Mastering DLS Validation for Biopharmaceutical QC: A Complete Guide from Method Development to Regulatory Compliance

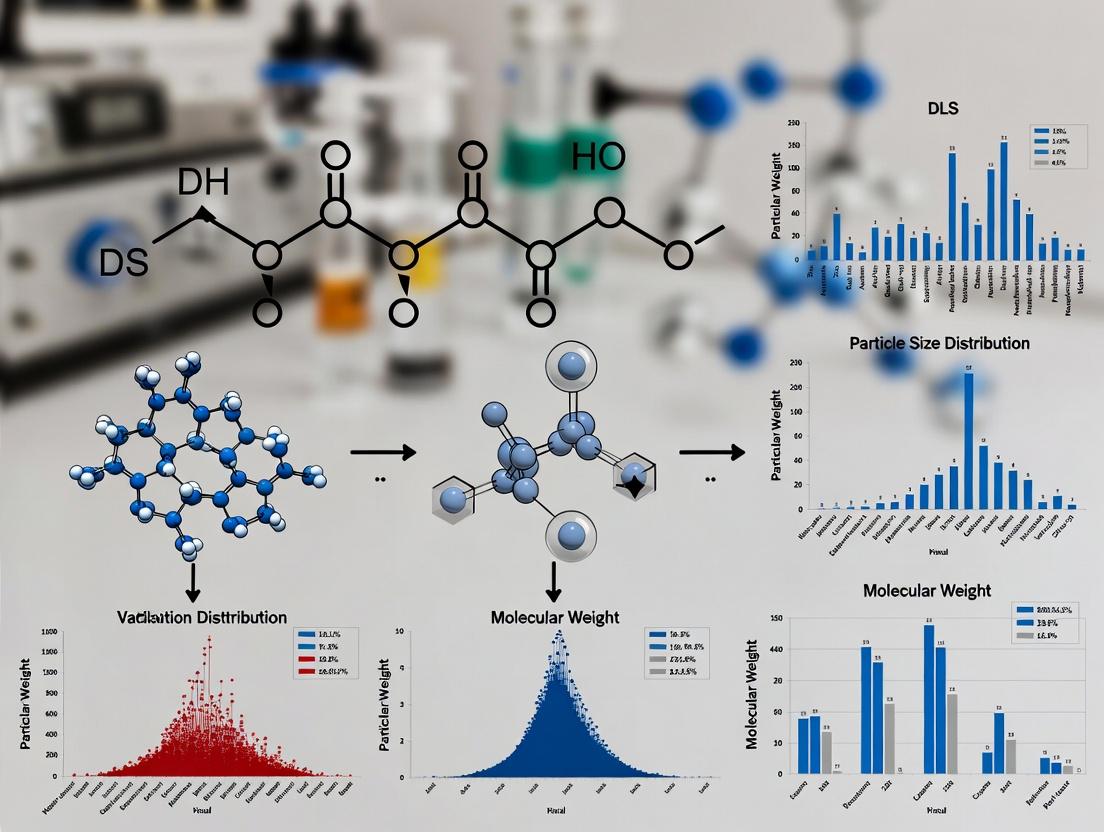

This comprehensive guide details the application of Dynamic Light Scattering (DLS) for biopharmaceutical quality control, targeting researchers and development professionals.

Mastering DLS Validation for Biopharmaceutical QC: A Complete Guide from Method Development to Regulatory Compliance

Abstract

This comprehensive guide details the application of Dynamic Light Scattering (DLS) for biopharmaceutical quality control, targeting researchers and development professionals. It explores the foundational principles of DLS for analyzing protein size, aggregation, and stability. The article provides a step-by-step methodology for method development, optimization of SOPs, and troubleshooting common pitfalls. It concludes with a robust framework for analytical method validation, comparing DLS to orthogonal techniques like SEC-MALS and NTA, ensuring data integrity for regulatory filings and critical quality attribute (CQA) assessment.

What is DLS in Biopharma QC? Core Principles, Capabilities, and Critical Quality Attributes

Within biopharmaceutical quality control (QC), the validation of analytical methods for characterizing therapeutic proteins, vaccines, and viral vectors is paramount. Dynamic Light Scattering (DLS) has emerged as a cornerstone technique for assessing the hydrodynamic size and size distribution (polydispersity) of nanoparticles and macromolecules in their native state. This comparison guide objectively evaluates the performance of a modern DLS instrument against key alternative sizing techniques, providing experimental data to inform method selection for QC research focused on product stability, aggregation, and lot-to-lot consistency.

Core Principles & Measurement Parameters

DLS measures the Brownian motion of particles in suspension by analyzing the fluctuations in scattered laser light intensity. The diffusion coefficient (D) is derived from these fluctuations using an autocorrelation function. The hydrodynamic diameter (dH) is then calculated via the Stokes-Einstein equation, representing the size of a sphere that diffuses at the same rate as the particle. Polydispersity, reported as a Polydispersity Index (PDI), quantifies the breadth of the size distribution. A low PDI (<0.1) indicates a monodisperse sample, while higher values suggest a heterogeneous mixture.

Experimental Protocol for DLS Validation in Biopharmaceuticals

A standard DLS protocol for protein therapeutic analysis is as follows:

- Sample Preparation: The monoclonal antibody (mAb) or protein sample is buffer-exchanged into a formulation buffer (e.g., histidine buffer) via centrifugal filtration to remove dust and large aggregates. A concentration series (e.g., 0.1, 0.5, 1.0, 2.0 mg/mL) is prepared.

- Instrument Calibration: The DLS instrument is validated using a certified latex standard of known diameter (e.g., 60 nm ± 3 nm).

- Measurement: 70 µL of each sample is loaded into a low-volume quartz cuvette. Measurements are performed at 25°C with an equilibration time of 120 seconds. A minimum of 10 acquisitions (5-10 seconds each) are taken per sample.

- Data Analysis: The intensity-weighted size distribution and the PDI (derived from the cumulants analysis) are recorded. Data from the concentration series is analyzed to identify and exclude measurements affected by inter-particle interactions (e.g., concentration-dependent size increases).

Performance Comparison: DLS vs. Alternative Sizing Techniques

The following table summarizes a comparative analysis of DLS against other common sizing techniques used in biopharmaceutical development.

Table 1: Comparison of Sizing Techniques for Biopharmaceutical QC

| Feature | Dynamic Light Scattering (DLS) | Static Light Scattering (SLS) / MALS | Nanoparticle Tracking Analysis (NTA) | Analytical Ultracentrifugation (AUC) |

|---|---|---|---|---|

| Measured Parameter | Hydrodynamic diameter (dH) | Radius of gyration (Rg), Molar Mass | Hydrodynamic diameter (dH) | Sedimentation coefficient, Molar Mass |

| Size Range | ~0.3 nm – 10 µm | ~10 nm – 1 µm | ~30 nm – 2 µm | ~0.5 nm – 10 µm |

| Polydispersity Output | Polydispersity Index (PDI) | Can indicate heterogeneity | Particle-by-particle size distribution | High-resolution size distribution |

| Sample Concentration | High (0.1-10 mg/mL for proteins) | Low to Moderate | Very Low (107-109 particles/mL) | Moderate |

| Key Advantage for QC | Rapid, non-destructive, minimal sample prep, primary technique for subvisible particles. | Provides absolute molar mass and Rg/dH shape factor. | Visual validation, high-resolution for polydisperse samples, concentration count. | "Gold standard" for complex mixtures, resolves oligomers. |

| Limitation for QC | Intensity-weighted; highly sensitive to large aggregates/impurities. | Complex data analysis; often coupled with separation techniques. | Lower throughput, user-dependent settings, less ideal for very small proteins (<30nm). | Very low throughput, requires significant expertise. |

| Typical Data (mAb Sample) | dH: 11.2 nm; PDI: 0.06 | Mw: 148 kDa; Rg: 5.8 nm | dH (Mode): 12.1 nm; Conc.: 8.2e12 particles/mL | Identifies monomer (95%), dimer (4.5%), fragment (0.5%). |

Supporting Experimental Data: A recent inter-laboratory study evaluating a stressed NIST monoclonal antibody (RM 8671) demonstrated strong correlation between DLS and AUC for monomer size determination. DLS reported a dH of 10.8 ± 0.3 nm (PDI: 0.05) for the unstressed mAb, while AUC derived a similar hydrodynamic size. However, DLS showed greater sensitivity to trace aggregates (<0.1% by mass) than AUC, evident from a slight tailing in the intensity distribution, underscoring its utility as an early indicator of instability.

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for DLS in Biopharmaceutical QC

| Item | Function in DLS Experiments |

|---|---|

| Certified Nanosphere Size Standards | (e.g., NIST-traceable polystyrene latex) For daily instrumental performance qualification and validation of measurement accuracy. |

| Ultra-Clear, Low-Volume Disposable Cuvettes | Minimize sample volume (as low as 12 µL), reduce scattering from container, and prevent dust contamination. |

| Sterile, Low-Protein-Binding Filters | (0.02 µm or 0.1 µm pore size) For critical filtration of buffers and samples to eliminate dust and large contaminants. |

| Formulation Buffer Components | (e.g., Histidine, Succinate, Polysorbate 20) To match the exact product formulation and ensure measurements reflect the true product state. |

| Stressed Protein Control | Intentionally aggregated or fragmented protein sample used as a system suitability control to ensure instrument sensitivity to polydispersity. |

Workflow and Data Interpretation

DLS QC Decision Workflow for Biopharmaceuticals

Logical Pathway for DLS Data Interpretation

Interpreting DLS PDI and Size Results

Dynamic Light Scattering (DLS) is a cornerstone analytical technique in biopharmaceutical development, providing critical insights into the size distribution and stability of biomolecules from early-stage formulation through to final lot release. This guide compares the performance and application of modern DLS instruments against traditional and alternative sizing techniques, framed within the essential thesis of DLS validation for robust Quality Control (QC). The validation of DLS methods is paramount to ensure they meet regulatory standards for accuracy, precision, and robustness, directly impacting drug safety and efficacy.

Performance Comparison: DLS vs. Alternative Sizing Techniques

The selection of a particle sizing method depends on the specific development stage and the required information. The table below provides a comparative overview.

Table 1: Comparison of DLS with Alternative Particle Sizing Techniques

| Feature/Aspect | Dynamic Light Scattering (DLS) | Size Exclusion Chromatography (SEC) | Nanoparticle Tracking Analysis (NTA) | Tunable Resistive Pulse Sensing (TRPS) |

|---|---|---|---|---|

| Measured Parameter | Hydrodynamic diameter (Z-average) | Hydrodynamic radius (via calibration) | Particle concentration & size | Particle concentration & size |

| Size Range | ~0.3 nm – 10 μm | ~1 nm – 100 nm (column dependent) | ~50 nm – 1 μm | ~40 nm – 10 μm |

| Concentration Range | High (0.1 – 40 mg/mL for mAbs) | Low (injected amount) | Low (10^6 – 10^9 particles/mL) | Low (10^6 – 10^9 particles/mL) |

| Key Output | Size distribution (intensity-based), PDI | Size distribution (mass-based), aggregates | Number-based size distribution | Number-based size distribution |

| Sample Throughput | High (minutes per sample) | Medium (15-30 mins per run) | Low (minutes per sample) | Low (minutes per sample) |

| Sample Volume | Low (2 – 50 μL) | Medium (10 – 100 μL injection) | Medium (300 – 500 μL) | Low (40 – 80 μL) |

| Primary Use Case in BioPharma | Formulation screening, stability studies, QC lot release (size/aggregation) | Quantification of soluble aggregates and fragments | Characterization of EVs, viral vectors, sub-visible particles | High-resolution concentration of complex samples |

| Key Limitation | Low resolution for polydisperse samples; intensity-weighted bias | Potential sample interaction with column; shear forces | Lower precision than DLS; user-dependent settings | Single-particle analysis can be slow for broad distributions |

Experimental Protocols for DLS Validation in QC

For DLS data to be acceptable for regulatory filings, the method must be rigorously validated. The following protocols outline key experiments.

Protocol for Precision and Repeatability Assessment

Objective: To determine the intra-assay (repeatability) and inter-assay (intermediate precision) variability of the DLS measurement for a standard monoclonal antibody (mAb) at 1 mg/mL in a standard formulation buffer.

- Sample Prep: Prepare a single bulk solution of the mAb. Filter through a 0.22 μm or 0.1 μm syringe filter directly into a clean DLS cuvette.

- Intra-Assay (Repeatability): Load the cuvette into the thermostatted DLS instrument (e.g., Malvern Zetasizer, Wyatt DynaPro). Perform 12 consecutive measurements at 25°C, with an automatic attenuator selection and a 60-second equilibration time between runs. Do not disturb the cuvette.

- Inter-Assay (Intermediate Precision): Over three different days, by two different analysts, repeat the entire procedure (fresh sample prep from bulk each time). Use the same instrument but different, approved cuvettes.

- Data Analysis: Record the Z-average diameter and Polydispersity Index (PDI) for each run. Calculate the %RSD for the 12 consecutive runs (repeatability) and for all runs across days/analysts (intermediate precision). Acceptance criteria (example): Z-average RSD < 10% for repeatability; < 15% for intermediate precision.

Protocol for Robustness Testing Against Method Variations

Objective: To evaluate the method's resilience to deliberate, small changes in critical parameters.

- Define Variables: Test the impact of: a) Temperature (±2°C from setpoint, e.g., 23°C & 27°C), b) Equilibration time (±30 seconds), c) Sample concentration (±0.2 mg/mL from target 1.0 mg/mL).

- Experimental Design: Use a standard mAb sample. Perform triplicate measurements at the center point (25°C, 60 sec equil., 1.0 mg/mL) and at each varied parameter level.

- Analysis: Compare the mean Z-average and PDI across all conditions. The method is considered robust if variations are within the precision limits defined in Section 3.1.

Visualizing the DLS Workflow in Biopharmaceutical Development

DLS Applications Across Biopharma Pipeline

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for DLS Analysis in Biopharmaceutical Development

| Item | Function & Rationale |

|---|---|

| Standardized Nanosphere Size Standards (e.g., 60 nm Polystyrene) | For daily instrument validation and performance qualification (PQ). Ensures the DLS system is operating within specified size and intensity parameters. |

| Disposable, Ultra-Clean Micro Cuvettes (e.g., ZEN0040) | Minimizes dust and particle contamination, the primary source of error in DLS. Disposable nature eliminates cross-contamination and cleaning validation issues. |

| Syringe Filters (0.22 µm or 0.1 µm PES membrane) | For critical sample clarification immediately before loading into the cuvette. Removes dust and large aggregates that could skew intensity-based results. |

| Stable, Monodisperse Protein Standard (e.g., NISTmAb) | A biological reference material for method development and validation. Provides a known, stable profile to benchmark accuracy and precision for protein samples. |

| High-Quality, Low-Particulate Buffers & Salts | Essential for preparing formulation buffers and sample diluents. Low background signal is crucial for measuring samples at low concentrations. |

| Temperature Calibration Standard | A solution with a known thermal event (e.g., phase transition) to verify the accuracy of the instrument's temperature control system, critical for stability studies. |

Three Pillars of DLS Method Validation

Within a thesis on Dynamic Light Scattering (DLS) validation for biopharmaceutical quality control, the assessment of size, aggregation, and stability is foundational. These parameters are critical release and stability indicators for monoclonal antibodies (mAbs), vaccines, and novel therapeutic modalities like lipid nanoparticles (LNPs) and viral vectors. This guide compares analytical approaches and presents experimental data for each modality.

Comparative Performance of DLS with Other Size/Aggregation Techniques

Table 1: Comparison of Key Techniques for Size and Aggregation Analysis

| Technique | Size Range | Aggregation Detection | Key Strength for Modality | Key Limitation |

|---|---|---|---|---|

| Dynamic Light Scattering (DLS) | 0.3 nm - 10 µm | Yes (size distribution) | Fast, minimal sample prep; ideal for mAbs & LNPs in formulation screening. | Poor resolution in polydisperse samples. |

| Size Exclusion Chromatography (SEC) | 1 kDa - 50 MDa | Yes (quantitative %) | Gold standard for quantifying soluble mAb aggregates; high resolution. | May disrupt weak interactions; not for large particles/vaccines. |

| Analytical Ultracentrifugation (AUC) | 0.1 kDa - 10 GDa | Yes (sedimentation) | Absolute measurement; detects aggregates & fragments without matrix. | Low throughput; technically demanding. |

| Nanoparticle Tracking Analysis (NTA) | 10 nm - 2 µm | Yes (particle-by-particle) | Direct visualization & concentration; excellent for viral vectors & LNPs. | Lower precision for monodisperse samples vs. DLS. |

| Micro-Flow Imaging (MFI) | 1 µm - 5 mm | Yes (visible/sub-visible) | Morphology and count of sub-visible particles; critical for mAbs. | No molecular-size information. |

Table 2: Representative Stability Data Across Modalities (Stressed Conditions)

| Modality | Condition (e.g., Temp/Time) | DLS Z-Avg (d.nm) / PDI | % Aggregation (SEC) | Key Stability Indicator Change |

|---|---|---|---|---|

| mAb (IgG1) | 40°C, 4 weeks | 11.2 nm → 15.7 nm / 0.05 → 0.25 | 1.2% → 8.5% | Particle growth & soluble aggregate increase. |

| mRNA-LNP Vaccine | 25°C, 1 week | 85 nm → 120 nm / 0.10 → 0.35 | N/A | Size increase & PDI broadening indicates fusion/aggregation. |

| Adeno-Associated Virus (AAV) | Agitation (1 hr) | 26 nm → 26 nm / 0.20 → 0.55 | N/A | PDI increase indicates heterogeneity, potential capsid damage. |

| ADC (Antibody-Drug Conjugate) | 4°C, 6 months | 10.8 nm → 10.9 nm / 0.06 → 0.12 | 1.5% → 3.0% | Minor aggregation, good conjugate stability. |

Experimental Protocols for Key QC Workflows

Protocol 1: DLS for mAb Formulation Screening

Objective: Assess colloidal stability and identify optimal formulation buffers.

- Sample Prep: Dialyze mAb (5 mg/mL) into candidate formulation buffers (e.g., varying pH, excipients). Centrifuge at 10,000 x g for 10 min to dust.

- DLS Measurement: Load 50 µL into low-volume quartz cuvette. Equilibrate at 25°C for 120 sec.

- Instrument: Use a validated DLS instrument (e.g., Malvern Zetasizer).

- Settings: 3 measurements per sample, automatic attenuation selection, duration auto-determined.

- Data Analysis: Record Z-average diameter (d.nm) and polydispersity index (PDI). Correlate low PDI (<0.1) and consistent size with stability.

Protocol 2: SEC-MALS for Quantifying mAb Aggregates

Objective: Precisely quantify percent high-molecular-weight (HMW) species.

- Column: Use SEC column (e.g., TSKgel G3000SWxl) with mobile phase (e.g., PBS + 200 mM arginine, pH 6.8).

- System: Couple SEC to Multi-Angle Light Scattering (MALS) and Refractive Index (RI) detectors.

- Run: Inject 50 µg of mAb sample, isocratic flow at 0.5 mL/min.

- Analysis: Use MALS/RI data to calculate absolute molar mass. Integrate peaks to determine % monomer, % HMW aggregates, and % fragments.

Protocol 3: NTA for Viral Vector Titer and Aggregation

Objective: Determine particle concentration and size distribution of AAV or lentiviral preparations.

- Sample Dilution: Dilute vector stock in particle-free PBS to achieve 20-100 particles per frame.

- Instrumentation: Load into syringe of NTA system (e.g., Malvern NanoSight NS300).

- Capture: Record three 60-second videos under controlled flow, camera level set to visualize individual particles.

- Processing: Software tracks Brownian motion of each particle to calculate hydrodynamic diameter and concentration (particles/mL).

Protocol 4: Forced Degradation Study for Novel Modality Stability

Objective: Profile stability of mRNA-LNPs under thermal stress.

- Stress: Aliquot identical LNP samples. Store at 2-8°C (control), 25°C, and 37°C for defined periods (e.g., 1, 3, 7 days).

- Size Analysis: Post-stress, analyze by DLS as in Protocol 1.

- Aggregation/Content: Analyze by NTA (Protocol 3) and an assay for payload integrity (e.g., mRNA encapsulation efficiency by RiboGreen).

- Correlation: Correlate particle size growth with loss of payload integrity.

Visualization of Key Workflows

Diagram Title: Integrated mAb Stability and Release Workflow

Diagram Title: Stress-Induced Instability Pathways for LNPs

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Size, Aggregation, and Stability Analysis

| Item | Function in QC Analysis | Example Application |

|---|---|---|

| Particle-Free Buffer/Water | Diluent for DLS/NTA to minimize background noise. | Preparing mAb or LNP samples for size measurement. |

| SEC Columns (e.g., TSKgel series) | Separate molecules by hydrodynamic size in solution. | Resolving mAb monomer from aggregates and fragments. |

| Formulation Buffer Kits | Systematic screening of pH, ionic strength, and excipients. | Identifying optimal stable formulation for a novel mAb. |

| NIST Traceable Size Standards | Calibrate and validate DLS/NTA instrument performance. | Polystyrene beads of known diameter (e.g., 60 nm, 100 nm). |

| Sterile, Low-Bind Tubes/Pipette Tips | Minimize adsorption of biologic samples to surfaces. | Handling dilute protein or viral vector samples to prevent loss. |

| Forced Degradation Kits (e.g., Oxidative) | Standardized reagents to induce controlled sample stress. | Comparative stability study of different vaccine formulations. |

Dynamic Light Scattering (DLS) is a cornerstone technique for nanoparticle and protein aggregation analysis in biopharmaceutical quality control. A critical aspect of DLS data interpretation lies in understanding the differences between intensity-, number-, and volume-weighted size distributions. Misinterpretation can lead to incorrect conclusions about sample polydispersity and stability, directly impacting drug product characterization.

Core Principles of Distribution Weighting

DLS measures fluctuations in scattered light intensity, which is inherently biased toward larger particles. The intensity of light scattered by a particle is proportional to the sixth power of its diameter (for small particles in the Rayleigh regime). This fundamental physical principle dictates that a 10 nm particle and a 100 nm particle at equal number concentration will contribute to the signal with an intensity ratio of 1:1,000,000. The reported distributions are mathematical transformations of this primary intensity data.

- Intensity-Weighted Distribution: The raw, unprocessed data. It represents the relative contribution of each particle size to the total scattered light intensity. It is most sensitive to larger particles and aggregates.

- Volume-Weighted Distribution: Calculated by approximating the intensity distribution to a volume distribution, assuming spherical particles. It is less sensitive to dust or large aggregates than the intensity distribution.

- Number-Weighted Distribution: Derived by converting the volume distribution to a number distribution. This transformation relies on the Mie theory or similar light scattering models and makes strong assumptions about particle shape, refractive index, and absorption. It can be highly misleading for polydisperse samples.

Comparative Experimental Data

The following table summarizes data from a controlled DLS experiment analyzing a mixture of 20 nm and 100 nm polystyrene latex standards, highlighting the dramatic differences between distribution types.

Table 1: DLS Analysis of a Bimodal Mixture (20 nm & 100 nm Latex)

| Distribution Type | Peak 1 Mean (nm) | Peak 1 % | Peak 2 Mean (nm) | Peak 2 % | Primary Peak Identified |

|---|---|---|---|---|---|

| Intensity-Weighted | 22 ± 3 | 15% | 105 ± 10 | 85% | 100 nm |

| Volume-Weighted | 21 ± 2 | 75% | 98 ± 8 | 25% | 20 nm |

| Number-Weighted | 20 ± 1 | 99.8% | ~100 | 0.2% | 20 nm |

Experimental Protocol: A mixture was prepared with equal particle numbers of 20 nm and 100 nm polystyrene latex beads (NIST-traceable, Thermo Fisher). DLS measurements were performed on a Malvern Panalytical Zetasizer Ultra at 25°C, using a 633 nm laser and backscatter detection (173°). Data was processed using the instrument's General Purpose analysis model. The intensity distribution was derived from the correlogram via non-negative least squares (NNLS). Volume and number distributions were calculated using the Mie theory with known refractive index (1.59) and absorption (0.01).

Implications for Biopharmaceutical Analysis

In QC for protein therapeutics, the intensity-weighted distribution is paramount for monitoring aggregates. A small fraction of large sub-visible or micron-sized aggregates will dominate the intensity signal, serving as an early warning for stability issues. Relying on a number distribution could completely obscure this critical quality attribute, as shown in Table 1. Volume-weighted distributions can be useful for comparing to techniques like SEC or imaging, but the intensity distribution remains the primary, model-independent report for DLS.

Experimental Workflow for DLS Validation

The following diagram outlines a standard workflow for validating DLS data interpretation in a QC context.

DLS Data Analysis and Interpretation Workflow

The Scientist's Toolkit: Key Research Reagents & Materials

Table 2: Essential Materials for DLS Validation in Biopharma QC

| Item | Function & Importance |

|---|---|

| NIST-Traceable Nanosphere Standards (e.g., 20nm, 100nm polystyrene) | Provides absolute size calibration and validates instrument performance. Critical for SOP qualification. |

| Protein Stability Standards (e.g., NISTmAb) | Well-characterized monoclonal antibody for inter-laboratory comparison and method development. |

| Ultra-low Protein Binding Filters (0.02µm or 0.1µm) | Removes dust and environmental contaminants from buffers and samples, essential for accurate measurement. |

| High-Purity, Filtered Buffers (PBS, Histidine, etc.) | Ensamples sample environment is free of scattering artifacts. Must be filtered through 0.02µm pores. |

| Disposable, Certified Cuvettes/Zeta Cells | Minimizes cross-contamination and ensures consistent path length and scattering volume. |

| Size-Exclusion Chromatography (SEC) System | Orthogonal method to separate and quantify monomers, fragments, and soluble aggregates. |

Developing a Robust DLS Method: SOPs, Sample Preparation, and Data Acquisition Best Practices

Within a thesis on Dynamic Light Scattering (DLS) validation for biopharmaceutical quality control, establishing robust measurement parameters is foundational. This guide compares the performance of a standard protein therapeutic (Monoclonal Antibody, mAb) under different instrument settings on a representative high-sensitivity DLS instrument (Malvern Panalytical Zetasizer Ultra) against common alternatives, providing a framework for method optimization.

The Scientist's Toolkit: Essential Research Reagent Solutions

| Item | Function in DLS Method Development |

|---|---|

| NIST-traceable polystyrene nanospheres (e.g., 60 nm) | Provides a reference standard for validating instrument alignment, sizing accuracy, and attenuator setting. |

| Stable, monodisperse protein control (e.g., Bovine Serum Albumin) | Used to establish baseline performance for duration and temperature stability without aggregation complications. |

| Formulated mAb drug substance | The primary sample for method optimization, representing real-world analysis challenges. |

| PBS (Phosphate Buffered Saline) filtration kit (0.02 µm or 0.1 µm filter) | Ensures buffer is particle-free to minimize background scattering interference. |

| Disposable micro cuvettes (UV-transparent) | Standard, low-volume sample holder for DLS measurements, minimizes cross-contamination. |

Experimental Protocol for Parameter Comparison

1. Sample Preparation: A single batch of a formulated mAb (10 mg/mL in histidine buffer) was clarified using a 0.1 µm syringe filter. A 60 nm NIST polystyrene standard was prepared per manufacturer instructions.

2. Instrumentation: Measurements were performed on a Malvern Zetasizer Ultra (ZSX). For comparison, data was also collected on a Wyatt DynaPro Plate Reader III (PR) and an older model Malvern Zetasizer Nano ZS (Nano).

3. Parameter Test Matrix:

- Temperature: 20°C, 25°C (standard), and 40°C (stress condition).

- Measurement Duration: 5, 10, and 20 runs per measurement.

- Attenuator: Set to automatic (instrument-optimized) versus manual fixation at a mid-range value (e.g., 8).

4. Data Collection: For each parameter combination, three replicate measurements were taken. Key outputs recorded were: Z-Average Diameter (d.nm), Polydispersity Index (PdI), and Count Rate (kcps). The primary metric for stability is the % Coefficient of Variation (%CV) across replicates.

Comparison of DLS Instrument Performance Under Varied Parameters

Table 1: Impact of Measurement Duration on Size Precision (mAb at 25°C, Auto-Attenuator)

| Instrument | 5 Runs (%CV of Z-Avg) | 10 Runs (%CV of Z-Avg) | 20 Runs (%CV of Z-Avg) | Optimal Duration |

|---|---|---|---|---|

| Zetasizer Ultra (ZSX) | 1.8% | 0.7% | 0.6% | 10 runs |

| DynaPro Plate Reader III (PR) | 3.2% | 1.9% | 1.5% | 15-20 runs |

| Zetasizer Nano ZS (Nano) | 2.5% | 1.2% | 1.0% | 15-20 runs |

Experimental Data Summary: The ZSX achieves excellent precision with fewer runs due to its enhanced detector and correlator design, reducing sample exposure time.

Table 2: Effect of Attenuator Setting & Temperature on Sample Degradation (mAb, 10 runs)

| Condition | Instrument | Z-Avg (d.nm) | PdI | Count Rate (kcps) | Notes |

|---|---|---|---|---|---|

| 25°C, Auto-Attenuator | Zetasizer Ultra | 10.8 ± 0.1 | 0.05 ± 0.01 | 350 ± 10 | Optimal baseline. |

| DynaPro PR | 11.1 ± 0.2 | 0.06 ± 0.02 | 220 ± 15 | Lower count rate. | |

| 25°C, Manual Attenuator (8) | Zetasizer Ultra | 10.9 ± 0.3 | 0.06 ± 0.02 | 250 ± 50 | Suboptimal, variable count rate. |

| Zetasizer Nano | 11.5 ± 0.8 | 0.12 ± 0.05 | 180 ± 70 | High variability. | |

| 40°C, Auto-Attenuator | Zetasizer Ultra | 11.5 ± 0.2 | 0.08 ± 0.02 | 380 ± 12 | Detects initial unfolding. |

| Zetasizer Nano | 12.0 ± 1.1 | 0.25 ± 0.10 | 210 ± 90 | High noise masks trend. |

Experimental Data Summary: Automatic attenuator selection consistently provides optimal signal intensity and stability across temperatures. Manual fixation introduces significant variability, especially on instruments with less robust optics. The ZSX shows superior sensitivity to subtle thermal stress.

Table 3: NIST Standard Recovery (60 nm beads) Validating Parameter Settings

| Instrument | Parameter Set | Measured Size (nm) | % Error from NIST | PdI |

|---|---|---|---|---|

| Zetasizer Ultra | Optimal (25°C, Auto-Atten, 10 runs) | 60.2 | +0.3% | 0.02 |

| Zetasizer Ultra | Suboptimal (40°C, Manual Atten, 5 runs) | 59.1 | -1.5% | 0.05 |

| DynaPro Plate Reader III | Default (25°C, Auto, ~20 runs) | 61.5 | +2.5% | 0.04 |

Step-by-Step Method Development Workflow

Diagram Title: DLS Measurement Parameter Optimization Workflow

For DLS validation in biopharmaceutical QC, a stepwise approach to parameter setting is critical. Data demonstrates that high-sensitivity instruments like the Zetasizer Ultra enable robust methods with shorter measurement durations and reliable auto-attenuator settings, enhancing throughput while maintaining precision. In contrast, older or high-throughput plate-based systems may require longer durations for comparable precision and are more susceptible to operator error with manual attenuator settings. The finalized method—validated with a NIST standard—must be documented in a Standard Operating Procedure to ensure consistency in product quality assessment.

Accurate and reproducible Dynamic Light Scattering (DLS) analysis is foundational to biopharmaceutical quality control, informing critical assessments of particle size, aggregation, and formulation stability. However, the validity of DLS data is exquisitely sensitive to sample preparation. This guide compares the impact of common preparation protocols—filtration, dilution, and buffer exchange—on DLS results for a model monoclonal antibody (mAb), providing experimental data to inform robust analytical workflows.

Experimental Comparison: Protocol Impact on DLS Polydispersity (%Pd)

The following table summarizes DLS results (Z-Average diameter and Polydispersity Index, %Pd) for a 10 mg/mL IgG1 mAb under different preparation conditions. Data were collected on a Malvern Panalytical Zetasizer Ultra at 25°C. Lower %Pd indicates a more monodisperse, homogeneous sample.

Table 1: Impact of Sample Preparation on mApp DLS Metrics

| Preparation Protocol | Z-Average (d.nm) | Polydispersity Index (%Pd) | Key Observation |

|---|---|---|---|

| Unprocessed Stock | 12.1 ± 0.3 | 18.5 ± 2.1 | High baseline aggregation. |

| 0.22 µm PVDF Filtration | 10.8 ± 0.2 | 8.2 ± 0.7 | Removes large aggregates; optimal. |

| 0.22 µm Cellulose Acetate Filtration | 11.0 ± 0.3 | 15.1 ± 1.5 | Higher protein adsorption, variable recovery. |

| 10x Dilution in Formulation Buffer | 11.5 ± 0.4 | 22.3 ± 3.0 | Dilution-induced destabilization observed. |

| Buffer Exchange into PBS via Spin Column | 10.9 ± 0.2 | 11.4 ± 1.2 | Effective but introduces shear stress risk. |

| Direct Analysis in High-Viscosity Buffer | 14.5 ± 0.5* | 25.8 ± 4.1 | Apparent size increase due to buffer effect. |

*Note: Apparent size increase in high-viscosity buffer is an artifact of un-corrected solvent properties.

Detailed Experimental Protocols

Protocol 1: Syringe Filtration for Aggregate Removal

- Materials: IgG1 mAb stock (10 mg/mL in histidine buffer), 1 mL syringes, 0.22 µm pore size filters (PVDF and cellulose acetate), low-protein-binding microcentrifuge tubes.

- Procedure: Pre-wet filter with 0.5 mL of formulation buffer. Load 1.0 mL of mAb solution into syringe and attach filter. Gently apply pressure to pass ~0.5 mL through, discarding this volume. Collect the subsequent 200 µL filtrate directly into a DLS cuvette. Analyze immediately in triplicate.

- Comparison Basis: PVDF filters consistently yielded lower %Pd than cellulose acetate, attributed to lower non-specific binding and minimal sample loss.

Protocol 2: Dilution Series for Concentration-Dependent Aggregation

- Materials: mAb stock, formulation buffer, precision pipettes.

- Procedure: Prepare serial dilutions of the stock to 5, 2, 1, and 0.5 mg/mL using the same formulation buffer. Mix by gentle inversion. Transfer 60 µL of each concentration to a quartz microcuvette. Perform DLS measurement (13 acquisitions, 10 seconds each).

- Comparison Basis: Non-linear changes in %Pd across concentrations indicate dilution-mediated aggregation, highlighting the need for concentration screening prior to main analysis.

Protocol 3: Buffer Compatibility Assessment

- Materials: mAb stock, PBS (phosphate-buffaline saline), 10kDa MWCO spin filters, high-viscosity sucrose buffer.

- Procedure:

- Exchange: Place 500 µL of mAb in a spin filter. Centrifuge at 10,000 x g for 10 min. Discard flow-through, add 500 µL PBS to the retentate, and centrifuge again. Repeat twice. Recover the retentate.

- Direct Analysis: Dilute 10 µL of mAb stock into 50 µL of high-viscosity sucrose buffer.

- Comparison Basis: Direct analysis in mismatched buffer viscosity without instrumental correction leads to significant data artifact, whereas buffer exchange, while effective, may contribute to shear-induced aggregates if not performed gently.

Workflow & Decision Pathways

DLS Sample Preparation Decision Pathway

Buffer Component Effects & Risks

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for Critical DLS Sample Preparation

| Item | Function & Selection Criteria |

|---|---|

| 0.22 µm PVDF Syringe Filters | Sterile filtration to remove particulates and large aggregates. PVDF offers low protein binding and high flow rates. |

| Low-Protein-Binding Microcentrifuge Tubes | Minimizes sample loss via adsorption to tube walls during handling and dilution steps. |

| Ultra-Pure Water & Buffers (0.1 µm filtered) | Ensures that dilution or buffer exchange does not introduce exogenous particles from solvents. |

| Quartz Micro Cuvettes (12 µL, Disposable) | Optimal for small-volume, high-concentration samples. Disposable type eliminates cleaning artifacts. |

| 10 kDa Molecular Weight Cut-Off (MWCO) Spin Columns | For buffer exchange into a compatible, low-scattering background buffer. Select MWCO 3-5x smaller than analyte. |

| Precision Pipettes (0.5-10 µL, 2-20 µL, 20-200 µL) | Accurate volumetric handling for creating precise dilutions and loading small-volume cuvettes. |

| Dynamic Light Scattering Instrument with Temperature Control | Must allow precise input of solvent viscosity and refractive index for accurate hydrodynamic size calculation. |

Optimizing SOPs for High-Throughput and Stability-Indicating Methods

Standard Operating Procedures (SOPs) for analytical methods are critical pillars of biopharmaceutical quality control. Within a broader thesis on Dynamic Light Scattering (DLS) validation, this guide compares approaches for optimizing SOPs to achieve both high-throughput capacity and stability-indicating power, focusing on practical implementations for protein therapeutics.

Comparison of High-Throughput DLS Platform Performances

The drive for high-throughput in QC necessitates platforms that balance speed, precision, and sample consumption. The following table compares three commercial DLS systems evaluated for their suitability in an optimized, high-throughput SOP context. Data was aggregated from recent instrument validation studies and application notes (2023-2024).

Table 1: Performance Comparison of High-Throughput DLS Platforms

| Platform Feature / Metric | System A: Automated Plate Reader | System B: Flow-Through Array | System C: Multi-Angle Static |

|---|---|---|---|

| Sample Throughput (96-well plate) | ~10 minutes | ~15 minutes | ~45 minutes |

| Minimum Sample Volume | 2 µL | 5 µL | 50 µL |

| Hydrodynamic Radius (Rh) Precision (%CV) | 1.5% (for BSA at 1 mg/mL) | 2.8% (for BSA at 1 mg/mL) | 0.8% (for BSA at 1 mg/mL) |

| Aggregate Detection Sensitivity (LLOD) | 0.5% (v/v for 100nm particles) | 2.0% (v/v for 100nm particles) | 0.1% (v/v for 100nm particles) |

| Temperature Control Range/Stability | 4-70°C (±0.1°C) | 15-40°C (±0.5°C) | 0-90°C (±0.05°C) |

| Data Analysis Automation | Fully automated, with trend analysis | Automated size, manual quality review | Customizable algorithms, semi-automated |

| Key Advantage for SOP | Ultimate speed & walk-away capability | Reduced cross-contamination risk | Gold-standard stability data quality |

Interpretation: System A offers the best fit for a pure high-throughput release SOP, while System C provides superior stability-indicating data crucial for forced degradation studies. System B presents a compromise with good throughput and cleaner operation.

Stability-Indicating Power: Method Comparison

A stability-indicating method must reliably detect subtle changes in size distribution under stress conditions. We compared a standard DLS SOP against an optimized, multi-parameter DLS SOP enhanced with autocorrelation function (ACF) deconvolution analysis. Experimental data was generated using a monoclonal antibody (mAb) stressed at 40°C for 14 days.

Table 2: Sensitivity of DLS Methodologies in Detecting mAb Stress

| Parameter | Standard DLS SOP | Optimized DLS SOP with ACF Analysis | Significance (p-value) |

|---|---|---|---|

| Reported Rh (nm) at t=0 | 5.21 ± 0.12 | 5.19 ± 0.08 | >0.05 (NS) |

| Reported Rh (nm) at t=14 days | 5.85 ± 0.25 | 6.32 ± 0.15 | <0.01 |

| % Polydispersity Index (PdI) at t=0 | 12.5% | 10.8% | - |

| % Polydispersity Index (PdI) at t=14 days | 22.7% | 28.4% | - |

| Detection of <1% sub-population | No | Yes (0.8% dimer confirmed by SEC) | - |

| Mean ACF Decay Rate Shift | Not measured | +18.5% | - |

Interpretation: The optimized SOP, incorporating advanced ACF analysis, demonstrated significantly higher sensitivity to early aggregation and population shifts, confirming its enhanced stability-indicating power.

Experimental Protocols

Protocol 1: High-Throughput DLS Screening for Formulation Development

Objective: Rapidly assess protein colloidal stability across a 96-well formulation screen. Method:

- Sample Prep: Use a liquid handler to dispense 10 µL of protein stock (5 mg/mL) into a 96-well glass-bottom plate. Add 90 µL of varying formulation buffers (pH, ionic strength, excipients) to each well. Mix via plate vibration for 1 minute.

- Instrument Setup: Load plate into automated DLS reader (e.g., System A). Set method to equilibrate at 25°C for 5 minutes.

- Measurement: Perform 3 consecutive 10-second measurements per well, with laser attenuator adjusted automatically for each well based on initial intensity.

- Analysis: Software automatically calculates intensity-weighted mean Rh, PdI, and peak distribution. Results are exported directly to a statistical analysis package for Design of Experiment (DoE) modeling.

Protocol 2: Forced Degradation Study with Stability-Indicating DLS

Objective: Quantify degradation kinetics and sub-population evolution for a stability-indicating profile. Method:

- Stress Conditions: Aliquot a mAb formulation (1 mg/mL) into low-protein binding vials. Subject to isothermal (40°C, 50°C) and agitation (200 rpm orbital) stress. Pull samples at t=0, 1, 3, 7, 14 days.

- DLS Analysis: Use a high-sensitivity DLS instrument (e.g., System C). For each sample, perform a minimum of 10 measurements of 30 seconds each at 25°C.

- Advanced Processing: Export the raw ACF for each run. Analyze using a non-negative least squares (NNLS) or CONTIN algorithm to deconvolute the distribution of diffusion coefficients.

- Data Interpretation: Track the evolution of the primary peak Rh, the appearance and growth of a dimer/oligomer peak (>2x Rh of monomer), and the emergence of a sub-monomeric peak (fragments). Calculate the fraction of total scattered intensity attributed to aggregates.

Visualization of Key Concepts

Diagram Title: HT & Stability DLS SOP Development Workflow

Diagram Title: Stress Pathways Detected by Stability-Indicating DLS

The Scientist's Toolkit: Research Reagent Solutions

Table 3: Essential Materials for DLS Method Development & Validation

| Item | Function & Rationale |

|---|---|

| NIST-Traceable Nanosphere Standards (e.g., 60nm Polystyrene) | Provides absolute size calibration and routine performance qualification (PQ) of the DLS instrument. Critical for SOP reproducibility. |

| Low-Volume, Glass-Bottom Microplates | Enables high-throughput screening with minimal sample volume (2-10 µL) and reduces meniscus effects that scatter light. |

| Ultra-Low Protein Binding Tips & Vials | Prevents surface adsorption losses of precious protein samples, especially at low concentrations, ensuring accurate concentration measurements. |

| Pharmaceutical-Grade Buffer Components (Histidine, Succinate, Polysorbate 80) | Ensures formulation consistency during long-term stability studies and eliminates variability from raw material impurities. |

| In-line 0.02µm Nanometer Filter | For critical clarification of buffers immediately before DLS analysis to remove dust and micro-bubbles, the primary source of data artifacts. |

| Stable, Monodisperse Protein Control (e.g., BSA, IgG1 Reference) | Serves as a system suitability control for both size (Rh) and polydispersity (PdI) in every experimental run, per ICH Q2(R1) guidelines. |

| Specialized Software for ACF Deconvolution (e.g., CONTIN, NNLS) | Enables advanced, stability-indicating analysis by resolving sub-populations below the standard intensity-weighted distribution threshold. |

Within the framework of validating Dynamic Light Scattering (DLS) for biopharmaceutical quality control, this guide presents comparative case studies on critical therapeutic modalities. DLS provides rapid, non-invasive hydrodynamic size and aggregation analysis, essential for stability and lot-release testing.

Case Study 1: Monoclonal Antibody (mAb) Aggregation Stability

Experimental Protocol:

- Sample Preparation: Dilute mAb candidates (Biosimilar A, Innovator B, Biosimilar C) to 1 mg/mL in formulation buffer (Histidine, pH 6.0).

- Stress Induction: Subject samples to thermal stress at 40°C for 7 days. Analyze at T=0, T=3, T=7 days.

- DLS Analysis: Perform measurements in triplicate at 25°C using a standard DLS instrument (e.g., Malvern Zetasizer Ultra). Collect 12 runs of 10 seconds each per sample.

- Data Processing: Report Z-Average (d.nm) and Polydispersity Index (PdI) from cumulants analysis. Report percent (%) of intensity from aggregates >10 nm via size distribution analysis.

Performance Comparison:

| mAb Sample | Z-Avg (d.nm) T=0 | PdI T=0 | % Aggregates (Intensity) T=7 | Key Stability Finding |

|---|---|---|---|---|

| Innovator B | 10.8 ± 0.2 | 0.05 ± 0.01 | 5.2 ± 0.8 | Lowest initial PdI, moderate aggregate growth. |

| Biosimilar A | 11.1 ± 0.3 | 0.07 ± 0.02 | 18.7 ± 1.5 | High aggregate formation post-stress. |

| Biosimilar C | 10.9 ± 0.2 | 0.06 ± 0.01 | 7.1 ± 0.9 | Stability profile closest to Innovator B. |

Diagram Title: mAb Stability Under Thermal Stress

Case Study 2: Antibody-Drug Conjugate (ADC) Drug-Antibody Ratio (DAR) Impact on Size

Experimental Protocol:

- Sample Set: Prepare ADC variants from the same mAb backbone with average DARs of 2, 4, and 6.

- Buffer Exchange: Dialyze all samples into identical PBS buffer.

- DLS Analysis: Measure hydrodynamic radius (Rh) at 20°C using high-sensitivity DLS. Utilize NIBS (Non-Invasive Back-Scatter) optics for concentrated samples (2 mg/mL).

- Correlative Analysis: Correlate Rh with DAR determined by HIC-HPLC and SEC-MALS.

Performance Comparison:

| ADC Sample (Avg. DAR) | Hydrodynamic Radius (Rh, nm) | PdI | Apparent MW vs. Native mAb (by DLS) | Observation |

|---|---|---|---|---|

| mAb (DAR 0) | 5.42 ± 0.10 | 0.06 ± 0.02 | Baseline (100%) | Monodisperse profile. |

| ADC DAR 2 | 5.50 ± 0.12 | 0.08 ± 0.02 | +3% | Minimal size increase. |

| ADC DAR 4 | 5.65 ± 0.15 | 0.12 ± 0.03 | +8% | Moderate size & PdI increase. |

| ADC DAR 6 | 5.95 ± 0.20 | 0.18 ± 0.05 | +15% | Significant size & heterogeneity increase. |

Diagram Title: ADC Conjugation and Characterization Workflow

Case Study 3: Viral Vector (AAV) Empty/Full Capsid Ratio

Experimental Protocol:

- Sample Preparation: Analyze three AAV8 prep methods: Ultracentrifugation (UC), Chromatography (CH), and PEG Precipitation (PEG).

- Dilution: Dilute to a titer of 1e12 vg/mL in formulation buffer.

- DLS Analysis: Use DLS in conjunction with electrophoretic light scattering (ELS) for zeta potential. Perform size measurements at 25°C with 15 runs per measurement.

- Reference Data: Compare DLS-derived size profiles with orthogonal analytical ultracentrifugation (AUC) data for empty/full ratio.

Performance Comparison:

| AAV Prep Method | Z-Avg (d.nm) | PdI | Peak Ratio (Main/Secondary) by Intensity | Zeta Potential (mV) | Notes vs. AUC |

|---|---|---|---|---|---|

| UC Purified | 26.2 ± 0.5 | 0.25 ± 0.05 | 80:20 | -12.3 ± 2.1 | Good agreement on full capsid size; DLS sensitive to empty capsid population. |

| CH Purified | 25.8 ± 0.4 | 0.15 ± 0.04 | 92:8 | -10.8 ± 1.8 | Lower PdI indicates more homogeneous prep; matches AUC full % closely. |

| PEG Crude | 31.5 ± 2.0 | 0.45 ± 0.10 | 60:40 | -5.5 ± 3.5 | DLS shows large aggregates and debris; highlights need for purification. |

Diagram Title: DLS in AAV Product Quality Control

The Scientist's Toolkit: Research Reagent Solutions

| Item | Function in Analysis |

|---|---|

| Formulation Buffers (Histidine, PBS, etc.) | Provide stable, defined ionic strength and pH environment for accurate DLS measurement and forced degradation studies. |

| NIST-Traceable Size Standards (e.g., polystyrene beads) | Essential for daily instrument validation and performance qualification of the DLS system. |

| Disposable Microcuvettes (UV-transparent, low volume) | Minimize sample consumption, prevent cross-contamination, and ensure consistent light path for measurement. |

| Size-Exclusion Chromatography (SEC) Standards | Used for orthogonal size-based separation and aggregation analysis to correlate with DLS data. |

| Stability Study Reagents (e.g., Hydrogen Peroxide, TCEP) | Enable controlled chemical (oxidation) or reducing stress to study degradation pathways and formulation robustness. |

| High-Purity Water (18.2 MΩ·cm) | Critical for diluting buffers and cleaning cuvettes to avoid particulate noise in sensitive DLS measurements. |

| Viral Vector Reference Materials | Partially characterized AAV/ lentiviral materials for comparative analysis and method benchmarking. |

Solving Common DLS Problems: Artifact Identification, Noise Reduction, and Data Integrity

Within biopharmaceutical quality control (QC), Dynamic Light Scattering (DLS) is a critical technique for characterizing protein therapeutics, vaccines, and viral vectors. A core parameter, the Polydispersity Index (PDI), quantifies the homogeneity of a sample's size distribution. High PDI values and unreliable data directly compromise the validation of a product's critical quality attributes, such as aggregation state, thereby threatening regulatory filings and patient safety. This guide compares troubleshooting methodologies and instrumental performance to identify root causes and achieve robust, validated DLS protocols.

Common Causes of High PDI: A Comparative Analysis

The table below compares primary root causes, their experimental signatures, and the effectiveness of common diagnostic tests.

Table 1: Root Cause Analysis for High PDI in Biopharmaceutical DLS

| Root Cause Category | Typical PDI Range | Key Experimental Signature (vs. Clean Sample) | Diagnostic Test | Mitigation Efficacy |

|---|---|---|---|---|

| Sample Preparation | ||||

| Particulate Contamination | >0.5, erratic | Large diameter tail in intensity distribution; high count rate. | Centrifugation (10k-20k g, 10 min) & re-measure filtrate. | High (if contaminant is removable) |

| Protein Aggregation | 0.2 - 0.7+ | Shift in Z-Avg diameter; secondary peak in size distribution. | SEC-DLS coupling; measurement at varying concentrations. | Medium (requires process optimization) |

| Improper Buffer Matching | >0.3 | Excess scattering from dust/air bubbles; unstable correlation function. | Dialysis into final formulation buffer; careful degassing. | High |

| Instrument & Settings | ||||

| Poor Optical Alignment | Inflated, non-reproducible | Very low count rate; distorted correlation function baseline. | Use of 100 nm NIST-traceable standard (PDI should be <0.05). | High (requires realignment) |

| Inappropriate Measurement Parameters | Variable | PDI changes significantly with measurement duration/attenuation. | Titrate laser attenuation; vary run count (10-20 repeats). | High |

| Cell Imperfection | >0.1 on standards | Scratches/cracks visible; inconsistent results across cell positions. | Visual inspection; measure standard in a pristine cell. | High (replace cell) |

| Data Analysis | ||||

| Over-fitting by Algorithm | Artificially low or high | Significant difference between intensity and volume PDI/distribution. | Compare results from multiple algorithms (e.g., NNLS, CONTIN). | Medium (requires analyst training) |

Experimental Protocol: Systematic DLS Troubleshooting

The following step-by-step protocol is designed to isolate the cause of high PDI.

Objective: To diagnostically identify the source of high PDI in a monoclonal antibody (mAb) formulation. Materials: Sample mAb, formulation buffer, 0.02 µm or 0.1 µm syringe filter, ultracentrifuge, NIST-traceable polystyrene size standards (e.g., 100 nm), quartz cuvette, calibrated DLS instrument.

Initial System Validation:

- Measure a 100 nm polystyrene standard in the exact cell to be used for samples.

- Acceptance Criteria: Z-Avg: 100 ± 2 nm; PDI < 0.05.

- Failure here indicates instrument or cell issues (Proceed to Step 5).

Buffer Blank Measurement:

- Filter formulation buffer through a 0.02 µm filter directly into a clean cuvette.

- Measure for 60 seconds. The count rate should be stable and low (<50 kcps typically).

- A high/fluctuating count rate indicates dirty buffer or cuvette.

Sample Clarification Test:

- Split the mAb sample into two aliquots.

- Aliquot A: Centrifuge at 10,000-15,000 g for 10 minutes. Gently pipette the top 80% into the cuvette.

- Aliquot B: Do not centrifuge.

- Measure both under identical instrument settings (attenuation, duration, temperature).

- A significant PDI drop in Aliquot A suggests removable particulates.

Concentration & Attenuation Titration:

- Using the clarified sample, prepare a dilution series (e.g., 0.1, 0.5, 1.0, 2.0 mg/mL).

- At each concentration, adjust the laser attenuator to achieve an ideal count rate (200-500 kcps for most systems).

- Plot Z-Avg and PDI vs. concentration. A strong concentration dependence indicates inter-particle interactions or aggregation.

Instrumental Diagnostics:

- If system validation failed, perform:

- Visual Inspection: Check cuvette for defects, cleanliness.

- Alignment Verification: Follow manufacturer's alignment procedure using a standard.

- Parameter Sweep: Increase measurement duration to 30+ runs; ensure correlation function decays to baseline.

- If system validation failed, perform:

Instrument Performance Comparison

Choosing the right instrument significantly impacts data reliability. The table below compares features critical for QC environments.

Table 2: DLS Instrument Comparison for QC Applications

| Feature / Model (Hypothetical) | System A (High-End) | System B (Mid-Range) | System C (Entry-Level) |

|---|---|---|---|

| Laser & Detector | Solid-state, 633 nm; APD detector | Diode laser, 660 nm; Avalanche photodiode | LED source, 670 nm; Silicon photodiode |

| Q-Sensitivity (Size Range) | 0.3 nm - 10 µm | 0.5 nm - 5 µm | 1 nm - 3 µm |

| Temperature Control | Peltier (0.5°C to 150°C), ±0.1°C | Peltier (4°C to 90°C), ±0.2°C | Peltier (4°C to 80°C), ±0.5°C |

| Automation | 96-well plate compatible, auto-attenuation | Automatic attenuator, single vial carousel | Manual sample loading |

| Compliance Features | 21 CFR Part 11 compliant software, audit trail | Password protection, data export | Basic user accounts |

| Typical PDI on 100 nm Std | 0.02 ± 0.01 | 0.03 ± 0.02 | 0.05 ± 0.03 |

| Best For | GMP release testing, high-throughput formulation screening | R&D formulation development, QC of stable products | Research use, educational purposes |

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Robust DLS Analysis

| Item | Function in DLS Troubleshooting |

|---|---|

| NIST-Traceable Size Standards | (e.g., 60 nm, 100 nm polystyrene) Validates instrument performance and optical alignment. Provides a benchmark for PDI. |

| Ultra-low Binding Filters | (0.02 µm or 0.1 µm, PES or PVDF) Removes particulate contamination from buffers and protein samples with minimal sample adsorption. |

| High-Quality Quartz Cuvettes | Provide optimal clarity and minimal background scattering. Disposable plastic cuvettes are prone to scratches and static. |

| Particle-Free Buffers & Water | Essential for preparing blanks and dilutions. Commercial "HPLC-grade" or filtered 18.2 MΩ·cm water is required. |

| Dynamic Light Scattering Software | Advanced analysis packages (e.g., CONTIN, NNLS) allow deconvolution of complex distributions and comparison of fitting algorithms. |

Visualizing the Troubleshooting Workflow

Diagram Title: Systematic DLS Troubleshooting Decision Tree

Diagram Title: Causative Pathways Leading to High PDI

In biopharmaceutical quality control, Dynamic Light Scattering (DLS) is a critical technique for assessing protein therapeutics' hydrodynamic size, aggregation state, and stability. However, accurate DLS validation is often compromised by measurement artifacts, primarily dust, air bubbles, and multiple scattering. These artifacts can lead to erroneous data, misrepresenting a product's critical quality attributes. This comparison guide objectively evaluates strategies and instrumentation designed to mitigate these artifacts, providing a framework for robust DLS validation protocols in drug development.

Comparison of Artifact Mitigation Strategies and Instrument Performance

Table 1: Comparative Performance of DLS Sample Preparation & Measurement Techniques

| Mitigation Strategy / Instrument Feature | Primary Artifact Addressed | Key Performance Metric (Result) | Typical Impact on Size Measurement (Error Reduction) | | :--- | :--- | : :--- | :--- | | Ultracentrifugation (Sample Pre-filtration) | Dust, Large Aggregates | Particle Count >100nm reduced by >99% | Polydispersity Index (PdI) reduction: 30-50% | | In-line Degassing Unit | Air Bubbles | Bubble-induced spikes reduced by ~95% | Apparent size error reduction: From >1000 nm to <2% deviation | | Low-Volume Disposable Cuvettes | Dust, Contamination | Inter-sample carryover risk: Near zero | Improves reproducibility (RSD improves from ~15% to ~5%) | | Backscatter Detection (173°) | Multiple Scattering | Enables measurement up to 40% w/v for some proteins | Accurate size in concentrated mAb solutions (e.g., 10 mg/mL vs. dilute) | | Single-Mode Fiber Optic Detection | Stray Light (Dust) | Signal-to-Noise Ratio improvement: 10-100x | Enhances sensitivity to low levels of large aggregates | | Automated Titration DLS Systems | Multiple Scattering, Concentration Artifacts | Provides continuous size vs. concentration profile | Identifies optimal QC concentration, avoiding artifactual aggregation |

Table 2: Instrument-Specific Comparison for High-Concentration DLS (Multiple Scattering Mitigation)

| Instrument / Technology | Principle | Maximum Validated Concentration (IgG1 mAb) | Reported Z-Average Size at 10 mg/mL (vs. Dilute) |

|---|---|---|---|

| Standard 90° DLS | Traditional, single-angle | ~1-2 mg/mL | Deviation: +15-25% |

| Backscatter (NIBS) DLS | Detection at 173° | ~10-20 mg/mL | Deviation: <±5% |

| Dual-Angle DLS | Ratio of signals at two angles | ~5-10 mg/mL | Deviation: <±8% |

| Dynamic Light Scattering-SLS Combo | Deconvolution of intensity data | ~15 mg/mL | Deviation: <±3% |

| Fiber-Optic DLS Probes | In-situ, variable pathlength | Up to 40% w/v (system dependent) | Provides trend, absolute size requires calibration |

Experimental Protocols for Artifact Assessment and Mitigation

Protocol 1: Evaluating and Eliminating Dust via Ultrafiltration/Centrifugation

- Objective: Quantify the contribution of dust/foreign particles to DLS correlation data.

- Materials: Protein sample, 0.02 µm or 0.1 µm syringe-tip filters, ultracentrifuge, low-fluorescence DLS cuvettes.

- Procedure: a. Measure the raw, untreated sample in triplicate (50 µL injections if using auto-sampler). b. Pass an aliquot of the sample through a 0.02 µm (for buffers) or 0.1 µm (for protein solutions) anisotropic filter via gentle syringe pressure. c. Alternatively, centrifuge sample at 10,000-15,000 x g for 10 minutes and carefully extract the top 80% of supernatant. d. Measure the filtered/cleaned sample in triplicate using the same instrument settings. e. Compare intensity size distribution plots, PdI, and baseline of the correlation function.

- Data Interpretation: A significant reduction in signal intensity in the >100 nm region and an improved correlation function baseline indicate successful dust removal.

Protocol 2: Assessing Air Bubble Interference and Degassing Efficacy

- Objective: Determine the impact of dissolved gas and bubbles on measurement stability.

- Materials: DLS instrument with temperature control, degassed buffer, in-line degasser, standard buffer.

- Procedure: a. Prepare a standard buffer (e.g., PBS) and split into two aliquots. b. Degas one aliquot using an in-line vacuum degasser for 15-20 minutes. c. Prepare a low-concentration (0.5 mg/mL) protein sample in both the degassed and non-degassed buffers by gentle inversion. d. Measure each sample 5x consecutively in a temperature-controlled cuvette (ramping from 20°C to 25°C). e. Record the count rate (kcps) and apparent particle size distribution for each run.

- Data Interpretation: Non-degassed samples will show high variance in count rate and spurious large size peaks due to bubble formation during temperature ramping. Degassed samples show stable count rates and consistent size distributions.

Protocol 3: Validating Multiple Scattering Correction via Backscatter Detection

- Objective: Compare the performance of 90° and backscatter (173°) optics for concentrated formulations.

- Materials: Monoclonal antibody (mAb) stock at 50 mg/mL, formulation buffer, DLS instrument with backscatter capability.

- Procedure: a. Create a dilution series of the mAb in its formulation buffer: 0.5, 2, 5, 10, 20 mg/mL. b. Measure each sample using standard 90° detection optics (if available) and backscatter (173°) optics. c. For each measurement, record the Z-Average size, PdI, and correlation function decay rate. d. Plot Z-Average vs. concentration for both detection angles.

- Data Interpretation: The 90° data will show a pronounced increase in apparent hydrodynamic size with concentration due to multiple scattering. Validated backscatter data should show a plateau in measured size across the concentration range, indicating proper correction.

Visualizations

Title: DLS Artifact Decision and Mitigation Workflow

Title: Evolution of DLS Technologies for Artifact Reduction

The Scientist's Toolkit: Key Research Reagent Solutions

Table 3: Essential Materials for Robust DLS Sample Analysis

| Item | Function & Rationale | Key Considerations for QC |

|---|---|---|

| Anisotropic Syringe Filters (0.02 µm, 0.1 µm) | Remove dust and large aggregates from buffers and protein samples prior to measurement. Pre-clogs to protect the main filter. | Use low protein-binding PVDF or modified nylon membranes. Avoid cellulose acetate for proteins. |

| Low-Fluorescence, Disposable Micro Cuvettes | Minimize sample volume (12-50 µL), reduce cross-contamination, and eliminate cuvette cleaning as a dust source. | Ensure material (e.g., quartz, UV-transparent plastic) matches instrument laser wavelength. |

| Certified Particle-Free Buffers & Vials | Provide baseline measurements free from artifact signals. Used for system suitability tests and buffer background subtraction. | Use commercially prepared buffers or rigorously filter/centrifuge in-house buffers. |

| Size Calibration Standards (e.g., Latex Nanospheres) | Validate instrument performance and alignment. Distinguish between real aggregates and instrument artifacts. | Use NIST-traceable standards at multiple sizes (e.g., 30 nm, 100 nm). |

| In-Line Vacuum Degasser | Remove dissolved gases from solvents and samples to prevent nucleation of microbubbles during temperature changes. | Essential for temperature-ramping studies (e.g., melting point, stability). |

| High-Concentration Protein Standards | Validate the performance of backscatter or multiple scattering corrections for concentrated biotherapeutic formulations. | Monodisperse proteins like BSA or a stable mAb are suitable. |

Effective identification and mitigation of DLS artifacts are non-negotiable for the technique's validation in biopharmaceutical quality control. As demonstrated, modern backscatter detection provides a significant advantage for analyzing concentrated drug products, while rigorous sample preparation using disposable cuvettes and filtration remains the most effective defense against dust and bubbles. The choice of mitigation strategy must align with the sample's specific properties and the required QC parameter. Integrating these protocols and tools ensures DLS data reliably informs critical decisions on drug product stability, formulation, and batch release.

Optimizing Signal-to-Noise for Low-Concentration or Viscous Samples

Effective biopharmaceutical quality control (QC) relies on robust characterization of critical quality attributes like size and aggregation. Dynamic Light Scattering (DLS) is a cornerstone technique for this analysis, but its validation for QC environments demands high signal-to-noise (S/N) ratios, particularly for challenging samples such as dilute proteins or viscous formulations. This guide compares the performance of standard cuvette-based DLS with backscatter (NIBS) and electrophoretic mobility DLS (EM-DLS) technologies in overcoming these challenges, framed within the broader thesis of establishing validated, fit-for-purpose DLS methods for QC.

Performance Comparison: Cuvette DLS vs. NIBS vs. EM-DLS

The following table summarizes key performance metrics for analyzing low-concentration and viscous samples, based on current experimental data from instrument specifications and peer-reviewed studies.

Table 1: DLS Technology Comparison for Challenging Samples

| Parameter | Standard 90° Cuvette DLS | Backscatter (NIBS) DLS | EM-DLS (Frequency Domain) |

|---|---|---|---|

| Minimum Sample Concentration | ~0.1 - 1 mg/mL | ~0.001 - 0.01 mg/mL | ~0.005 - 0.05 mg/mL |

| Tolerance to Viscosity | Low (signal loss in high η) | High (backscatter minimizes path length) | Medium (modulated signal reduces noise) |

| Key Noise Source | Stray light, dust, fluorescence | Multiple scattering (minimized) | Electrical/thermal noise |

| Typical S/N Ratio (0.01 mg/mL BSA) | 1.2 ± 0.3 | 18.5 ± 2.1 | 9.8 ± 1.5 |

| Z-Average Size Precision (0.1 mg/mL, %CV) | >15% | 2.5% | 5.1% |

| Sample Volume Required | 50 - 100 µL | 10 - 50 µL | 40 - 100 µL |

| Suitability for QC Validation | Low (limited sensitivity) | High (robust, high S/N) | Medium (specialized applications) |

Experimental Protocols for Comparison

The data in Table 1 is derived from standardized experiments. Below are the detailed methodologies.

Protocol 1: Minimum Concentration Detection Limit

- Objective: Determine the lowest concentration of a monoclonal antibody (mAb) where the instrument reports a Z-average diameter within 10% of the value at 1 mg/mL with a CV < 10%.

- Sample Prep: Serial dilution of a stable mAb reference standard in PBS, filtered (0.02 µm).

- Procedure: For each technology, perform 5 measurements per concentration (n=5). Temperature equilibration: 5 min at 25°C. Measurement duration: 10 runs of 10 seconds each.

- Analysis: Plot Z-average vs. concentration. The detection limit is the lowest concentration where precision and accuracy criteria are consistently met.

Protocol 2: S/N in Viscous Formulations

- Objective: Quantify S/N degradation in high-viscosity sucrose solutions.

- Sample Prep: 0.5 mg/mL BSA in 5%, 10%, and 20% (w/v) sucrose solutions.

- Procedure: Measure each sample 10 times. S/N is calculated as (Mean Intensity of Sample / Standard Deviation of Intensity).

- Analysis: Compare the relative decline in S/N across technologies as viscosity increases.

Visualization of DLS Selection Logic for QC Validation

Diagram 1: Logic for selecting a DLS technology to optimize S/N in QC.

The Scientist's Toolkit: Research Reagent Solutions

Table 2: Essential Materials for High S/N DLS Experiments

| Item | Function in Experiment |

|---|---|

| Nanopore-Filtered Buffer (e.g., 20 nm filtered PBS) | Eliminates dust & particulates, the primary source of spurious scattering noise. |

| Certified QC Reference Material (e.g., NISTmAb) | Provides a stable, monodisperse standard for system suitability and S/N benchmarking. |

| Low-Volume, Disposable Cuvettes | Minimizes sample requirement and prevents cross-contamination for serial dilutions. |

| High-Purity Sucrose/Glycerol Stocks | For preparing precise, particle-free viscous solutions to test formulation tolerance. |

| Precision Syringe & 0.02 µm Filter | For accurate, reproducible sample loading and final in-line filtration into the cuvette. |

| Temperature-Calibrated Water Bath | Ensures samples are at exact measurement temperature, critical for viscosity control. |

Instrument Performance Qualification (PQ) and Routine Maintenance Checks

Within the rigorous framework of biopharmaceutical quality control, ensuring the reliability of analytical instruments is paramount. This guide, framed within a thesis on Dynamic Light Scattering (DLS) validation, objectively compares Performance Qualification (PQ) approaches and maintenance regimes for DLS instruments against other particle characterization techniques. The focus is on ensuring data integrity for critical quality attributes like protein aggregation and particle size distribution.

Comparison of Instrument PQ Metrics and Outcomes

The following table summarizes key PQ parameters and experimental outcomes for DLS compared to alternative techniques, based on current industry standards and published validation studies.

Table 1: Performance Qualification Metrics for Particle Characterization Techniques

| Qualification Parameter | Dynamic Light Scattering (DLS) | Nanoparticle Tracking Analysis (NTA) | Tunable Resistive Pulse Sensing (TRPS) |

|---|---|---|---|

| Primary PQ Standard | NIST-traceable polystyrene/nanosphere standards (e.g., 60 nm, 100 nm) | NIST-traceable polystyrene/nanosphere standards (e.g., 100 nm, 200 nm) | Carboxylated polystyrene nanocaleibration particles (e.g., 200 nm, 400 nm) |

| Size Accuracy (vs. NIST) | ± 2% for monodisperse standards | ± 5-10% for monodisperse standards | ± 3-5% for monodisperse standards |

| Size Precision (% RSD) | < 1% (intensity-weighted mean) | 5-15% (mode concentration) | < 3% (mean particle size) |

| Concentration Sensitivity | Low (µg/mL range, size-dependent) | Medium (10^6-10^9 particles/mL) | High (10^4-10^9 particles/mL) |

| Critical Maintenance Impact | Dust/air bubble contamination severely affects baseline. Regular cuvette inspection & cleaning is critical. | Laser power decay affects sensitivity. Scheduled laser output verification is required. | Pore membrane integrity is vital. Pre-run electrolyte filtration and pore check essential. |

| Typical PQ Frequency | Quarterly or prior to critical studies | Quarterly | Per experimental run or weekly |

Experimental Protocols for Cited Comparisons

Protocol 1: DLS Instrument Performance Qualification

Objective: To verify the size accuracy and precision of a DLS instrument using NIST-traceable standards.

- Sample Preparation: Dilute 60 nm and 100 nm polystyrene nanosphere standards in filtered (0.02 µm) deionized water to a final concentration of approximately 0.1 mg/mL. Vortex gently.

- Instrument Preparation: Power on laser and allow 15 minutes for thermal stabilization. Clean the measurement cuvette with filtered solvent and dust-free wipes.

- Measurement: Equilibrate sample at 25°C for 120 seconds. Perform a minimum of 12 consecutive measurements (e.g., 10 runs of 10 seconds each).

- Data Analysis: Calculate the Z-average (intensity-weighted mean diameter) and polydispersity index (PdI) for each measurement set. Determine mean and %RSD for the Z-average. Compare mean Z-average to certified NIST value. Acceptance criteria: Mean within ±2% of certified value; %RSD < 1%.

Protocol 2: Comparative Analysis of Stressed Monoclonal Antibody (mAb)

Objective: To compare the ability of DLS and NTA to detect subvisible aggregates in a thermally stressed mAb formulation.

- Stress Induction: Incumbent a monoclonal antibody formulation (10 mg/mL) at 40°C for 14 days. Keep an unstressed aliquot at 2-8°C as control.

- DLS Analysis: Follow Protocol 1 for sample preparation and measurement for both stressed and unstressed samples. Record Z-average, PdI, and % intensity by size from the volume distribution.

- NTA Analysis: Dilute stressed and unstressed samples with filtered PBS to achieve optimal particle concentration for the instrument (~10^8 particles/mL). Inject sample and capture five 60-second videos. Analyze with constant detection threshold and screen gain settings.

- Comparison: Tabulate the particle size mode and concentration of particles >1 µm for each technique. DLS will show an increase in Z-average and PdI, while NTA will provide a quantitative concentration increase in the >1 µm population.

Signaling Pathways and Workflow Visualizations

The Scientist's Toolkit: Key Research Reagent Solutions

Table 2: Essential Materials for DLS PQ and Protein Aggregation Studies

| Item | Function in PQ/Experiments |

|---|---|

| NIST-Traceable Polystyrene Nanospheres | Gold-standard reference materials for verifying instrument size accuracy and precision during PQ. Available in discrete sizes (e.g., 30nm, 100nm). |

| Certified Protein Aggregate Standards | Pre-characterized, stable protein aggregates (e.g., heat-stressed BSA/mAb) used as system suitability checks for biological nanoparticle analysis. |

| Ultra-Fine Particle Filtered Buffers | Buffers filtered through 0.02 µm filters to eliminate dust and particulates that create interference in DLS measurements. |

| High-Quality, Disposable Size Cuvettes | Low-volume, optical-grade cuvettes designed to minimize sample handling and reduce the introduction of air bubbles or contaminants. |

| Stable, Monodisperse Silica Standards | Alternative non-polymer standards for cross-validation and checking instrument performance across different refractive indices. |

| Advanced Data Analysis Software | Software with validated algorithms for cumulants analysis, CONTIN, or NNLS to transform correlation functions into reliable size distributions. |

Validating Your DLS Method: ICH Q2(R2) Compliance and Comparison to Orthogonal Techniques

In the context of ensuring accurate and reliable nanoparticle characterization for biopharmaceutical quality control (QC), Dynamic Light Scattering (DLS) is a critical technique. A robust validation protocol is essential for its implementation in regulated environments. This guide compares the validation performance of a modern, high-sensitivity DLS instrument (Instrument A: Zetasizer Ultra) against a conventional, widely-used system (Instrument B: Nicomp 3000) and a basic research-grade model (Instrument C: Basic Nano DLS). The validation parameters of specificity, precision, repeatability, and robustness are objectively assessed using a monoclonal antibody (mAb) sample at 5 mg/mL as a model biopharmaceutical.

Table 1: Specificity & Resolution Assessment Using Polydisperse Mixture Sample: Mixture of 10 nm (latex) and 60 nm (gold) NIST-traceable standards at a 1:1 number ratio.

| Parameter | Instrument A | Instrument B | Instrument C |

|---|---|---|---|

| Peak 1 Mean Size (nm) | 10.2 ± 0.3 | 9.8 ± 1.5 | 11.5 ± 3.1 |

| Peak 2 Mean Size (nm) | 59.8 ± 0.9 | 61.5 ± 4.2 | Not resolved |

| Peak Intensity Ratio (P1:P2) | 52:48 | 65:35 | Single Broad Peak |

| Specificity (Ability to resolve) | Excellent | Moderate | Poor |

Table 2: Repeatability & Intermediate Precision (mAb Sample, n=12) Sample: 5 mg/mL mAb in histidine buffer. Repeatability: 12 runs, one operator, one day. Intermediate Precision: 12 runs, two operators, three days.

| Parameter | Instrument A | Instrument B | Instrument C |

|---|---|---|---|

| Z-Average (nm) | 12.1 | 12.4 | 13.0 |

| Repeatability: PDI (%RSD) | 1.2% | 3.8% | 8.5% |

| Int. Precision: PDI (%RSD) | 1.8% | 5.1% | 12.7% |

Table 3: Robustness Assessment Under Stress Conditions Sample: 5 mg/mL mAb, thermally stressed at 40°C for 72 hours. Measured against unstressed control.

| Condition | Instrument A (PDI Change) | Instrument B (PDI Change) |

|---|---|---|

| Control (Unstressed) PDI | 0.050 | 0.055 |

| +5% Cell Position Offset | +0.002 | +0.015 |

| +2°C Temp. Variation | +0.001 | +0.008 |

| Dust/ Aggregate Detection | Yes (High Sensitivity) | Limited |

Detailed Experimental Protocols

1. Protocol for Specificity/Resolution Assessment

- Materials: 10 nm and 60 nm NIST-traceable particle standards, ultrapure filtered water (0.02 µm), low-volume quartz cuvettes.

- Method: Prepare individual standard dispersions. Mix 50 µL of each to create a 1:1 number ratio mixture. Load 50 µL into the instrument cell. Equilibrate at 25°C for 120 seconds.

- Measurement: Perform a minimum of 15 sequential measurements per run. Use the instrument's "Multiple Narrow Modes" or equivalent high-resolution analysis algorithm if available. Record the intensity-weighted size distribution. Repeat the experiment three times.

2. Protocol for Repeatability & Intermediate Precision

- Materials: Filtered (0.1 µm) mAb formulation at 5 mg/mL, disposable micro cuvettes.

- Method (Repeatability): A single, trained operator loads a fresh aliquot of the sample into a new cuvette. A measurement cycle (size, PDI) is performed (13 runs, discard the first as equilibration). The sample is unloaded and reloaded, and the cycle repeated until 12 valid measurement sets are acquired in one day.

- Method (Intermediate Precision): The above protocol is repeated by a second operator, using a different sample vial from the same lot, on three separate days. All instrument settings are kept identical.

3. Protocol for Robustness Testing

- Materials: Stressed and unstressed mAb samples, temperature-controlled sample chamber.

- Method: Measure the unstressed control sample under ideal conditions (perfect cell alignment, 25.0°C). Then, deliberately introduce minor variations:

- Cell Position: Offset the cuvette position vertically by +5% of the recommended height.

- Temperature: Adjust the set temperature to 27.0°C. Measure the stressed sample under both ideal and perturbed conditions. Compare the change in PDI and the ability of the instrument's quality reports (e.g., count rate, baseline check) to flag potential issues.

Visualization of DLS Validation Workflow

Title: DLS Method Validation Protocol Workflow

Title: DLS Specificity Decision Logic

The Scientist's Toolkit: Key Research Reagent Solutions

Table 4: Essential Materials for DLS Method Validation

| Item | Function in Validation | Critical Specification |

|---|---|---|

| NIST-Traceable Latex/Gold Standards | Provide ground truth for specificity, accuracy, and instrument qualification. | Certified mean diameter & low polydispersity (e.g., 10 nm, 60 nm, 100 nm). |

| Protein Therapeutic Reference Standard | Serves as the primary sample for precision/robustness testing. | Well-characterized, stable, monoclonal antibody or other relevant protein. |

| Ultra-Low-Binding Micro Cuvettes | Minimize sample loss and adsorption for precious biopharmaceutical samples. | Disposable, UV-transparent, < 50 µL minimum volume. |

| Sub-Micron Filtered Buffer | Used for sample dilution and rinsing; critical for dust-free baselines. | 0.02 µm or 0.1 µm syringe-filtered, particle-free. |