that maintains your protein's stability and activity. The buffer's pKa should be within one pH unit of your experimental pH for effective buffering capacity [31].

- Additive Effects: A single component may be below its interference threshold, but a combination of several substances in a complex sample buffer can collectively interfere with the assay [30].

- Protein Stability Screening: Different buffers can promote or prevent protein aggregation and denaturation. If possible, screen your protein's stability in different buffer conditions to ensure you are quantifying native, soluble protein [31].

Methodologies for Drug Discovery vs. Clinical Release Testing

Frequently Asked Questions (FAQs)

Q1: Why is the choice of protein quantification method different in the drug discovery phase compared to the clinical release testing phase?

The requirements for speed, precision, and regulatory compliance differ fundamentally between these stages [1].

- Drug Discovery: The primary goal is speed and sensitivity. Materials are often available in low quantities and purity. Methods need to be fast and flexible to screen many candidates. Common techniques include colorimetric assays (e.g., BCA, Lowry) and simple 1D gels [1].

- Clinical Release Testing: The primary goal is accuracy, robustness, and regulatory compliance. The method must be rigorously validated to ensure exact dosing for patient safety. Techniques described in pharmacopoeias, such as amino acid analysis, are preferred for easier regulatory acceptance [1].

Q2: What are the most common interfering substances in protein quantification assays, and how can I troubleshoot them?

Interference is a major cause of inaccurate quantification. The table below summarizes common issues and solutions [1] [32].

| Interfering Substance | Effect on Quantification | Troubleshooting Strategies |

|---|---|---|

| Detergents | Can disrupt dye binding in colorimetric assays, leading to inaccurate readings. | Use a detergent-compatible assay (e.g., amido-black). Dialyze or desalt the sample to remove detergents [1]. |

| Reducing Agents & Chaotropes | May interfere with the chemistry of certain assays. | Check the assay's tolerance levels for these agents. A robust assay like amido-black may be less susceptible [1]. |

| Nucleic Acids | Absorb light at similar wavelengths to proteins in UV absorbance methods, causing overestimation. | Switch to a fluorescence-based method (e.g., Qubit assay) that is minimally affected by nucleic acids [32]. Use a purification step to remove nucleic acids [32]. |

| Other Buffer Components | Salts, sugars, and lipids can affect assay chemistry. | Always include a buffer-only negative control to account for background interference [1]. Perform a serial dilution of your sample; if the results are non-linear, interference is likely. |

Q3: What does a "validated" protein quantification method for clinical release entail?

According to ICH guidelines, a validated quantitative method must demonstrate several key parameters [1]:

- Accuracy: How close the measured value is to the true value.

- Precision: The closeness of agreement between a series of measurements (including repeatability and intermediate precision).

- Specificity: The ability to assess the analyte unequivocally in the presence of other components.

- Linearity and Range: The interval over which the method provides results with direct proportionality to analyte concentration.

- Detection Limit (LOD) and Quantification Limit (LOQ): The lowest amount of protein that can be detected or quantified with acceptable accuracy and precision [1].

Q4: My protein is unstable. How can I ensure reliable quantification?

Protein degradation during sample preparation will make accurate quantification impossible [1].

- Immediate Processing: Keep samples on ice and process them quickly.

- Inhibit Proteases: Add protease inhibitor cocktails to your lysis or storage buffers.

- Controlled Denaturation: Deactivate proteases by denaturing the sample in urea or SDS, but only if your chosen quantification assay can tolerate these substances [1].

Methodology Comparison Tables

Table 1: Comparison of Protein Quantification Methods by Development Stage

This table compares the key characteristics of methods typically used in different phases of drug development [1] [33].

| Method | Primary Use Case | Key Advantages | Key Limitations | Regulatory Acceptance |

|---|---|---|---|---|

| Colorimetric Assays (BCA, Bradford) | Drug Discovery | Fast, cost-effective, works with a broad range of proteins, high-throughput compatible. | Susceptible to interference from detergents and reducing agents; measures total protein, not specific drug substance [1]. | Not typically used for final product release. |

| Amino Acid Analysis | Clinical Release Testing | Highly accurate and reproducible; considered an absolute quantification method [1]. | Technically complex, requires specialized equipment, time-consuming [1]. | High; easily accepted by regulatory authorities [1]. |

| Mass Spectrometry (e.g., AQUA) | Drug Discovery / Characterization | High specificity for the drug substance; can quantify specific isoforms and post-translational modifications [1]. | Expensive, requires expert operation, complex data analysis. | Growing acceptance, particularly for characterizing complex molecules. |

| ELISA | Impurity Testing / Potency Assays | Extremely high sensitivity and specificity for a particular protein or impurity [1]. | Antibody specificity must be thoroughly characterized; may not distinguish between active and inactive forms [1]. | Well-accepted for specific applications (e.g., host cell protein assays). |

| Fluorescence-Based (e.g., Qubit) | Drug Discovery (Sensitive Applications) | High sensitivity, minimal interference from nucleic acids, requires small sample volumes [32]. | Requires a dedicated fluorometer, more expensive per sample than colorimetric assays. | Not typically used for final product release. |

Table 2: Key Validation Parameters for Quantitative Assays in Clinical Release

This table defines the critical parameters that must be validated for a protein quantification method used in clinical release testing, based on ICH guidelines [1].

| Validation Parameter | Definition | Importance in Clinical Release |

|---|---|---|

| Accuracy | The closeness of agreement between the measured value and a true accepted reference value. | Ensures the drug product contains the exact, labeled dose for patient safety and efficacy [1]. |

| Precision | The closeness of agreement between a series of measurements from multiple sampling. | Ensures the manufacturing process is consistent and controlled, batch after batch [1]. |

| Repeatability | Precision under the same operating conditions over a short time (intra-assay). | Demonstrates the reliability of the assay within a single run [1]. |

| Intermediate Precision | Precision within the same laboratory (different days, different analysts). | Demonstrates the assay's robustness to normal lab variations [1]. |

| Specificity | The ability to measure the analyte accurately in the presence of other components (excipients, impurities). | Ensures the measurement is of the drug protein and is not skewed by the formulation matrix [1]. |

| Linearity | The ability to obtain results directly proportional to the concentration of the analyte. | Confirms the assay works accurately across the required concentration range (e.g., dose variations) [1]. |

| Range | The interval between the upper and lower concentrations for which linearity, accuracy, and precision are demonstrated. | Defines the acceptable concentrations for which the assay is validated [1]. |

Experimental Workflow & Visualization

Workflow for Protein Quantification Method Selection

This diagram outlines a logical decision process for selecting and validating a protein quantification method based on the stage of drug development and specific needs.

Protein Quantification Assay Workflow

This diagram details the general workflow for performing a protein quantification, using a fluorescence-based assay as an example.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Reagents and Kits for Protein Quantification

This table lists key reagents, kits, and instruments used in protein quantification, along with their primary function in an experiment.

| Reagent / Kit / Instrument | Primary Function in Protein Quantification |

|---|---|

| BCA (Bicinchoninic Acid) Assay Kit | A colorimetric method for determining total protein concentration based on the reduction of Cu²⁺ to Cu⁺ in an alkaline environment. |

| Bradford Assay Kit | A colorimetric method that uses Coomassie dye, which binds to proteins and shifts its absorbance maximum. |

| Qubit Protein Assay Kit | A highly sensitive fluorescence-based method that uses a dye selective for proteins, minimizing interference from contaminants [32]. |

| Amino Acid Analysis Service | Provides absolute quantification of protein concentration by hydrolyzing the protein and quantifying its constituent amino acids [1]. |

| Bovine Serum Albumin (BSA) | The most common protein used to prepare standard curves for calibrating colorimetric and fluorescent assays [32]. |

| Spectrophotometer / Plate Reader | An instrument that measures the absorbance of light by a sample, used for reading colorimetric assays like BCA and Bradford. |

| Fluorometer | An instrument that measures the intensity of fluorescent light emitted by a sample, required for assays like the Qubit system [32]. |

| HPLC System with UV Detector | Used for high-precision separation and quantification of proteins or peptides, often in a GMP environment for release testing [1] [33]. |

Frequently Asked Questions (FAQs)

Q1: Why is it critical to distinguish between quantifying the drug substance and total protein content?

A: The distinction is fundamental to drug safety and efficacy. Providing an exact and reproducible drug dose to a patient is critical [1]. If your goal is to measure the active therapeutic protein itself (the drug substance), you need a specific assay. If you need to measure the total protein content in a sample, which may include impurities, host cell proteins, or degraded products, you use a general assay. Using the wrong type of assay can lead to inaccurate dosing, miscalculation of impurity levels, and ultimately, unreliable data for regulatory submissions [1] [34].

Q2: What are the primary types of assays for specific versus general quantification?

A: The choice of assay depends entirely on your quantification goal. The table below summarizes the main categories:

| Quantification Goal | Description | Common Assay Technologies |

|---|---|---|

| Total Protein Content | Measures all proteins in a mixture, including the drug substance, host cell proteins, and impurities [1]. | Colorimetric assays (Bradford, Lowry, BCA) [28] [35], UV Absorbance at 280 nm [36] [35]. |

| Drug Substance (Specific Protein) | Quantifies only the active therapeutic protein, often in the presence of a complex matrix like a formulation or biological fluid [1] [36]. | Immunoassays (ELISA) [1] [3], Mass Spectrometry (LC-MS/MS) [1] [37] [36], Western Blots [1]. |

Q3: My sample is in a complex buffer. How do I choose a compatible assay?

A: Buffer components are a major source of interference. Selecting an assay tolerant of your sample's matrix is crucial for accuracy. The following table compares the compatibility of common total protein assays with various substances.

| Assay Method | Principle | Key Interfering Substances | Compatible Substances |

|---|---|---|---|

| Bradford Assay | Dye-binding to basic amino acids (Arg, Lys) [28] [36]. | Detergents (SDS, Triton X-100) [28] [36], strongly alkaline buffers [35]. | Reducing agents (DTT), metal-chelating agents, most salts and solvents [28]. |

| BCA Assay | Copper reduction by peptide bonds in alkaline conditions (biuret reaction) [28] [35]. | Reducing agents (DTT, β-mercaptoethanol) [28], metal chelators (EDTA, EGTA) [28]. | Detergents [28], most salts [35]. |

| Lowry Assay | Copper reduction followed by Folin-Ciocalteu reaction [36] [35]. | Reducing agents, carbohydrates, ammonium ions, Tris buffer [35]. | Most surfactants [28]. |

| UV Absorbance at 280 nm | Absorption by aromatic amino acids (Trp, Tyr, Phe) [36] [35]. | Any UV-absorbing substance, including nucleic acids, nucleotides, and other aromatic compounds [28] [36]. | Volatile buffers that do not absorb at 280 nm [35]. |

Q4: How can I troubleshoot a protein assay that is producing inconsistent results?

A: Inconsistent results often stem from improper sample handling, incorrect standard selection, or unaccounted-for interference. Follow this troubleshooting guide for common issues.

| Problem | Possible Causes | Potential Solutions |

|---|---|---|

| High Background/Inaccurate Reading | Interference from buffer components (detergents, reducing agents) [28]. | • Dialyze or desalt the sample to remove small interfering substances [28]. • Precipitate the protein and re-dissolve it in a compatible buffer [28]. • Switch to a more compatible assay (see Table 2). |

| Poor Standard Curve Linearity | • Improper standard preparation.• Protein-to-protein variation (especially in dye-binding assays) [28] [38]. | • Ensure the standard is prepared in the same buffer as the unknown samples [28]. • Use a purified version of your protein of interest as a standard, if possible. Otherwise, BSA or IgG are common choices [28]. |

| Low Sensitivity | Protein concentration is below the assay's detection limit [38]. | • Concentrate your sample. • Use a more sensitive assay (e.g., switch from Bradford to BCA or a fluorescent assay) [28]. • For very low concentrations, consider a standard addition method to improve accuracy [38]. |

| Overestimation of Target Protein | Using a total protein assay (e.g., BCA) on an impure sample to quantify a specific protein [3]. | • Use a specific assay like ELISA or LC-MS/MS for the target protein [3]. • Employ a purification step before quantification with a general assay. |

The Scientist's Toolkit: Essential Research Reagents and Materials

The following table lists key reagents and materials essential for performing accurate protein quantification, along with their primary functions.

| Item | Function & Importance |

|---|---|

| Bovine Serum Albumin (BSA) | A widely used reference protein for generating standard curves in colorimetric assays due to its high purity, stability, and low cost [28] [34]. |

| Compatible Lysis Buffers | Buffers for extracting proteins that are free of interfering substances (like strong reducing agents or detergents) specific to the chosen assay, ensuring accurate quantification [28]. |

| Microplate Reader | An instrument for measuring absorbance or fluorescence in plate-based assays, enabling high-throughput analysis of multiple samples simultaneously [28]. |

| Pierce BCA Protein Assay Kit | A commercial kit exemplifying the BCA method, providing pre-formulated reagents for precise, sensitive, and reproducible total protein quantification [38] [39]. |

| 96-Well Plates with Membrane Bottom | Specialized plates used in validated, robust assays for isolating protein-dye complexes, improving reproducibility by enabling reproducible washing steps [34]. |

| Tandem Mass Tags (TMT) | Isobaric labels used in advanced mass spectrometry (e.g., SCoPE-MS) for multiplexed, relative quantification of proteins across different samples, such as single cells [37]. |

| Primary & Secondary Antibodies | Essential reagents for specific quantification assays like ELISA and Western blot, providing the high specificity needed to detect and measure a target protein amidst a complex mixture [3]. |

| Dialysis Cassettes/Columns | Tools for buffer exchange, allowing for the removal of small, interfering substances (e.g., DTT, salts) from protein samples prior to quantification [28]. |

Experimental Protocols & Workflows

Workflow: Selecting and Validating a Protein Quantification Assay

The following diagram outlines a logical workflow for selecting, optimizing, and validating a protein quantification method, crucial for research and regulatory compliance.

Protocol: Direct Quantification of Protein in Liposomes using BCA Assay

This protocol, adapted from [39], is an example of a direct quantification method, which is more accurate than indirect methods that measure un-encapsulated protein.

1. Objective: To directly determine the encapsulation efficiency of a model protein (Ovalbumin, OVA) within liposomal formulations.

2. Materials:

- Pierce Micro BCA Protein Assay Kit

- Liposome samples (neutral, anionic, and cationic)

- Bovine Serum Albumin (BSA) standards

- 96-well plate

- Microplate reader capable of measuring absorbance at 562 nm